CNC blade cutting machines are widely used in industries such as packaging, textiles, automotive, aerospace and signage. They offer precise and efficient cutting capabilities, capable of producing complex shapes and patterns with minimal material waste.

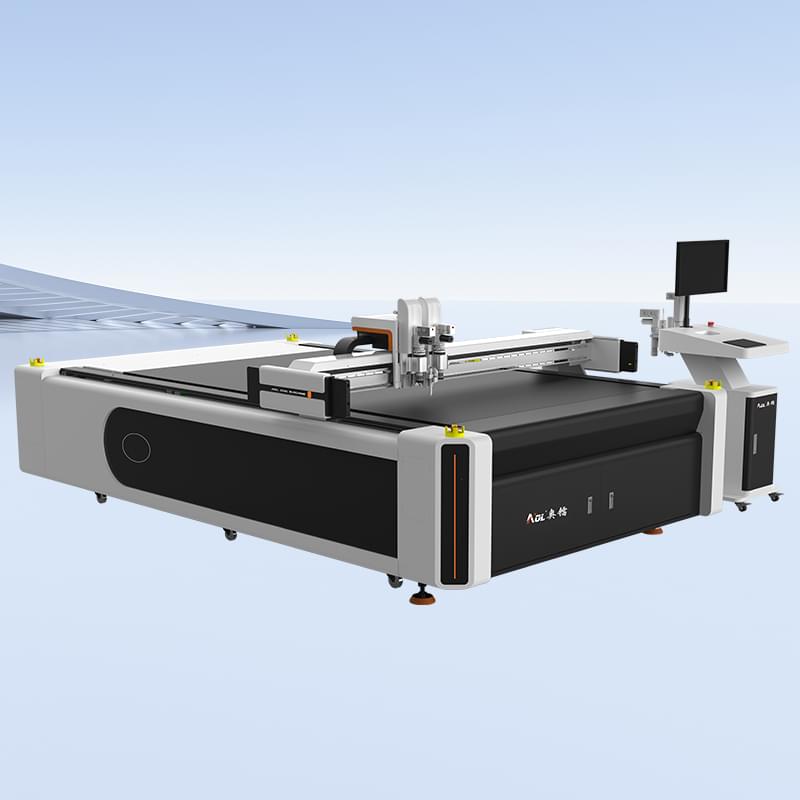

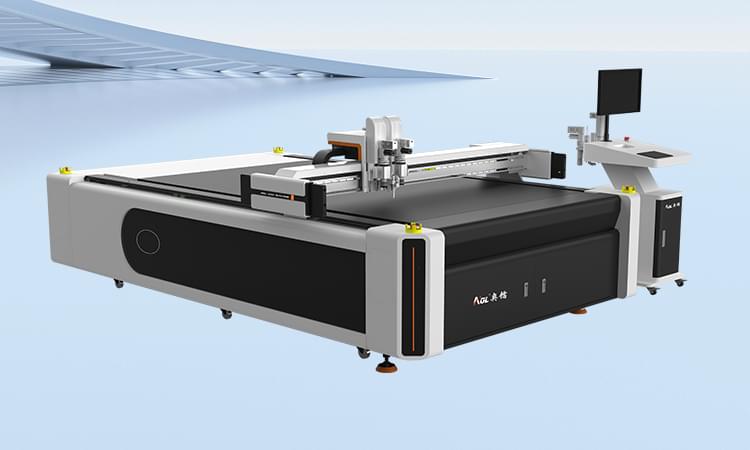

CNC blade cutting machine, also known as CNC cutting machine or CNC vibrating knife cutting machine, is a computer-controlled cutting system designed specifically for precision cutting of various materials. It utilizes a vibrating or oscillating knife that moves up and down rapidly to cut the material.

There are two types of economical CNC vibration knife machines: ① CNC engraving machine plus vibration knife cutting head (the knife and the spindle work independently, compatible with the CNC engraving machine control system, run perfectly, and solve the processing needs of soft materials); ② Professional vibration knife cutting machine (professional and efficient). According to the function: it can be divided into vibration knife cutting, circular knife cutting, and pneumatic knife cutting. Choose different knives according to the shape of the cutting material.

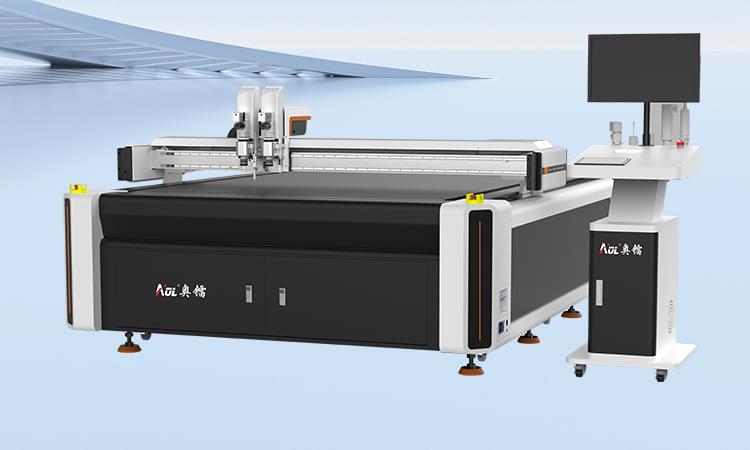

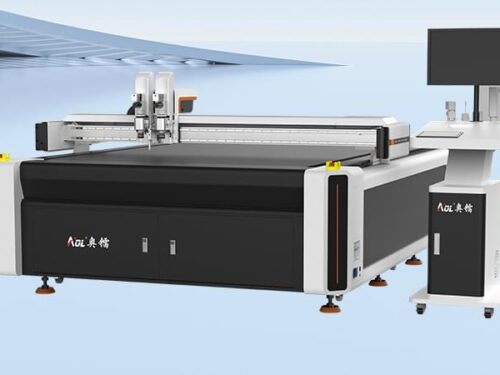

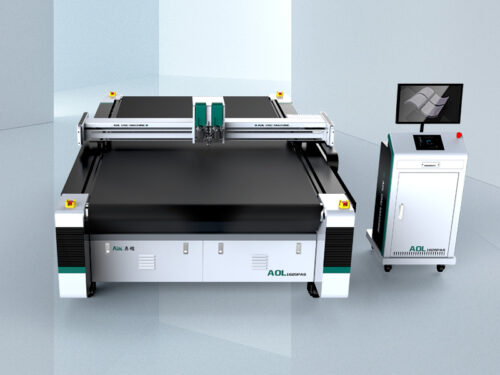

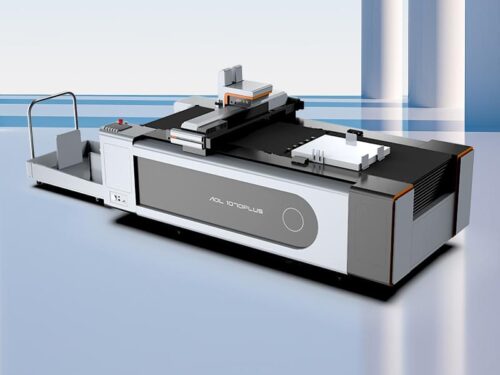

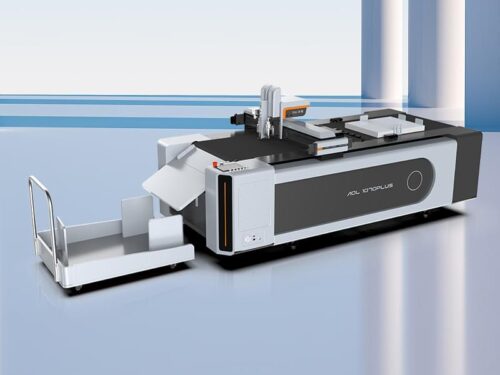

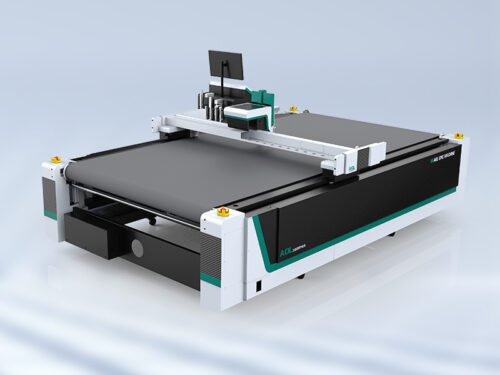

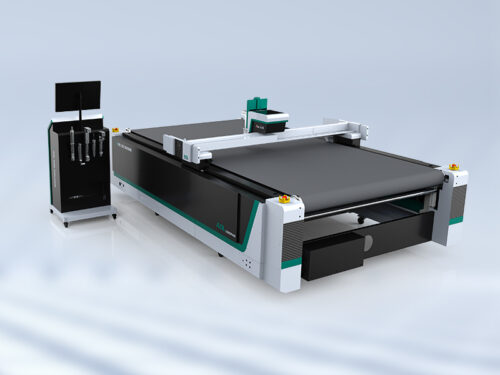

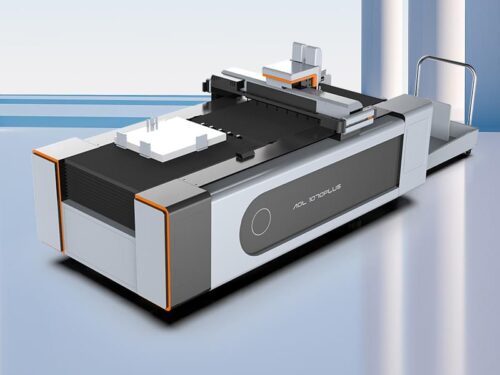

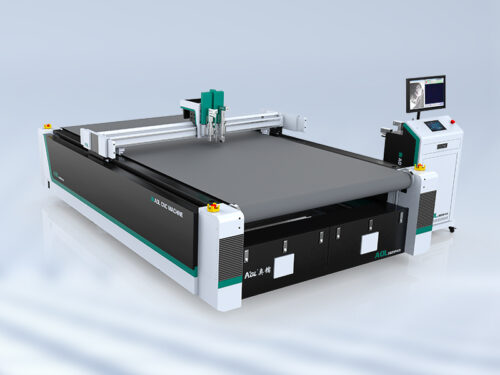

AOL offers a variety of CNC vibration knife cutting machines for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

Automatic feeding series: automatic loading and unloading; intelligent layout; multi-layer cutting.

Multi-head series: double heads can cut the same shape or different shapes at the same time.

6 advantages of using CNC blade cutting machine to cut flexible materials:

1. More flexible: The automatic cutting machine does not need a mold. It only needs to process the processing data (PLT, DXF, AI format) into the system for cutting, and the size and shape of the processed graphics can be modified at will;

2. Save materials: The automatic typesetting software can complete the typesetting quickly and accurately without manual typesetting. After actual testing, the use of automatic cutting machine can save more than 10% of materials compared with manual cutting;

3. Meet the cutting of different foams: It can cut foams of different widths, thicknesses, and materials with high cutting accuracy and smooth cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humane: The CNC blade cutting machine adopts high-frequency vibration knife cutting technology. Compared with laser cutting technology, there is no smoke and dust at the processing site, and the cutting speed is 3-4 times that of laser, which is a more environmentally friendly processing method.

5. Different types of cutters can be configured: Customers can configure different processing cutters according to the processing materials – circular cutters, pneumatic cutters, punching cutters, vibration cutters and other cutter heads, which can be freely configured to cut other materials except foam;

6. Achieve higher cutting efficiency: Using imported servo motors, the cutting speed can reach 2000mm/s. Customers can also choose dual swing cutters to cut at the same time, which doubles the processing efficiency.

In addition to the oscillating knife, CNC tool cutting machines can often accommodate other cutting tools or accessories that expand their capabilities. Some common additional tools include:

Creasing Wheel: Used to create creases or score lines in materials like cardboard or paper to make them easier to fold or bend.

Perforation Wheel: Used to create perforation lines in materials like paper or cardboard for tearing off sections.

Routing Attachment: Used to cut harder materials (like acrylic or wood) where an oscillating knife might not be suitable.

The ability to interchange tools allows for greater flexibility in the types of materials and applications the machine can handle.

CNC tool cutting machines streamline the cutting process, reduce manual labor and increase production efficiency. Once the cutting program is set, the machine can perform the cutting task autonomously, optimizing material usage and minimizing waste. This automation can also reduce turnaround time, allowing manufacturers to meet tight deadlines and handle larger production volumes.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.