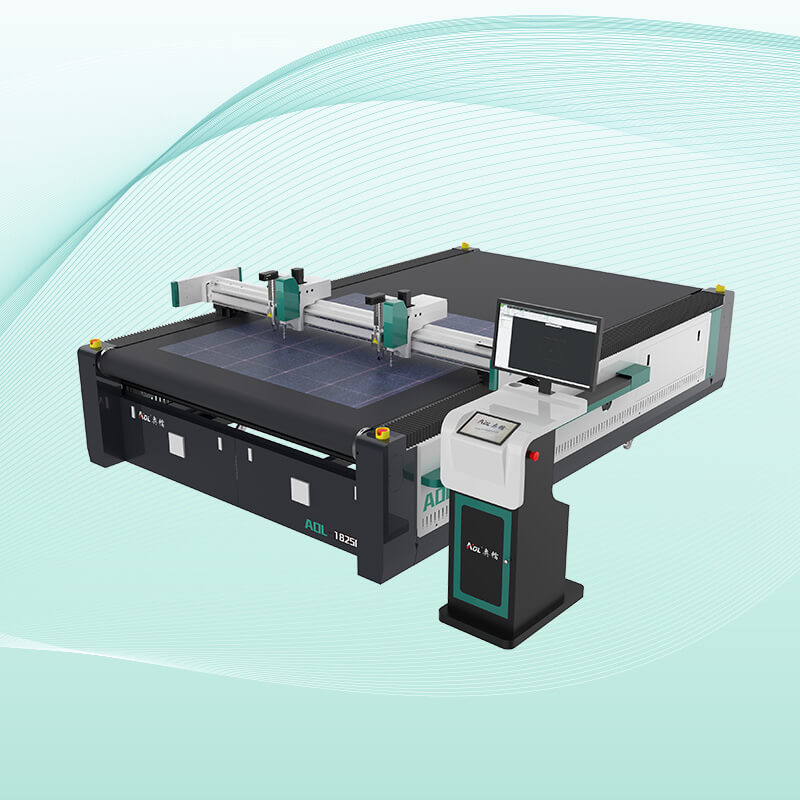

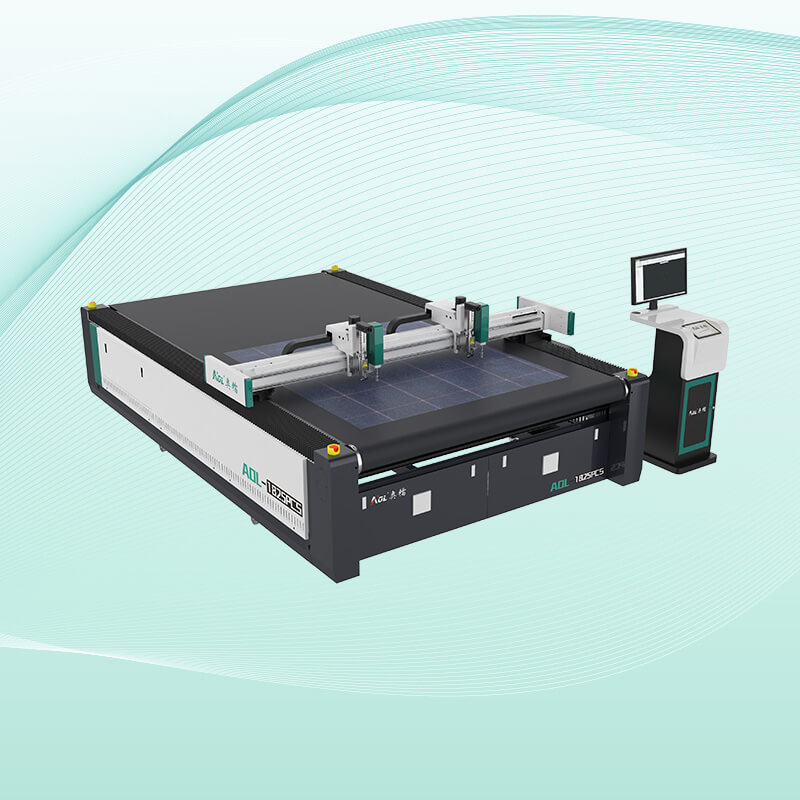

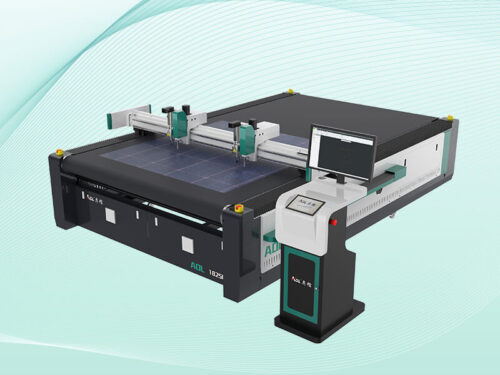

Features of Digital Acoustic Board Cutting Machine

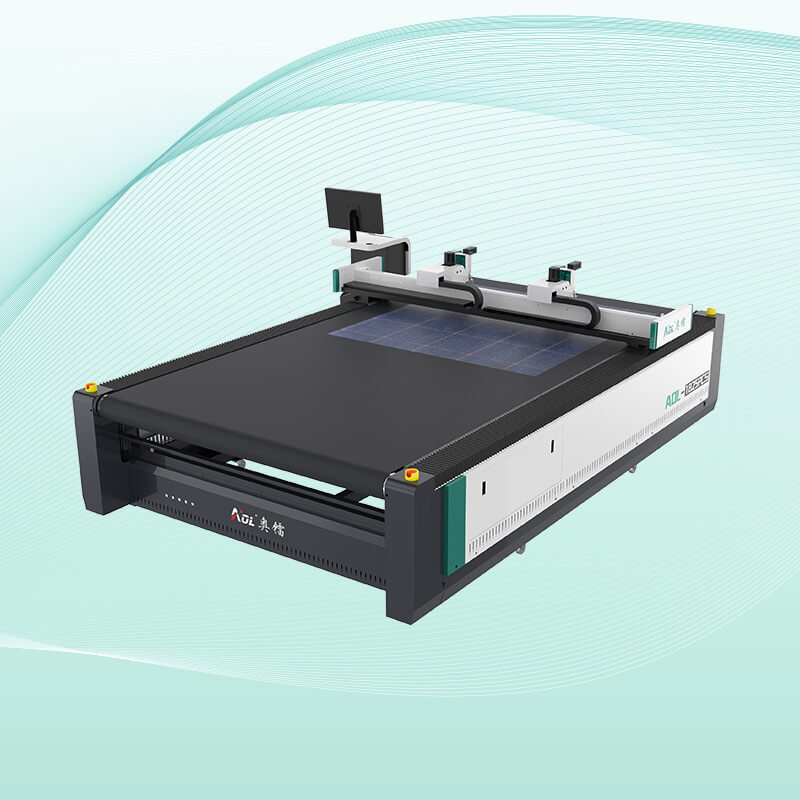

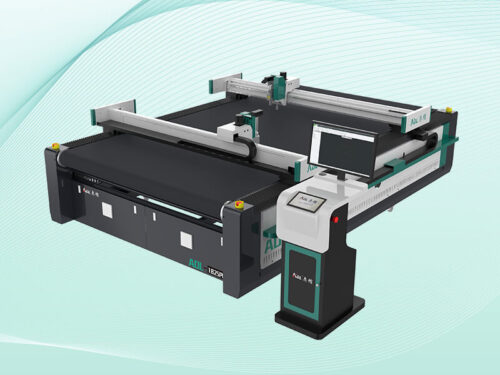

1.Table length break through the traditional limit,transport and installation is much easier.

2.Full automatical feeding with the function of automatic rectifying voluntarily, reduce labour, increase efficiency.

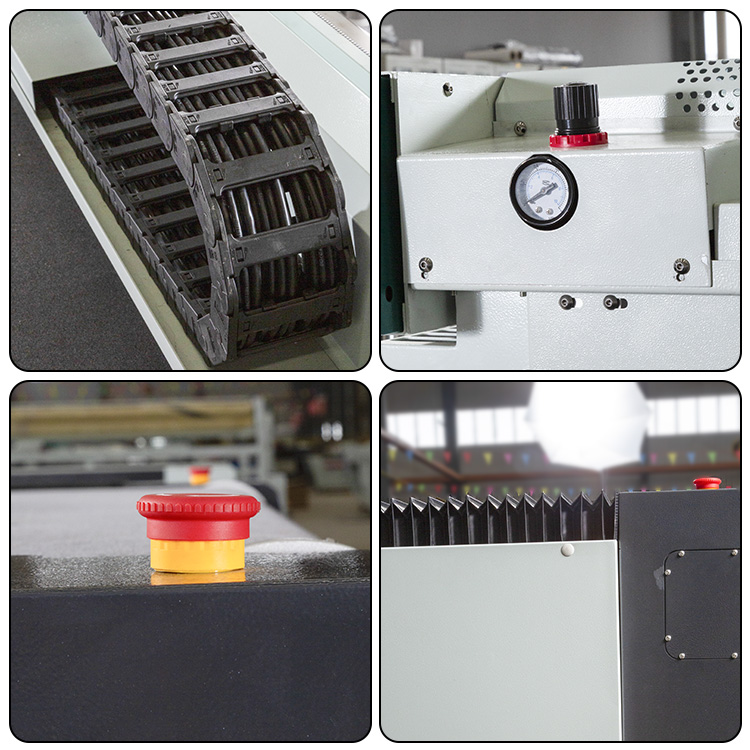

3.The rack is welded with high stability.

4.Double mute guide rail.Honey comb platform.

5.Servo motor, Japanese imported parts, infrared device.

Application of Digital Cutting Machine for PET Acoustic Board Panels

Nowadays, whether it is residential or commercial factories, the requirements for sound insulation conditions are getting higher and higher, so the market for the sound insulation and heat preservation industry is increasing, but the cutting of sound insulation and heat preservation materials has become a pain point for many manufacturers.

AOL Digital Cutting Machine for PET Acoustic Board Panel just solves the problem of cutting sound insulation materials.

It can cut sound insulation materials of different thicknesses and shapes.

Multi-purpose machine can also cut other materials : Leather(natural leather,synthetic leather for multi-layer cutting),fabric(woven and knit fabric for multi-layer cutting),gasket,KT board,carbon fiber prepreg…

Other material–welcome send the sample to test with our machine.

Advantage of Digital Cutting Machine for PET Acoustic Board Panels

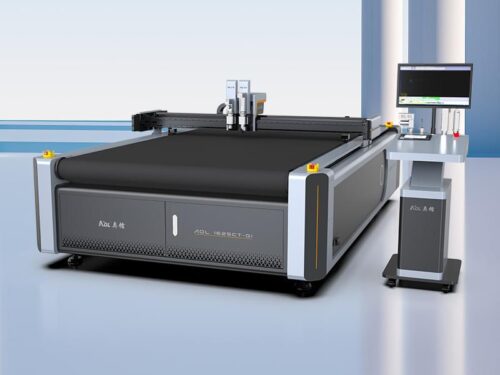

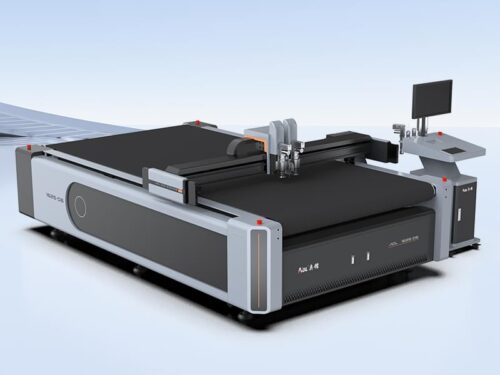

1. Digital Cutter for PET Acoustic Board PanelsCutting by knife not laser, no air pollution , no burnt edge, cutting speed is 5-8 times faster than laser cutting machine.

2. Imported square linear guide and Japanese servo motor ensure high precison and fast cutting speed.

3. The application of an Ethernet port makes the cutting plotters fast and convenient.

4. This Digital Cutting Machine for PET Acoustic Board Panels was designed easy to install, set-up and operate.

5. Special safety sensing device meets the European standard.

6. Digital Cutting Machine for PET Acoustic Board Panels can equipped with different tools to meet a variety of need

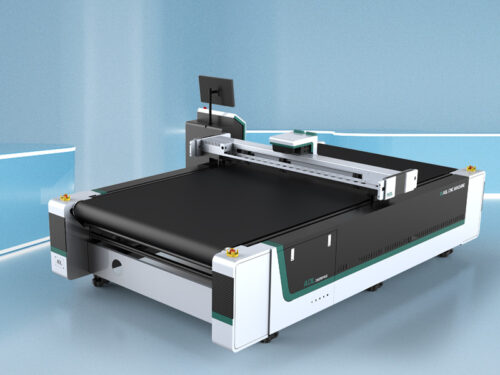

Specifications of Digital Cutting Machine for PET Acoustic Board Panels

| Technical parameters | AOL-FH1625-PS, AOL-FH1825-PS, |

|---|---|

| Effective working area | 1600*2500MM, 1800*2500MM |

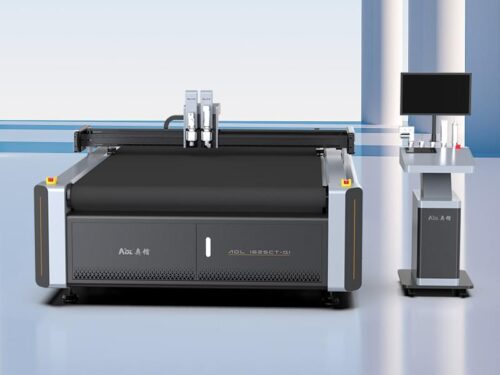

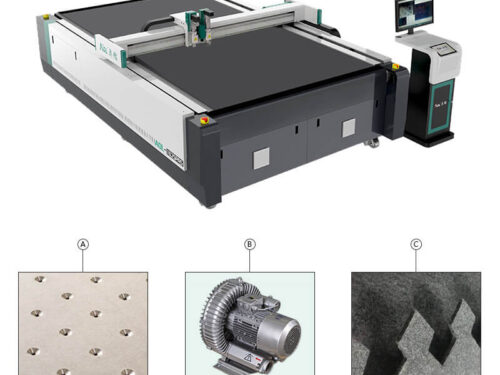

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

| Tools | Universal Drawing Tool, Creasing Wheel Tool |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.05mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

| Cutting material | PET, Acoustic Board Panels, Glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, boron fiber, aramid fiber, ceramic fiber, soft glass, PVC, leather leather, sponge composite skin, XPE material, wire ring, leather, soft glass , silicone, rubber material etc composite soft material, etc. |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

Why Choose Digital Cutting Machine for PET Acoustic Board Panels

Customer pain points in the Acoustic Board Panels Industry

1.The hardness of special materials is extremely high, which cannot be achieved by traditional cutting.

2. The price of raw materials is expensive, and the waste rate of manual cutting is high

3. The utilization rate of manual discharge is too low, which increases the cost of the enterprise

4. High-end products have high technical requirements, which cannot be achieved by traditional craftsmanship

5. Special materials have occupational hazards to the human body

Choosing Digital Cutting Machine for PET Acoustic Board Panels can solve the above difficulties

1.The manual cutting error is large, the efficiency is low, and the subsequent workload is increased.

2. AOL rapid tool exchange system provides a variety of cutting tool options for various materials

3. Super nesting software, material utilization rate increased by more than 10%

4. Select Japanese Panasonic servo system to increase production efficiency by more than five times

5. Automatic pulling and unloading, saving time, effort and more environmental protection

6. The anti-static system of the whole machine to maximize the protection of personnel safety

Service OF AOL

1.Three years warranty,main parts are free of charge when problems happened during the guarantee period.

2.We provide the consumable parts at agent price when you need replacement

3.24 hours online service each day,free technical support with different languages.

4.We provide door to door technical support ,if necessary.

FAQ Of Digital Cutting Machine for PET Acoustic Board Panels

AOL is one of the famous professional carbon fiber cutting machine manufacturers and suppliers in China,Choose Digital Cutting Machine for PET Acoustic Board Panels is right.If you need it, please contact us.

Question 1: I want to buy this machine,what suggestion can you give?

Answer: Please tell me:what material do you process? What’s the size of your material?

Question 2: What’s the delivery cost & time?

Answer: Please tell me your sea port name,i check shipping cost. After production,we’ll deliver ASAP.

Question 3: Have you exported to our country?

Answer: We have been in this field for 10 years,we have CE,ISO,FDA certificates,have exported to Europe,South America,Arab,Asia,Russia,Spain,Australia and many more countries.

Question 4: This is the first time I use this kind of machine, is it easy to operate?

Answer:There are english manual or guide video that show how to use machine.

If there is still have any question, please contact us by e-mail / skype/ phone /trademanager online service at any time.

Question 5: If machine have any problem after I receive it, how can I do ?

Answer:Free parts send to you in machine warranty period if machine have any problem. If the parts less than 0.5KG, we pay the postage.

About AOL

AOL CNC Equipment Co., Ltd. is a high-tech enterprise specializing in the development, manufacturing, sales and after-sales service of flexible material cutting and laser cutting machines, mainly including CNC intelligent blade cutting machines. Various types of cutting machines such as labeling machines can meet the cutting different materials, and are widely used in advertising packaging, composite materials, carpet industries, clothing textiles, automotive interiors, and leather industries.

In addition, AOL also has an independent CNC cutting machine brand AOYOO.

The company is strong. AOL CNC Equipment Co., Ltd. is a high-tech industry in China and an AAA-level credit enterprise. The product quality has undergone multiple tests and the after-sales system is complete.

It has provided reliable CNC cutting machines for more than 25000 users worldwide. Provide professional industry cutting assembly line solutions for many users,

AOL is committed to multi-industry flexible material cutting solutions for global users. The annual output of high-quality CNC cutting machines in the AOL factory can reach 2000 units, and each machine is provided with a three-year warranty service.

There are many machine models produced by AOL, such as carton cutting machine, fabric cutting machine, gasket cutting machine and so on. Welcome to learn more.

Please leave your contact information, and briefly describe the thickness and size of your cutting material, we will recommend a suitable model for you.

MESSAGE

CONTACT

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

+86-531-88620680

+86-531-88620680

0086-18560162709

0086-18560162709

+86-531-88620680

+86-531-88620680

Reviews

There are no reviews yet.