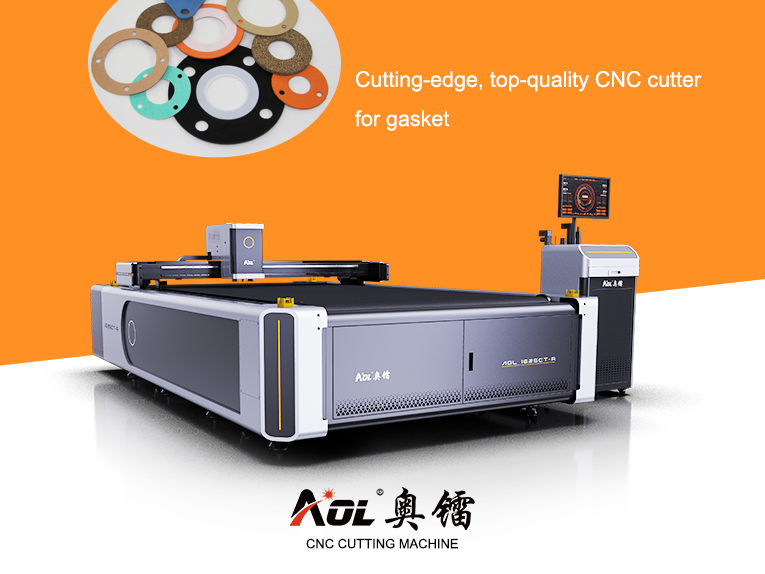

CNC technology has become a cornerstone of the PTFE gasket industry, enabling manufacturers to meet the growing demand for complex and custom-shaped gaskets. Traditional cutting methods, such as manual cutting and die cutting, often struggle to achieve the precision and consistency required for modern applications. However, CNC technology makes up for this shortcoming by automating the cutting process and ensuring a high level of accuracy.

Going from traditional methods to CNC technology represents a significant change. Initially, PTFE gasket manufacturers relied heavily on manual techniques that were time-consuming and prone to human error. Die cutting, while faster, required expensive dies and lacked the flexibility to produce custom shapes without additional tooling. CNC technology eliminates these limitations with computer-controlled cutting paths, making it easy to cut complex designs with precision.

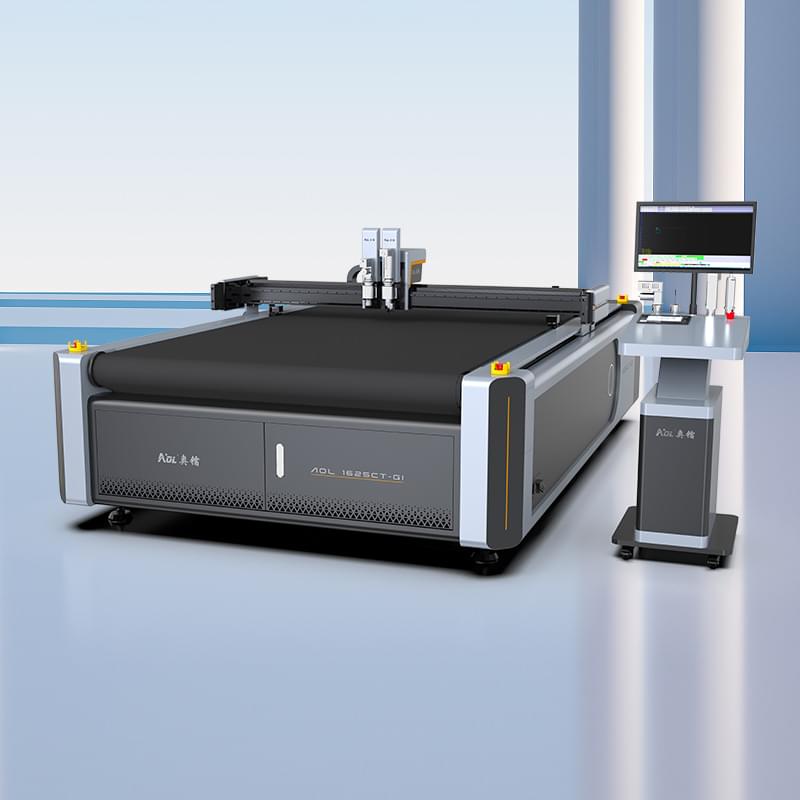

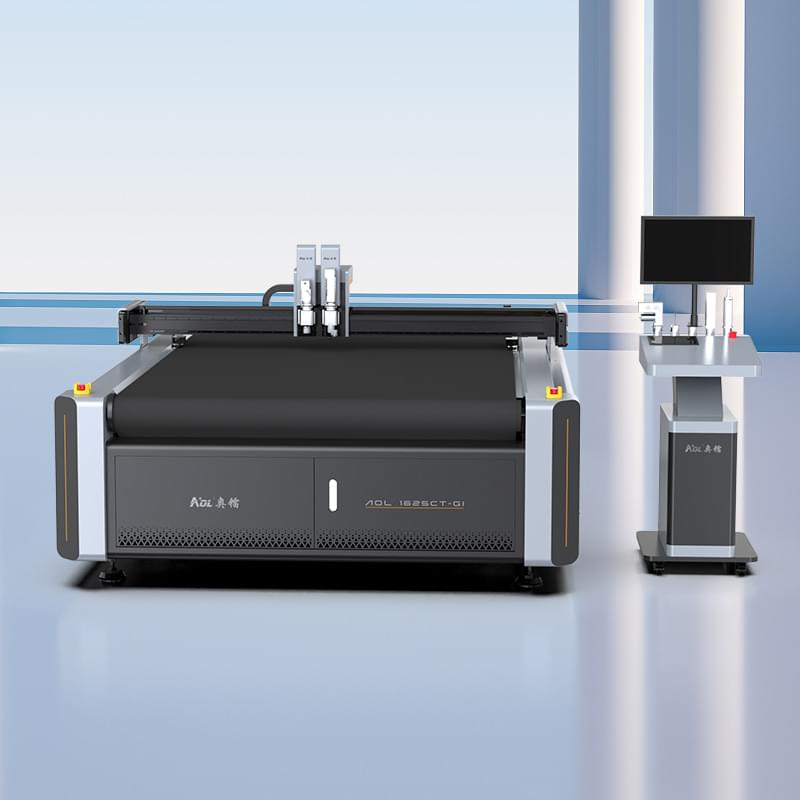

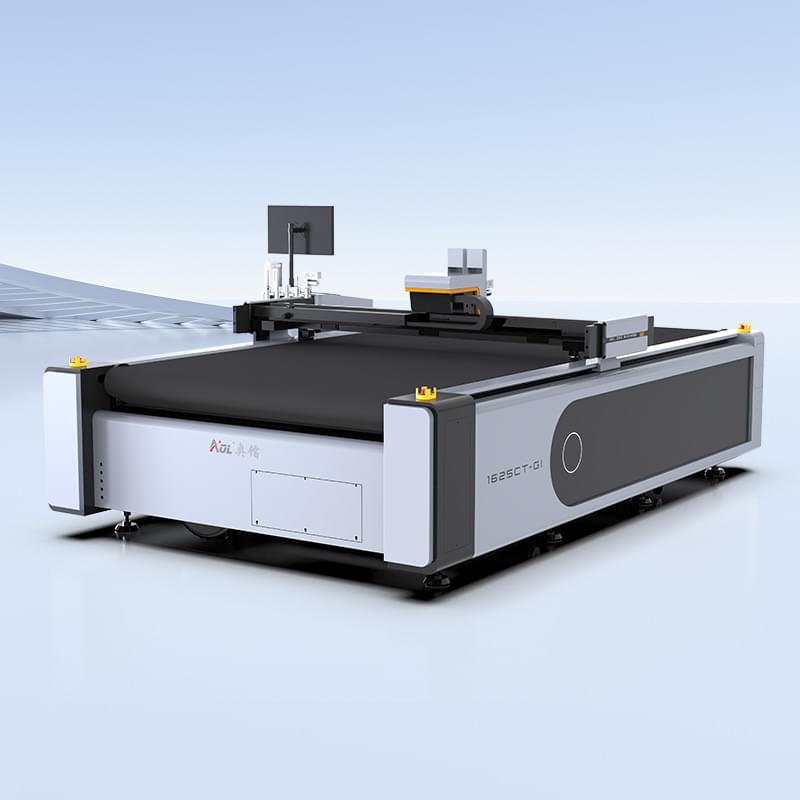

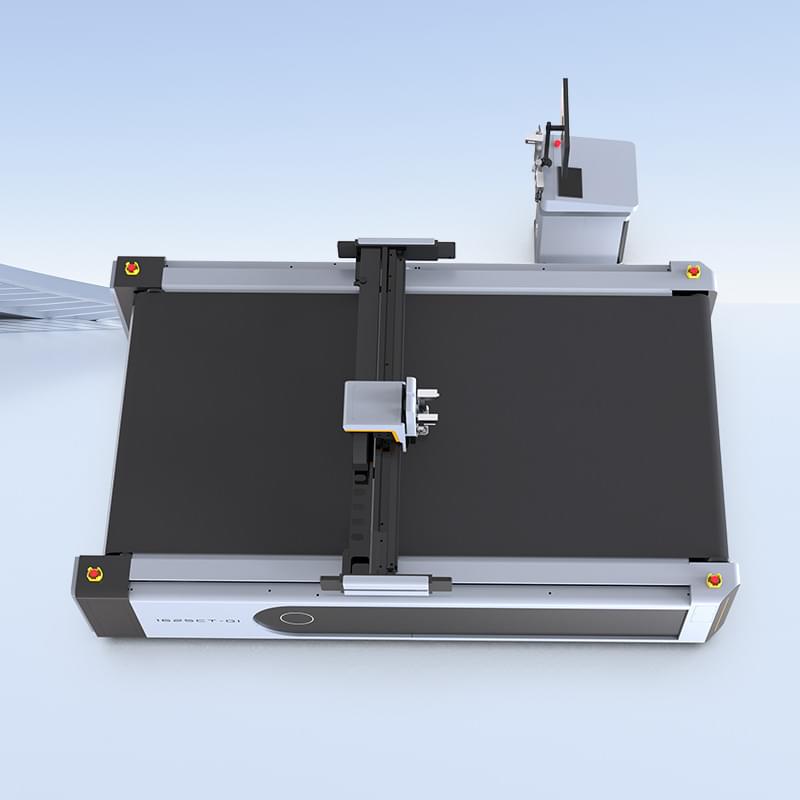

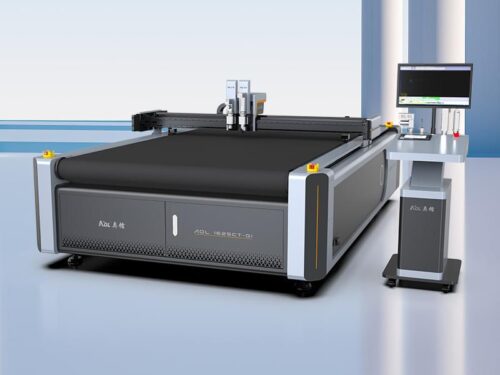

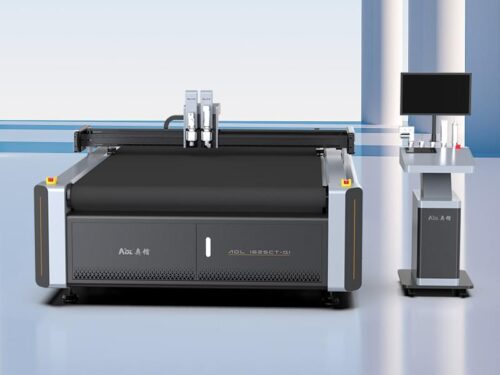

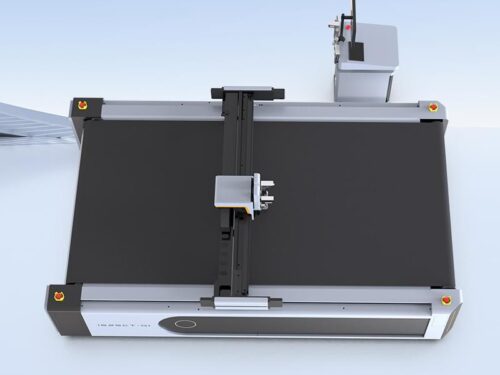

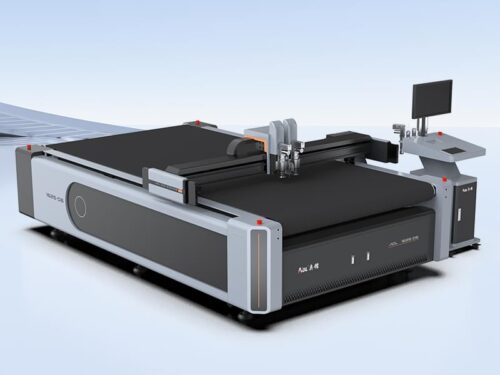

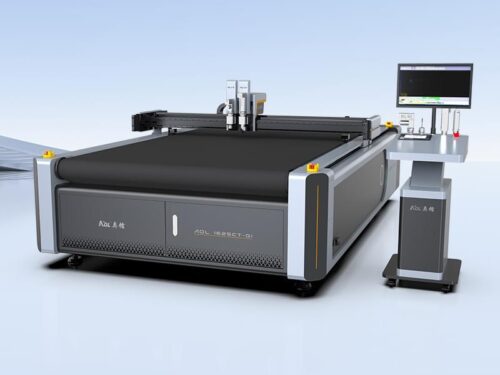

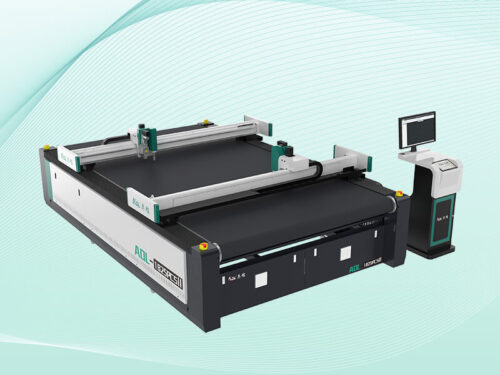

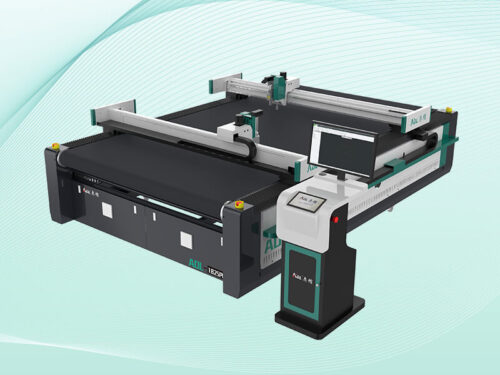

Parameters of CNC PTFE sealing gasket cutting machine:

| TECHNICAL PARAMETERS / MODEL | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | ACCEPTING SPECIAL-SHAPED CUSTOMIZATION |

|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500mm | |

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, semi-cutting cutting, full cutting cutting, camera positioning cutting, edge finding cutting, acrylic milling cutter, cursor positioning, line marking, indentation knife, V-groove knife, etc. | |||

| safety devices | Infrared sensing, safe and reliable | |||

| Cutting speed | 200-2000mm/s | |||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||

| Applicable materials | Various KT boards, Chevron boards, honeycomb boards, car stickers, adhesives, photo frame paper, gray board paper, corrugated paper, EPE foam, PVC board, acrylic sheet, thick foam, etc. | |||

| Material fixing method | Vacuum partition adsorption | |||

| Transmission port | Network port | |||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||

| rated power | 11kw | |||

| Rated voltage | 380V±10%/220V±10%Optional | |||

| Control System | Chinese and English LCD touch screen | |||

| Operating environment | Temperature 0-40°C Humidity 20%-80%RH | |||

| software | Automatic nesting software, camera positioning, large format camera system | |||

| Support file format | AI、PLT、DXF、CDR etc. | |||

Digital Knife cutting machines can be equipped with different types of blades, depending on the specific requirements of the PTFE cutting task. This adaptability enables the machine to handle different thicknesses of PTFE without compromising the quality of the cut. The resulting wear-free cuts are essential for applications that require a tight seal or a smooth surface. Unlike laser cutting, which can cause thermal deformation or melting of certain materials, the Digital Knife cutting process is non-thermal. This means that the integrity of the PTFE material is maintained, avoiding any potential warping or degradation due to heat. Digital Knife cutting machines can easily cut PTFE sheets ranging from 1 mm to 5 mm in thickness. Cutting parameters such as speed and blade type can be adjusted according to thickness to ensure a clean, precise cut without damaging the material.

Let’s take a look at how the CNC PTFE sealing gasket cutting machine works!

The automation and precision of CNC PTFE gasket cutting machines significantly improves production efficiency. By reducing the time required to set up and perform cuts, these machines can shorten production cycles. In addition, the precision of CNC cutting minimizes material waste because each cut is optimized to make the best use of available material. This not only reduces costs, but also contributes to more sustainable manufacturing practices.

Our PTFE gasket cutting machines are suitable for customization from small batches to large batch orders. Whether the customer needs a single custom gasket or a large batch production, the CNC machine can complete the task with minimal downtime. This feature is particularly beneficial for manufacturers serving industries with highly specific and diverse needs, such as the automotive, aerospace and industrial sectors.

After sale service

Eight reasons to AOL CNC cutting machine

1. Advanced brand: ten years of professional CNC blades2. R & D advantages: a number of patented technologies, so that the company has a deep deposit

3. Quality assurance: all products have passed European CE certification. US FDA certification

4. High-quality materials: All CNC cutting machine accessories are selected from industry-leading brands.

5. Advanced technology: starting from Germany, foreign advanced technology, technical support

6. High efficiency: implement one-to-one service to improve the efficiency of corporate feedback

7. Personalized customization: With the development and design functions, customers can do whatever they want

8. After-sales service: provide three-year warranty service and 24-hour online solutions.

AOL company info

Welcome to join AOL, we will share top-level machines and services with customers all over the world.

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.