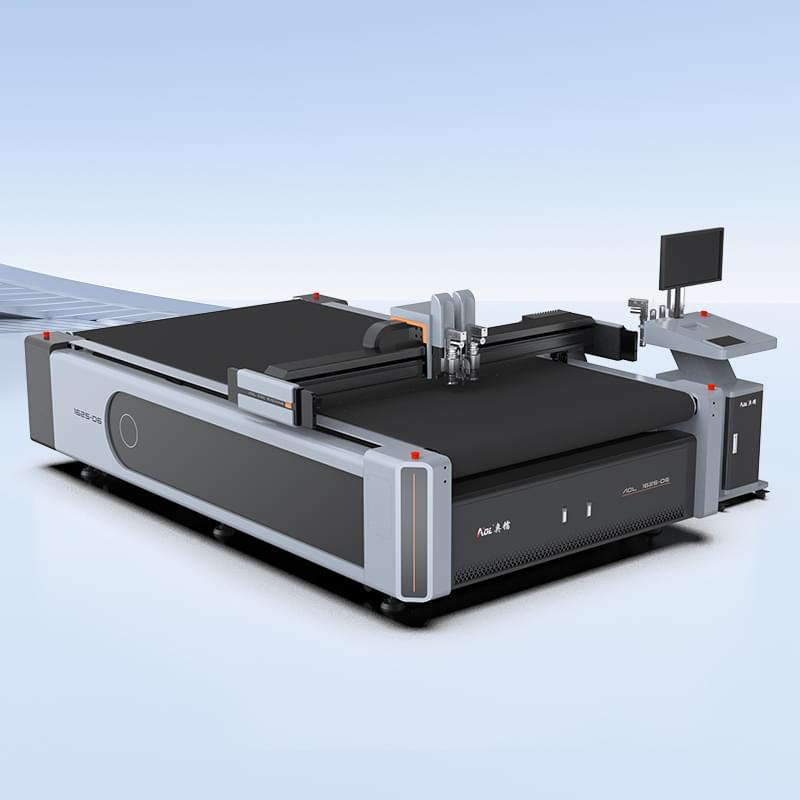

The CNC Automatic Rubber Leather Cloth Cutting Machine provides precision, speed, and versatility to cut complex 2D patterns in high volumes through automated digital tool path technology. Its die-cutting optimization capabilities make it a valuable production asset for sign manufacturers, printers, packaging companies, and other cutting and forming industries.

The cutting machine can cut a variety of materials, including foam, rubber, cardboard, leather, and more. The main component of the CNC Automatic Rubber Leather Cloth Cutting Machine is the cutting head, which consists of a blade that moves up and down as it cuts the material. The cutting head automatically adapts to the different heights of the material and can easily cut multiple layers at once.

Automatic rubber leather cloth cutting machine parameters:

| Technical parameters / model | AOL-1625 | AOL-1825 |

| Effective working area | 1600x2500mm | 1800x2500mm |

| Multi-function tool | Pneumatic knife, projector,vibrating knife,Round knife | |

| safety devices | Using infrared sensors, responsive, safe and reliable,Anti-collision system,Four corner emergency stop button | |

| Cutting speed | 300-2000mm/s | |

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |

| Applicable materials | Linen, polyester yarn-dyed knitted fabrics, chemical fiber fabrics, blended fabrics, Hong Kong knitted woolen fabrics, polyester knitted labor fabrics, viscose fiber, leather, acrylic fiber, mulberry silk, spandex, synthetic fiber, man-made fiber, corduroy and other textile fabrics | |

| Material fixing method | Vacuum partition adsorption | |

| Transmission port | Network port | |

| Transmission system | The XY axis is divided into two kinds of rack or belt | |

| rated power | 11kw | |

| Rated voltage | 380V±10%/220V±10% Optional | |

| Control System | Chinese and English LCD touch screen | |

| Operating environment | ||

| Support file format | AI、PLT、DXF、PDF、 PCE、XML | |

| Overall size | 3600*2400*1250 | 3600*2600*1250 |

CNC automatic rubber leather cloth cutting machines are designed using CAD (Computer Aided Design) software. This software is used to program the machine to make complex cuts and shapes that are impossible to achieve using manual methods. The software calculates the most efficient way to cut the material, ensuring minimal waste and maximum precision.

The benefits of CNC automatic rubber leather cloth cutting machines are many. First, they reduce labor and production costs by eliminating manual labor. Second, they increase accuracy and speed, which reduces lead times and increases production. Third, they are able to make complex cuts, which means that complex shapes and designs are possible.

All in all, CNC automatic rubber leather cloth cutting machines are game changers in the manufacturing industry. Their ability to cut materials quickly, accurately, and precisely makes them an important tool on the production line. These machines ensure efficient, effective manufacturing, reducing the need for manual labor, thereby reducing production costs. As technology continues to advance, CNC digital cutters will become more advanced and efficient, further revolutionizing the manufacturing industry.

Advantages of Automatic Rubber Leather Cloth Cutting Machine:

Have you ever wondered how some of the biggest brand companies are able to produce high-quality, precisely cut materials for their products? The answer lies in their use of digital cutters. These advanced machines are designed to cut materials with extreme precision, speed, and efficiency. But what exactly are the advantages of using a digital cutter over traditional cutting methods?

Precision Cutting

One of the biggest advantages of digital cutters is their precision. These machines use highly advanced technology to ensure that every cut is accurate and perfectly aligned. This is especially important when working with complex designs or patterns, as even the slightest deviation can ruin the final product. With a digital cutter, you can trust that every cut will be accurate and consistent, time and time again.

Faster Production Time

Another advantage of digital cutters is speed. Traditional cutting methods can be very time-consuming, especially when working with complex designs or large amounts of material. However, with a digital cutter, you can cut materials in a fraction of the time it would take with traditional methods. This means you can produce more products in less time, increasing productivity and profitability.

Reduce Waste

Digital cutters are also more efficient than traditional cutting methods when it comes to reducing waste. These machines use computer-controlled software to optimize cutting patterns and reduce the amount of material wasted. This means you can save on material costs and reduce your environmental impact by reducing the amount of waste you generate.

Wide Range of Materials

Digital cutters are versatile and can work with a wide range of materials, including foam, leather, rubber, fabric, and more. Traditional cutting methods may be limited in the types of materials they can cut, but digital cutter cutting machines are designed to handle the toughest materials with ease. This makes them ideal for companies looking to process a wide range of materials.

Enhanced Quality Control

Finally, digital cutter machines offer superior quality control. These machines are able to detect flaws in the material and make adjustments to ensure that each cut is precise and of the highest quality. This means you can produce products that are consistent in quality and appearance, and avoid costly mistakes or defects in the final product.

Digital cutters are a significant investment for any company, but their benefits far outweigh the cost. These machines offer a level of precision, efficiency, and quality control that traditional cutting methods can’t match. By investing in a digital cutter, you can increase productivity, reduce waste, and produce high-quality products that meet your customers’ demands. So if you want to take your business to the next level, consider investing in this cutting-edge technology.

AOL SERVICE

After sale service

Packing details of Automatic rubber leather cloth cutting machine

Transportation

Eight reasons to AOL CNC cutting machine

1. Advanced brand: Fourteen years of professional CNC blades

2. R & D advantages: a number of patented technologies, so that the company has a deep deposit

3. Quality assurance: all products have passed European CE certification. US FDA certification

4. High-quality materials: All CNC cutting machine accessories are selected from industry-leading brands.

5. Advanced technology: starting from Germany, foreign advanced technology, technical support

6. High efficiency: implement one-to-one service to improve the efficiency of corporate feedback

7. Personalized customization: With the development and design functions, customers can do whatever they want

8. After-sales service: provide three-year warranty service and 24-hour online solutions.

AOL company info

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.