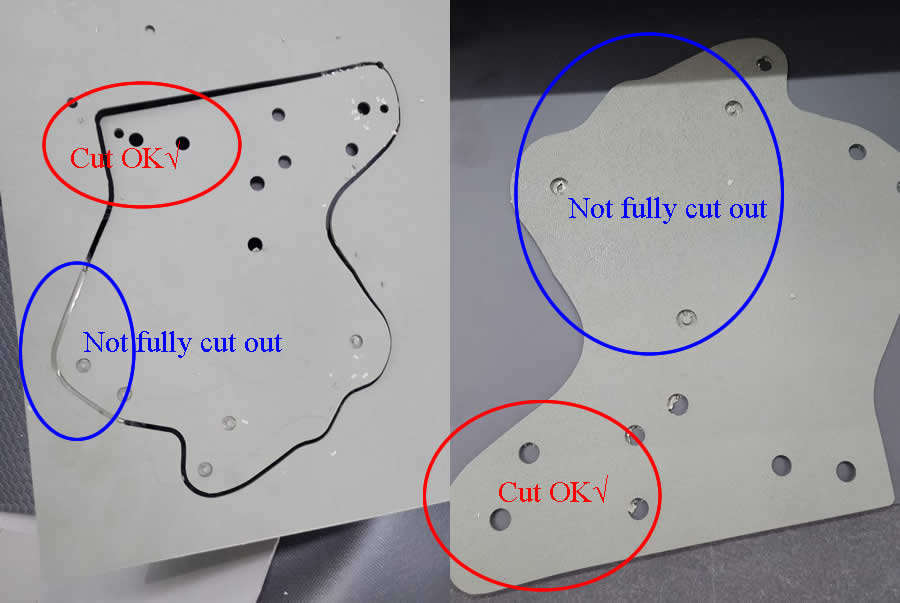

Why does your CNC cutting machine sometimes have uneven cutting?

The cutting effect is mainly affected by two factors:

1) Correct selection of cutting blades

We have a wide range of cutting blades suitable for cutting different materials. You can try several models or consult your machine supplier to find out which one is right for your material. In addition, pay attention to the state of the blade when cutting. If it is broken, replace it with a new one in time.

2) Flatness of the machine platform

The flatness of the machine table will be affected by two factors:

– Precision of machine aluminum platform

– Precision of cutting mat.

Some people use planar data loggers to record the table height and make certain changes to the cutter during the cutting process. Even so, there is still unavoidable bias between each collection point. That’s why cutting results vary from region to region.

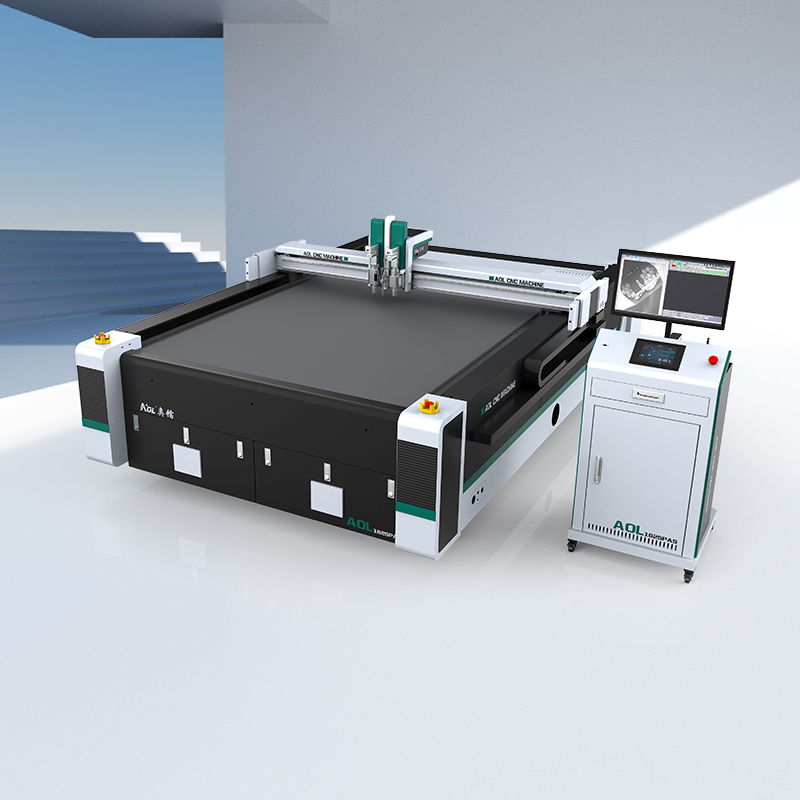

In view of the above-mentioned factors affecting the cutting effect, we recommend you to use AOL CNC vibrating knife cutting equipment. Our cutting equipment is welded with 6mm square tubes. After high-temperature heat treatment at about 800 degrees, the internal stress of the steel is released (to ensure that the equipment The accuracy will not change after long-term use), after natural cooling, the milling machine is finished, and the accuracy error of the bed is guaranteed to be within ±0.05mm. It can guarantee the cutting accuracy within ±0.1mm for a long time.

Get to know us in a video!

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/