If you are the owner of a sofa factory, do you often face three problems:

1.Clients are always proposing various changes to the size and design of the sofa.

2.Cutting sofas by hand is inefficient, resulting in long lead times.

3.Mass-produced standard sofas cannot be sold in time, which takes up a lot of money.

Traditional sofa production has the characteristics of single style and mass production, so many sofa factories choose multi-layer fabric cutting machines or manual multi-layer cutting methods to achieve efficient sofa production. As buyers pay more and more attention to the personalized selection of sofa style, color matching and size, the traditional sofa production mode can no longer meet the customized consumption needs of customers.

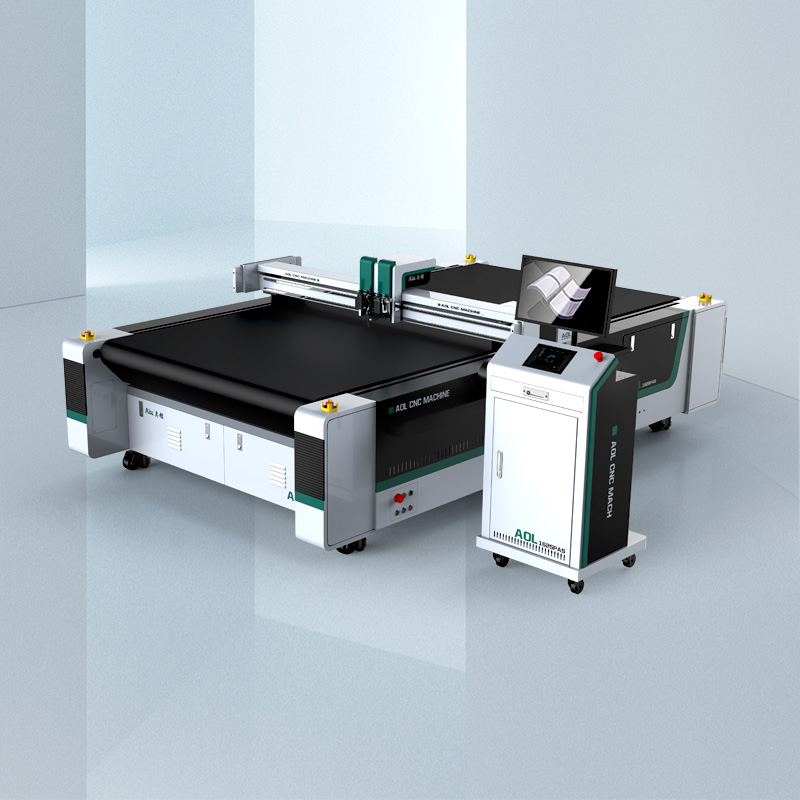

How to meet market demand and meet the “small batch, multi-style” order production is a problem that many sofa factories need to solve. AOL automatic sofa cutting machine integrates digital sofa parts management system, intelligent nesting system and automatic cutting system, helping sofa factories to establish a more intelligent, flexible and efficient cutting mode to meet the customized cutting needs of sofas. Each set of sofa can save 10% of sofa fabric.

Advantages of automatic sofa cutting machine:

1. Infrared sensor system, 360° surrounding safety, to ensure the safety of the operator.

2. Perfect camera positioning system, support ● or ten marks, etc., to improve work efficiency.

3. The solid aluminum honeycomb platform has good suction effect, ensures the platform is flat, and does not deform after long-term use.

4. Flexible tool system, compatible with all tools.

5. Efficient anti-dry roll feeding system, complete feeding and cutting within 5 seconds; enable the machine to realize automatic continuous cutting.

6. Powerful CAD editing and design software, perfectly matched with multiple software; and supports barcode reading, avoiding the operator from sending wrong cutting files and improving work efficiency.

7. The parameter setting system can adjust the best cutting parameters according to different materials to ensure the accuracy of each cutting.

8. The overall frame structure is designed by senior engineers in the industry, which is simple, stable, and easy to install and carry.

9. Precise knife setting system, easy to operate, can accurately control the depth of the knife and prolong the use time of the mat.

10. Scientific and concise wiring system and chassis circuit design, stable and safe; equipped with all tool interfaces to support subsequent upgrades; easy to install and maintain.

That’s all for the introduction of the automatic sofa CNC cutting machine. If you still want to know more, please visit our website https://aollaser.net/ or click to contact us, we will arrange professional personnel to recommend and answer!