Tent tarpaulin PVC coated fabric cutting machines are an indispensable tool for businesses and individuals involved in fabric processing and tent manufacturing. By understanding the different types, functions, and applications of these machines, you can make an informed decision that meets your specific cutting needs. Whether you need high-speed cutting, precision cutting, or specialized material compatibility, there is a tent tarpaulin cutting machine that can meet your needs. Embrace the power of precision cutting and open up endless possibilities in fabric design and production.

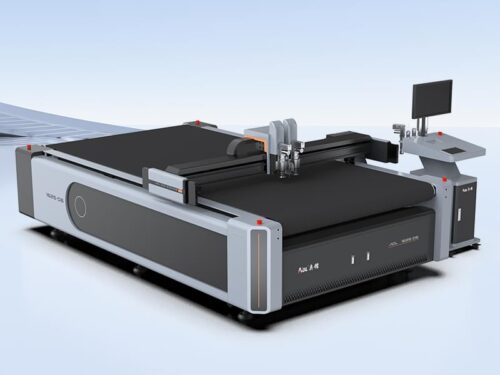

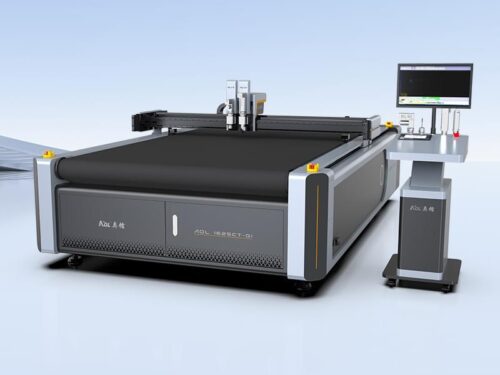

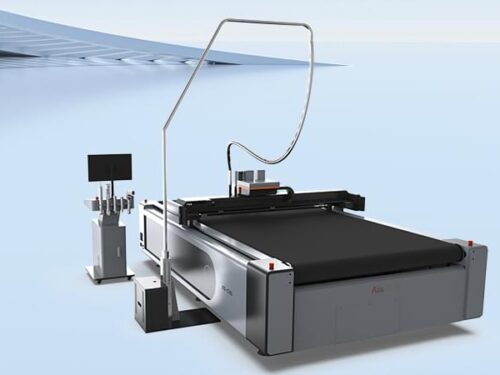

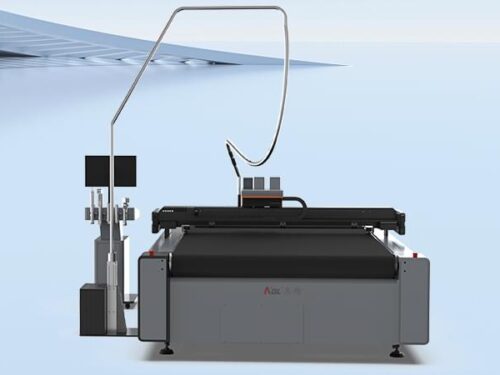

The tent tarpaulin PVC coated fabric cutting machine is an industrial equipment specially designed for efficient and accurate cutting of thick and flexible PVC coated fabrics. It is widely used in tents, advertising fabrics, truck tarpaulins, inflatable models, awnings, oilcloths, amusement equipment and industrial canvas. This equipment controls the movement of the tool through the CNC system to achieve automatic cutting, greatly improving the fabric processing efficiency and cutting accuracy.

Tent tarpaulin PVC coated cloth cutting machine technical data parameters:

| Technical parameters / model | AOL1625 | AOL1825 | AOL2125 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

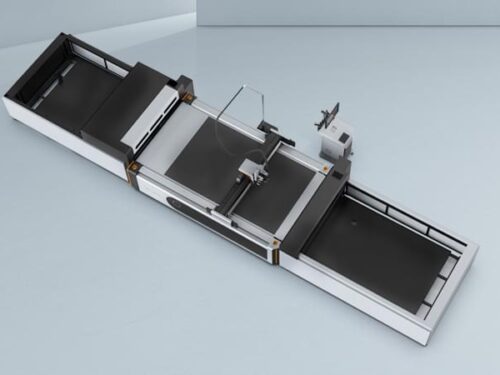

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | foam, vinyl, cardboard, paper, lable, fabric, gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

PVC coated cloth cutting machine related videos:

Our tarp cutting machines offer unmatched versatility and efficiency. Designed to adapt to your changing project needs, they feature a level of flexibility that will revolutionize your workflow.

Imagine switching seamlessly between different tools to handle different materials and complex designs. With our modular cutting machines, you can customize your settings so you can switch tools with ease. This adaptability means you can take on a variety of projects without the need for multiple dedicated machines, saving you time, space, and resources.

Whether you’re working with textiles, plastics, composites, or other materials, our modular cutting machines ensure you’re always equipped with the right tools. Embrace the future of cutting technology and experience the freedom to innovate, create, and transform with unparalleled precision and ease.

Advantages of tent tarpaulin PVC coated cloth cutting machine:

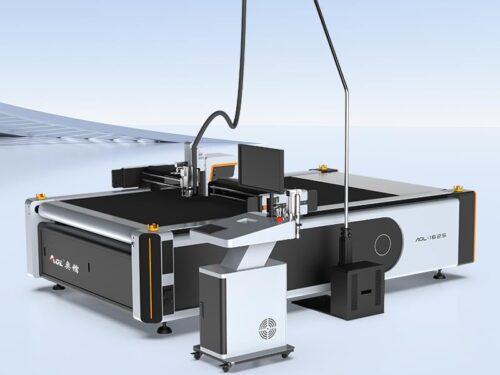

New modular tool holder design:

It is easier to install tools. When customers increase the product variety, they only need to purchase new required tools. It provides convenience for customers to upgrade their products. Compatible tools: rotary knife, marker pen, automatic feeder, etc.

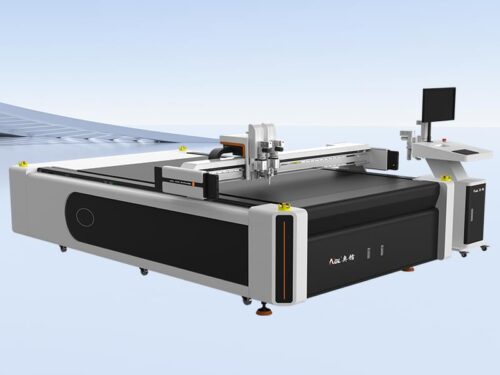

High-precision aviation aluminum table:

With the unique internal suction structure, it ensures that the suction force in each area of the platform is uniform and stronger.

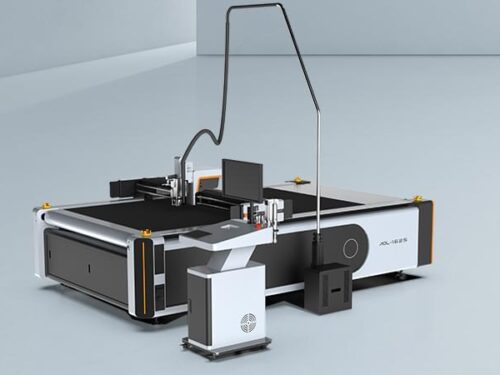

Infrared sensing safety device:

Adopts horizontal and vertical anti-collision protection to ensure no dead angle and effectively protect the safety of operators.

Pinion and rack:

The equipment adopts gear rack transmission. Compared with belt transmission, it has large load-bearing capacity, high transmission accuracy, fast transmission speed and long service life.

Distribution box:

The CNC cutting machine fixes the control electrical box on the machine body to avoid line failure caused by detachment. All lines use high-flexible cables with good wear resistance, moisture resistance, cold resistance and high temperature resistance.

Bed structure:

The whole machine adopts 6mm thick square tube, overall welding process, and imported milling machine processing, which ensures the flatness of the guide surface and rack surface, and greatly improves the stability of the machine body when the machine is running.

Felt:

High-density felt can provide good maintenance for the material, ensure each positioning fits tightly, and protect the flat plate when cutting.

Imported servo motor:

Stable performance, high precision, low failure rate, high speed performance.

Application scenarios:

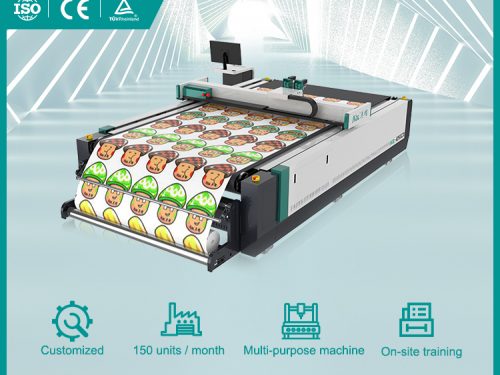

Tent manufacturers: can efficiently cut all kinds of outdoor tent fabrics to adapt to a variety of structural designs.

Advertising fabric processing factory: accurately cut large advertising spray-painted fabrics, light box fabrics, etc.

Car awning tarpaulin companies: suitable for large-scale processing of various truck tarpaulins and waterproof fabrics.

Inflatable mold equipment manufacturers: suitable for cutting inflatable molds, inflatable castles and other fabrics that require high-precision splicing.

Industrial protective fabric manufacturers: cutting wear-resistant and anti-corrosion industrial fabrics such as canvas and oilcloth.

Using a CNC digital cutter significantly simplifies the tarp cutting process, ensuring accuracy and consistency in the end result. Whether you’re making custom outdoor gear or handling industrial applications, this equipment can improve the efficiency and accuracy of your tarp cutting tasks.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.