I’m a garment manufacturer. I want to buy a garment fabric cutting tool. What kind of recommendation do you have?

When purchasing equipment, garment enterprises should first find out the production scope, processing materials and processing volume of their own enterprises,

So as to determine the model, format and quantity of equipment to be purchased, so as to pave the way for later procurement.

If necessary, you can consult the relevant professionals of the equipment company, or invite professionals to conduct on-site simulation solutions or provide solutions.

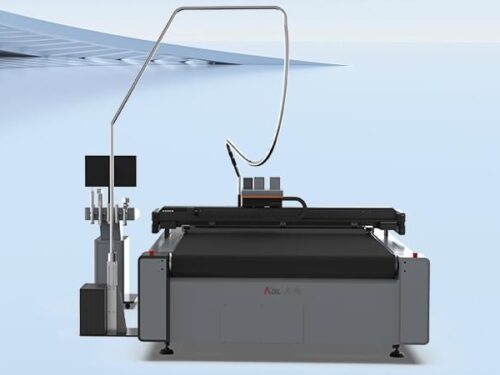

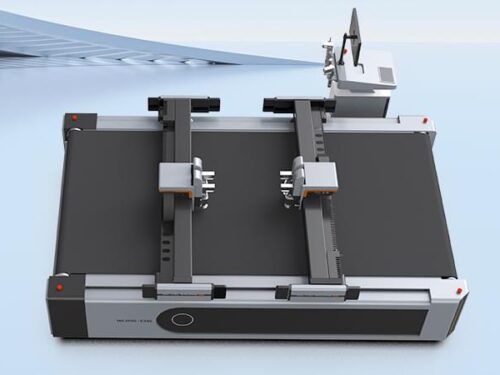

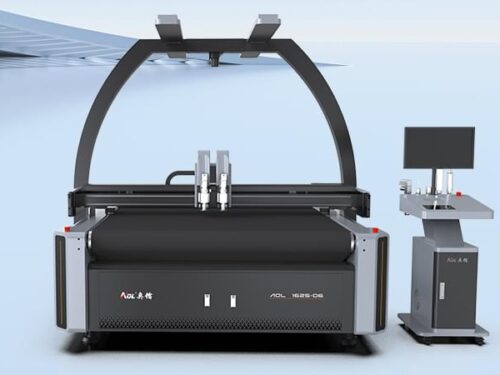

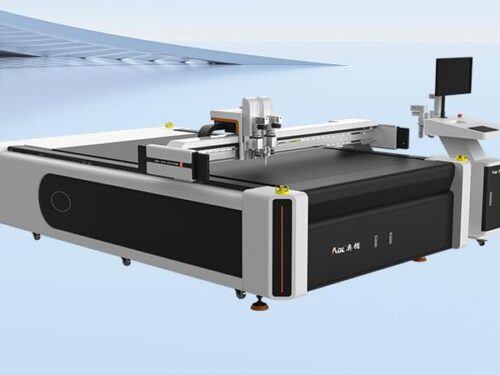

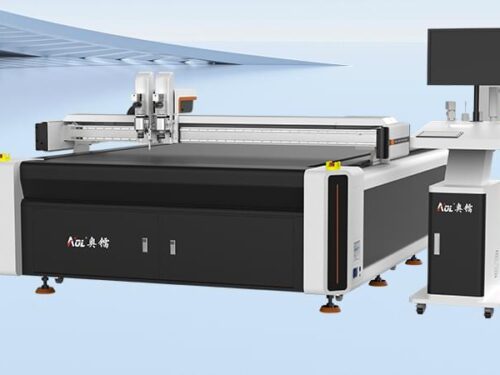

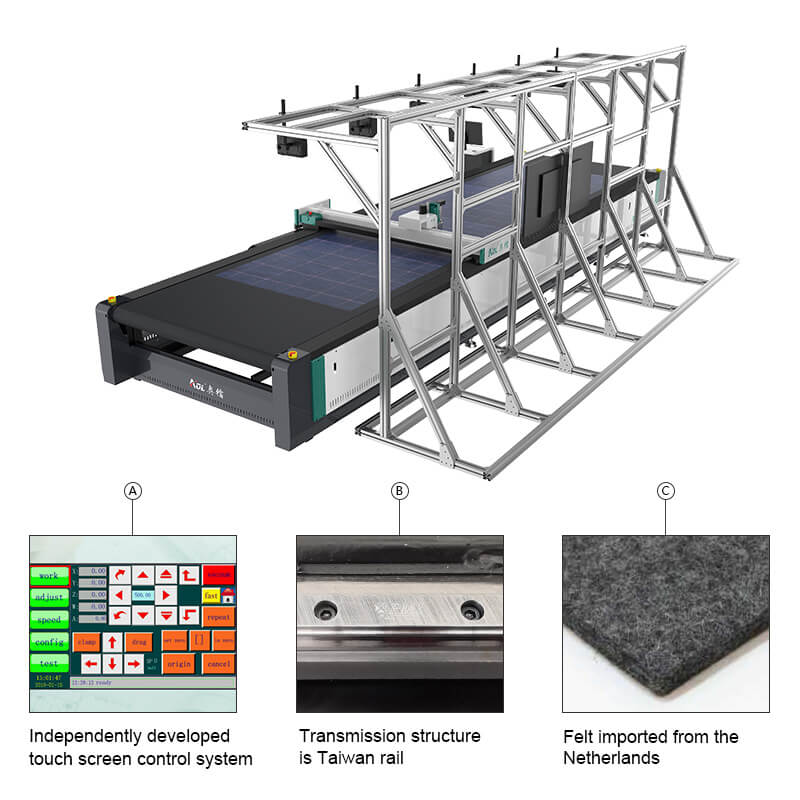

If a large enterprise needs an assembly line, it is recommended to choose an automatic fabric cutting machine.

With fully automatic digital fabric cutting machine, the efficiency is improved a lot.

The initial process of playing the board can be omitted. Employees only need to import the electronic template built in the early stage, and then send it directly to the super typesetting software.

AOL Super Master typesetting software can rank you to the highest utilization rate and maximize the use value of fabric cutting! Maximum material saving, high cutting accuracy and zero error, saving more than 10% on average compared with manual work. This function can help you improve the utilization rate of materials and reduce the cost of materials; In terms of cutting speed, one machine can replace about 5 workers.

It can also be used with the cloth paver to cut while feeding, which greatly improves the cutting efficiency.

Not advertising, using typesetting software is really powerful! But relatively speaking, oh! The utilization rate of some styles with complex structure is also very low!

In addition, some friends have considered choosing a laser cutting machine. Unless you have special requirements for the edge of materials, it is not recommended to choose a laser cutting machine, because the edge of laser cutting will be yellow and black, and some will become hard.

What kind of cutting machine should small manufacturers choose for mass production of clothing

If the requirements for convective water line operation are not high, choose electric scissors. The electric scissors used for cloth cutting include straight knife and machete. If it is not special cloth, it is recommended to choose straight knife. The cutting efficiency of electric scissors is relatively high. It can cut tens of centimeters at a time, but it needs manual work. Pay special attention when using, because many workers have been hurt by electric scissors.

What cutting tools should be selected for personal studio and small batch production

If you want to make a pattern for personal clothes, you can buy a manual scissors or a small electric scissors. Because the workload is small, there is no need for mass production.

When making paper patterns, some people often do three-dimensional cutting on the people’s table to determine the shape and size of the cutting pieces. Therefore, people with cutting foundation can prepare a cutting people’s table, which should have tools such as embryo cloth, scissors, bead needle and big pen.

I hope I can help you. Select AOL to make cutting easier.

If you have other questions, please consult online!