“I’m doing car interiors, and I want to know the difference between a vibrating knife cutting machine and a rotary knife. The rotary knife I used before was not good, and then I used a laser. The smell is too strong and it is easy to damage the material. Recently, it is environmentally friendly. Check, don’t use it, I saw your post about the vibrating knife cutting machine, and I want to know more about it.”

This is what a friend who is doing car interiors sent me a private message, and the problem has now been solved for him. Today I want to take it out separately because I found that many people will encounter such similar problems, not only those who make car interiors and floor mats, but also many manufacturers of flexible materials, so I will tell you about it. The reasons for this may be a turning point for everyone.

Let’s take car seat cushions and floor mats as an example. The rapid development of the automobile industry and the increase in demand have led to the development of the subsidiary industries of the automobile industry, and the automobile interior is one of them. With the growth of time, more and more people are working in this industry. Some people are doing well, and some are unable to do anything. It seems that they have reached a bottleneck and their development has become slower. At this time, the emergence of cutting equipment made it prosperous again.

In terms of flexible materials, the development of cutting machines is from the three stages of rotary knife – laser – vibrating knife.

Below I will take you to know them from the working principle:

Old-fashioned rotary knife cutting machine: Cut fabrics and leather materials through high-speed rotation of the cutter head, and drive it to complete a system action through software to meet customer requirements. The advantage is that the price is relatively cheap, but there are also certain disadvantages. On the one hand, there are two pressing rods, and the material is pressed by the pressing rods. Because the material is thick when the pressing rods operate back and forth, it will lead to the cut out of the sample. , there will be errors. For example, the pattern of 1.0 meters will become larger by 2-4 cm; on the other hand, in the early three months of use, the cut edge looks OK, but it is jagged and will produce a lot of broken pieces. The crumbs are not good for the operator’s health, and it is not easy to clean up. three months later. Due to the wear of the nose part in the early stage, the cutting surface is scribbled in the later stage, it is difficult to sew, and it is difficult to control the quality.

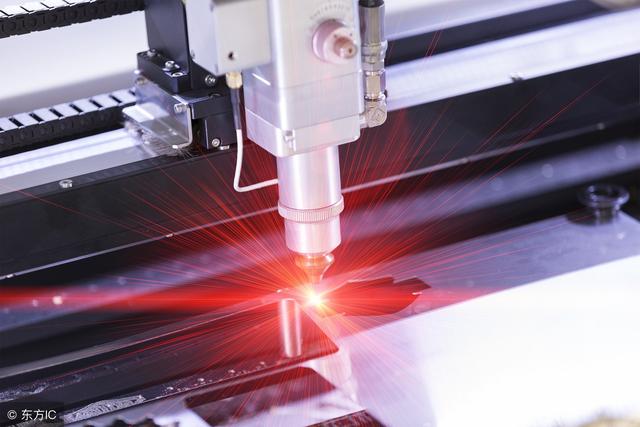

Laser cutting machine: In cutting flexible materials. Compared with the rotary knife, the cutting surface is very good, clean and smooth, but the maintenance of the laser machine is also more. The laser head will heat up for a long time and needs water cooling. The main reason is that the laser cutting machine completes the cutting through high temperature, so after cutting the fabric, there is a high chance of leaving a yellow mark. Another disadvantage is that the smell is very strong. Environmental protection departments in many places will check it in three or two days and basically do not allow it to be used. Therefore, many factories are no longer using it.

Vibrating knife cutting machine: The principle of the vibrating knife is to use the blade to vibrate up and down to cut, and vibrate tens of thousands of times per minute, which is similar to the principle of the saw blade, but there is no sawtooth and no powder is generated. Materials, you can choose round knives, half cutters, drag knives, bevel knives, milling knives, etc. The finished products cut by the vibrating knives are also clean and neat, with smooth edges, and the size of the pieces is accurate, odorless, environmentally friendly, soft, All hard materials are used, and the leather modification system of the foot cushion and seat cushion is well used.

At the same time, its cutting speed is twice that of a rotary knife and twice that of a laser. It is also the first choice of many companies now.

Through the description of the above three kinds of cutting equipment, everyone should be able to understand, especially friends who have used one of them, will know very well.

On the vibrating knife cutting machine, AOL has increased its performance, making it more intelligent, accurate and comprehensive, so that it can help you solve more cutting problems. Let’s take a look at it together!

1. The speed is increased. The cutting speed of the vibrating knife is as high as 2000mm/s, which can maximize the production volume. One cutting machine is equivalent to 4 to 6 workers.

2. The improvement of precision, the precision of the material cut by the vibrating knife cutting machine is 0.01mm, which can maximize the precision of the product, improve the quality and competitiveness of the product.

3. The improvement of intelligence, the vibrating knife cutting machine can automatically cut only by inputting the graphics to be cut in the computer, without manual guarding and regulation.

4. For the improvement of freedom, you can choose CCD camera, projector, double cutter head, double gantry, lengthen and widen the working area of the cutting machine, etc., tailor-made according to your own needs.

Well, I will tell you so much today. If you want to know more about it, you can read other articles on the website, or if you want to make an inquiry or ask for details, please contact us, and we will have professional staff for you in detail. ‘s answer!