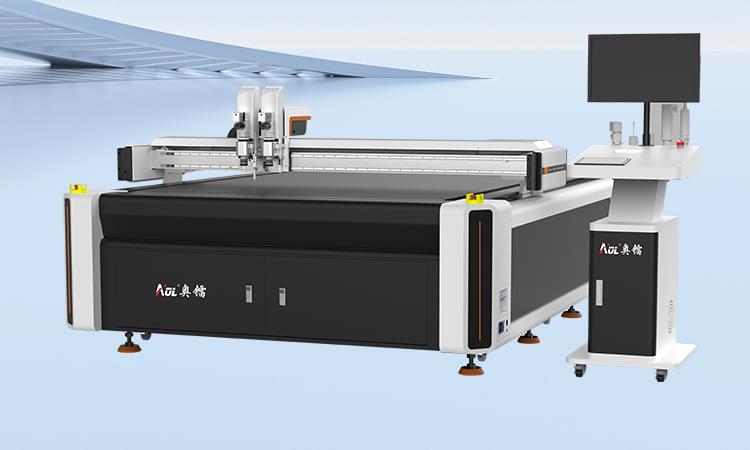

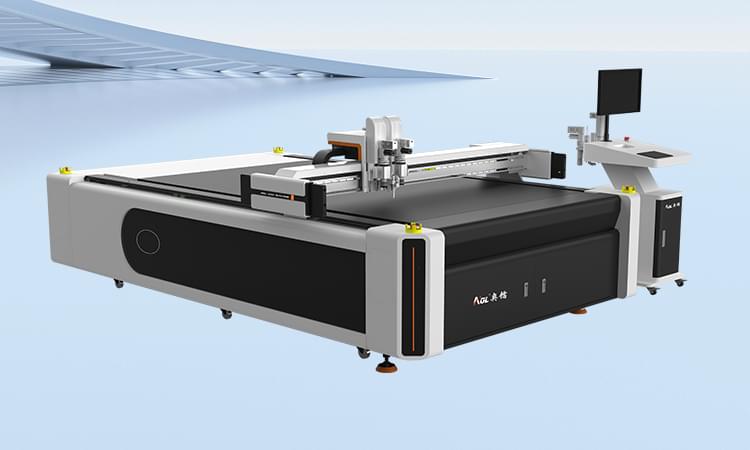

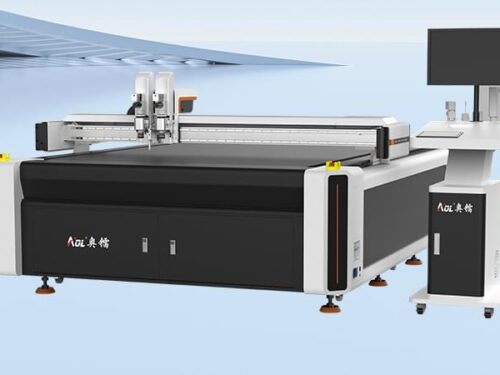

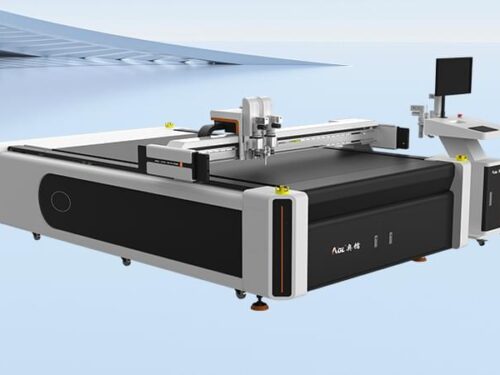

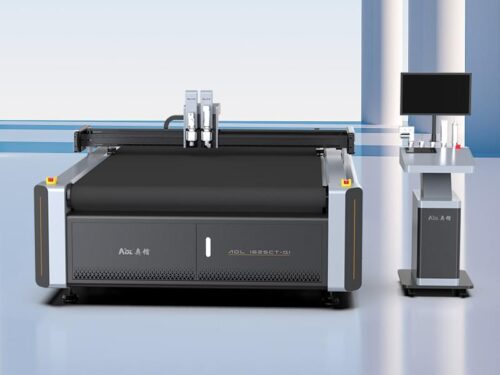

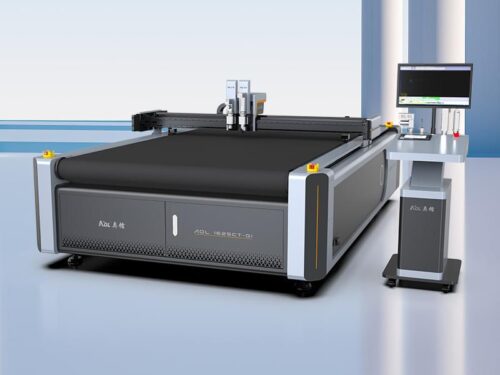

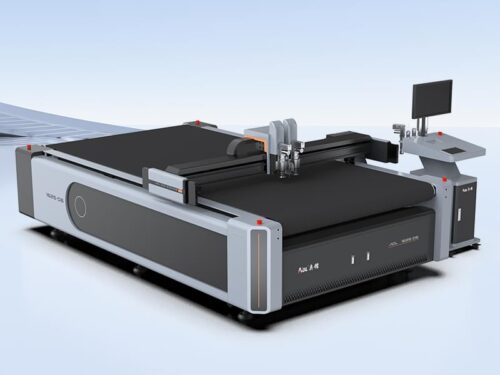

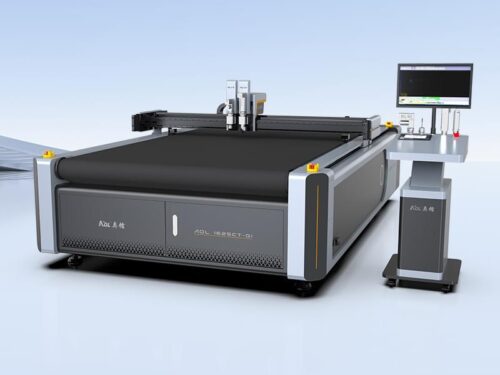

In the competitive landscape of modern industry, efficiency and precision are of paramount importance. Although often overlooked, washers play a vital role in the functionality and safety of countless machines and equipment. AOL CNC is a leader in innovative cutting solutions and its vibrating knife washer cutting machine is revolutionizing the washer manufacturing industry.

Gaskets are integrated components that provide a sealing solution between two surfaces, preventing the leakage of liquids or gases. They are indispensable in various industries such as automotive, aerospace, oil and gas, and manufacturing. The performance and reliability of machinery often depends on the quality and precision of the gaskets used.

What is a CNC gasket cutting machine?

CNC gasket cutting machine is an automated equipment that uses computer control technology to cut materials. Through pre-programming, CNC cutting machine can accurately cut according to the requirements of design drawings, suitable for gasket processing of various complex shapes and high precision requirements.

Parameters of CNC gasket cutting machine:

| TECHNICAL PARAMETERS / MODEL | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | ACCEPTING SPECIAL-SHAPED CUSTOMIZATION |

|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500mm | |

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, semi-cutting cutting, full cutting cutting, camera positioning cutting, edge finding cutting, acrylic milling cutter, cursor positioning, line marking, indentation knife, V-groove knife, etc. | |||

| safety devices | Infrared sensing, safe and reliable | |||

| Cutting speed | 200-2000mm/s | |||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||

| Applicable materials | Various KT boards, Chevron boards, honeycomb boards, car stickers, adhesives, photo frame paper, gray board paper, corrugated paper, EPE foam, PVC board, acrylic sheet, thick foam, etc. | |||

| Material fixing method | Vacuum partition adsorption | |||

| Transmission port | Network port | |||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||

| rated power | 11kw | |||

| Rated voltage | 380V±10%/220V±10%Optional | |||

| Control System | Chinese and English LCD touch screen | |||

| Operating environment | Temperature 0-40°C Humidity 20%-80%RH | |||

| software | Automatic nesting software, camera positioning, large format camera system | |||

| Support file format | AI、PLT、DXF、CDR etc. | |||

Advantages of CNC gasket cutting machine:

1. Unparalleled Precision and Accuracy

AOL CNC’s machines utilize advanced CNC (Computer Numerical Control) technology to provide unparalleled precision. The oscillating knife mechanism ensures clean, smooth cuts, faithfully reproducing the most complex gasket designs with precise accuracy.

2. Improved Productivity

Significantly increased production speed. The high-frequency oscillating knife can quickly cut materials without sacrificing quality, allowing manufacturers to meet tight deadlines and increase production.

3. Improved Material Utilization

Intelligent nesting software can arrange gasket patterns to minimize waste, reduce material costs and promote sustainable manufacturing practices.

4. High Safety

CNC cutting equipment is equipped with multiple safety protection devices, such as emergency stop buttons, protective covers, etc., to ensure the safety of operators.

What should we pay attention to when maintaining the equipment?

1. Regular cleaning: Keep the inside and outside of the equipment clean to prevent dust and debris from affecting the performance of the equipment

2. Lubrication and maintenance: Lubricate the moving parts regularly to extend the service life.

3. Check wear: Regularly check the wear of the tools and other wearing parts and replace them in time.

4. Software update: Regularly update the control system software to obtain the latest functions and fix potential problems

With its high precision, high efficiency and versatility, CNC gasket cutting machine provides strong support for the transformation and upgrading of the gasket industry. Whether you want to improve product quality, increase production efficiency, or expand new market opportunities, CNC cutting equipment is your ideal choice. If you have any questions or need further information, please feel free to contact us, we will provide you with professional solutions and support.

Reviews

There are no reviews yet.