Self-adhesive quality inspection is an important task. Before printing and processing, it is necessary to carefully check the appearance quality of self-adhesive materials, so that defects that may cause printing processing quality problems can be found in time before printing. AOL has been engaged in the production and research and development of self-adhesive cutting machines for many years, and has deeply researched its quality. We will explain how to carry out effective quality inspection:

1. Check whether the self-adhesive material has burrs

Before printing and processing, be sure to carefully check whether there are burrs on the cutting edge of the roll self-adhesive material, and whether it is caused by storage and transportation. This is an important part.

2. Check the adhesive material for cracks

When the self-adhesive material is cut, if the knife is not adjusted properly or the blade is not sharp enough, cracks will appear in the face or backing paper of the self-adhesive material, and the fibers pulled out from the cracks will be bonded by the adhesive. Therefore, there is no need to double-check the backing paper before printing self-adhesive materials on the machine. Check the paper for small cracks.

3. Check whether the edge of the self-adhesive material is attached and whether the backing paper lacks silicon coating

The edge of the self-adhesive material is stuck or the silicone oil leaks from the bottom paper, which will cause the surface paper to break during the printing process and cannot be produced normally. Therefore, before printing, take a piece of self-adhesive material about 1 meter long and tear it off by hand to see if there is any part that cannot be peeled off smoothly and evenly on the edge or other parts.

4. Check whether the cutting end face of the self-adhesive roll is straight and whether the winding elasticity is consistent

If the slitting end face of the roll self-adhesive material is not uniform, it will not only affect the registration during printing, but also cause waste disposal difficulties due to the change of the die-cutting position; inconsistent tension during winding will lead to paper tension during printing. Variation and uneven tension can also cause print quality issues.

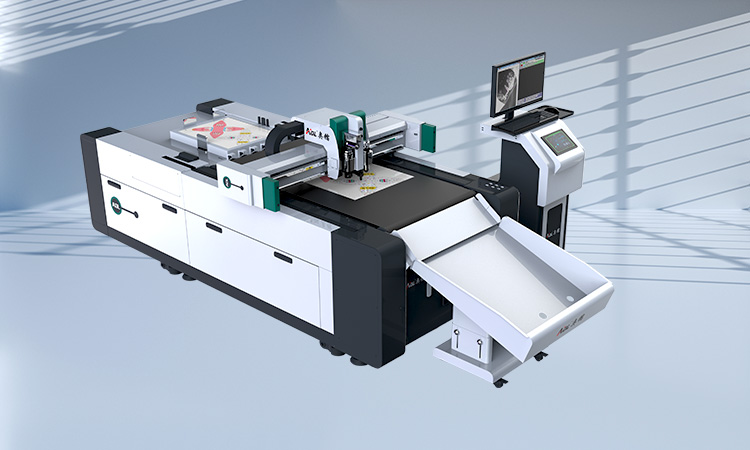

Function introduction of self-adhesive cutting machine:

1.AOL self-adhesive cutter automatic intelligent cutting system adopts fully automatic vacuum chuck and automatic lifting and feeding platform.

2.Equipped with different tools. Oscillating knife cutting tool, drag knife cutting tool, V cut, crease wheel,cut-through-knife,marking pen and CCD camera. It also have pneumatic knife cutting tool, round knife cutting tool and feed roller for optional. Realize different types of material cutting.

3.It can quickly and precisely make through cutting,half cutting,creasing and marking.

4..Besides, the machine has CCD camrea, which highly improve cutting accuracy, It is a cost-effective smart equipment that meets all your creative processing.

5.AOL self-adhesive cutting machine is widely used in packaging and signs, including, paper, board, sticker, vinyl and so on. It is the key equipment for small volume production and sample making.

6.This machine provides perfect solutions for printing.

Through the inspection of these key factors, the quality of the self-adhesive can be well controlled. I hope it will be helpful to everyone. If you need to consult the problems in the cutting process or want to consult the relevant information of the self-adhesive cutting machine, please contact us , we will answer you as soon as possible!