Rubber sealing washer is a kind of sealing spare parts used in machinery, equipment and pipelines as long as there is fluid. It uses internal and external materials for sealing. Widely used in medicine, electronics, chemical industry, antistatic, flame retardant, food and other industries.

It is made of metal or non-metal plate material by cutting, punching or cutting and other processes.

According to the material, it can be divided into metal gaskets and non-metal gaskets.

Like metal, there are copper gaskets, stainless steel gaskets, iron gaskets, aluminum gaskets, etc.

Non-metallic asbestos gaskets, non-asbestos gaskets, paper gaskets, rubber gaskets, etc.

Rubber gaskets are widely used and one of the indispensable spare parts, so the demand and market are still very objective.

What we are going to discuss with you today is the cutting and cutting of rubber gaskets, and understand how the rubber washer cutting machine brings us value. (This article uses non-metallic washers as an example)

Let’s talk about manual cutting of rubber gaskets (punch).

The punching machine is used very frequently in the cutting of rubber gaskets, but using the punching machine will encounter some problems, such as the problem of the mold, one style needs a mold, and the accumulation of the mold not only takes up space, but also costs a lot of money, such as small batch customization , it is even more inconvenient, which greatly limits the development speed.

Then there is the waste of materials. A good puncher will give you a way to save materials and reduce waste, but how many such workers can there be? The number of pieces determines his income. In many cases, he doesn’t care whether you waste materials or not. Anyway, I made the quantity for you, and the cost issue has nothing to do with me. How can I explain this phenomenon? It’s hard to control, you can’t stare at it every day, it’s too tiring.

It is becoming more and more difficult to find workers, the labor price of workers is increasing, the overall cost is increasing, profits are continuously decreasing, and the competitiveness of products is also declining. The consequences can be imagined.

It’s not that the punch press is not desirable, it’s just that with the development, it is no longer the best choice. Only by keeping up with the pace can we survive, and the backward will be eliminated.

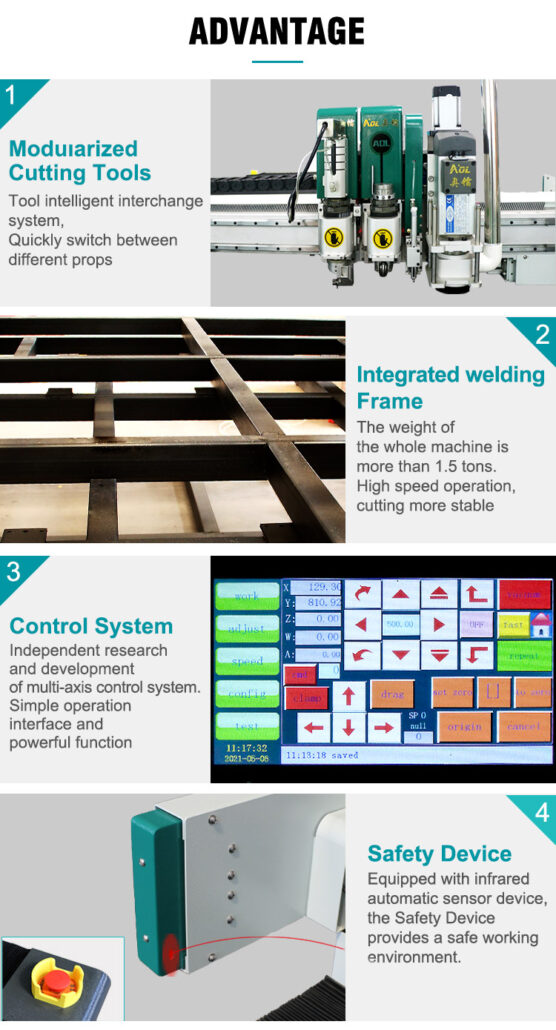

Next, let’s talk about the rubber washer cutting machine and some changes brought to us by automation equipment, taking AOL as an example.

The rubber washer automatic cutting machine does not need to punch the plate, only need to import the data into the system, you can identify and cut the material. The automation of this step directly saves a lot of time and cost.

The super nesting software is supplemented to complete the typesetting intelligently and accurately, without manual nesting. After a lot of tests, using the automatic cutting machine saves more than 10% of materials than manual labor. You can use this data to calculate how much you can save in a year.

The cutting is more accurate. The sealing gasket has high requirements in this regard. If there is an error, it will not match, which affects many aspects. In the process of cutting, the manual punch has a higher probability of deviation, and the machine passes through the software system. , which can minimize the error.

The machine is intelligent and automated, the operation is very simple, the number of workers required is small, and it can work continuously for 24 hours, getting rid of the problems of high labor cost and difficult recruitment.

The above are some comparisons between our manual and automatic cutting machines. You can contact us for specific materials. AOL makes cutting easier. I look forward to meeting you! Let’s move forward together on the road in the future, remember to click for details!

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/