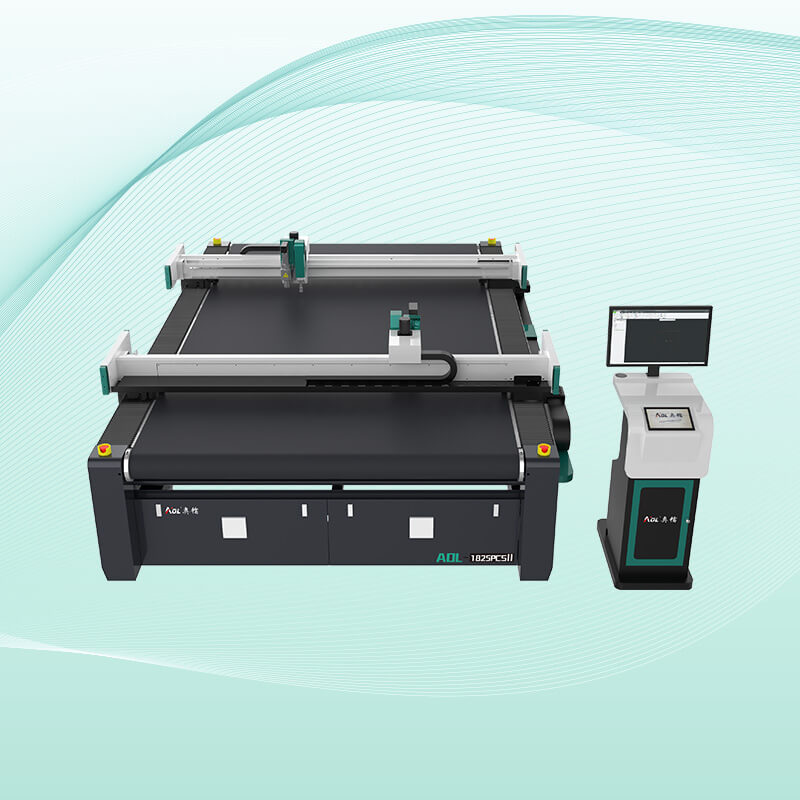

Honeycomb panel cutting machine is a special automatic equipment specially used for box-type proofing design of various honeycomb paper, carton, color box, plastic box and so on. Its function is to produce high-quality samples and some small batches of order production automatically, quickly, and without the need for molds. Saving proofing costs is also a necessary product for the development trend of printing and packaging plants. In addition to cutting various honeycomb panels, the machine can also cut leather, fabric, gaskets and rubber products.

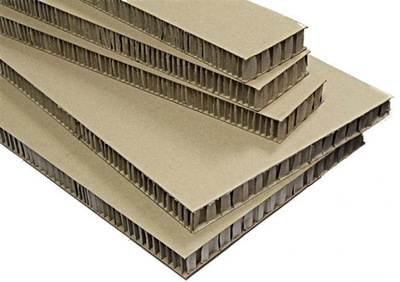

Honeycomb panel is a board made of two thinner panels firmly bonded on both sides of a thicker honeycomb core material, also known as honeycomb sandwich structure. In addition, the honeycomb panel also refers to a panel that welds a large number of cut-off waveguides together to form a cut-off waveguide array, forming a large opening area and preventing electromagnetic waves from leaking.

Honeycomb panels can be used to make all kinds of trays, liners, packaging boards, packaging boxes, etc. Paper honeycomb panel is a new type of green packaging material emerging in developed countries this year that saves resources, protects the ecological environment, and has low cost. It has many advantages such as lightness, strength, stability, heat preservation, heat insulation, and shock resistance.

The honeycomb panel cutting machine can be equipped with four cutter heads: vibrating cutter cutting head, creasing line wheel, V-shaped cutting head and high-speed milling cutter head. Honeycomb board cutting machine can cut or 50mm honeycomb cardboard, acrylic board, corrugated paper, plastic corrugated board, gray board paper, white cardboard, film, composite material, leather, cloth, rubber board, pearl cotton, aluminum-plastic board and foam KT board and other materials.

Features of honeycomb panel cutting machine:

1. The table compensation function is used to detect the flatness of the table through a high-precision distance detector, and to correct the plane in real time through the software to achieve a perfect cutting effect.

2. Vacuum adsorption function, super strong wind, strong suction, and the size of vacuum adsorption area can be selected, which greatly reduces power consumption.

3. Automatic tool setting function, fast and simple automatic tool setting system, using optical sensor to accurately detect the tool, greatly improving the tool setting efficiency.

4. High-definition CCD camera, realizes automatic positioning and sleeve cutting of various materials, and eliminates problems such as inaccurate manual positioning and printing deformation.

5. Double-head automatic switching function, the cutting process realizes the automatic switching of double-heads to meet the needs of different processing techniques of materials.

6. Overcut optimization function, using self-developed CAM software to systematically optimize the physical overcut phenomenon of the tool, restore the graphic outline to the greatest extent, and bring customers the perfect cutting effect.

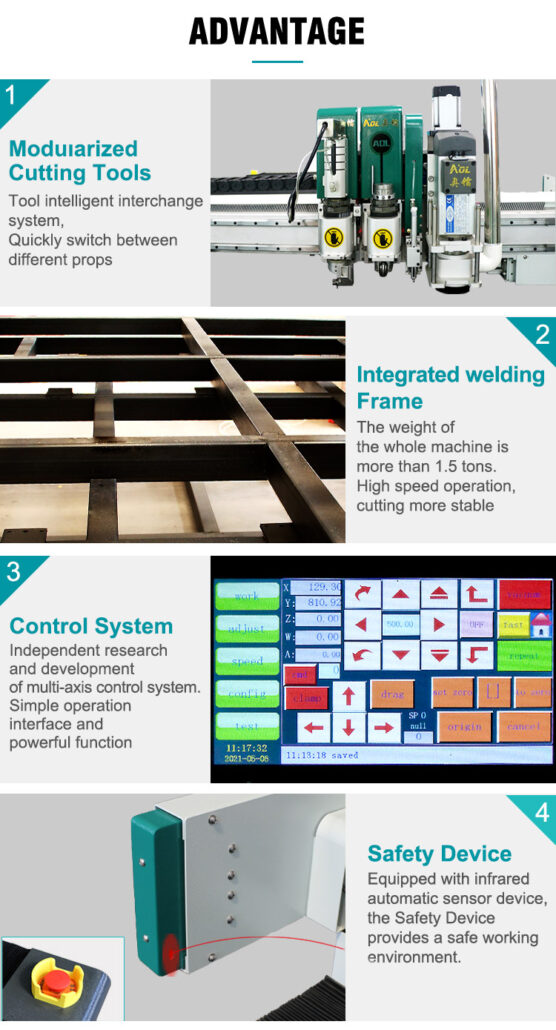

Advantages of honeycomb panel cutting machine:

1. The V-shaped cutting system can cut V-shaped grooves with 5 different angles, such as 45°, 30°, 22.5°, 15°, 0°.

2. Line drawing, text annotation, indentation, half-knife cutting, full-knife cutting, and bevel cutting is completed at one time.

3. Equipped with a conveyor belt, it can be continuously cut to achieve seamless production goals that meet the needs of small batches, multiple orders and multiple styles.

4. The multi-axis motion system adopts imported linear guides and servo motors to ensure that the cutting accuracy fully reaches the zero error of the round-trip origin.

5. The four directions of the fuselage are equipped with emergency stop devices and safety infrared sensing devices to meet the consideration of equipment safety at home and abroad.

6. Honeycomb panel cutting machine has a set of advanced and quick-change knives with unparalleled diversity. According to the needs of various processing materials, it is simple and fast to configure different cutter heads.

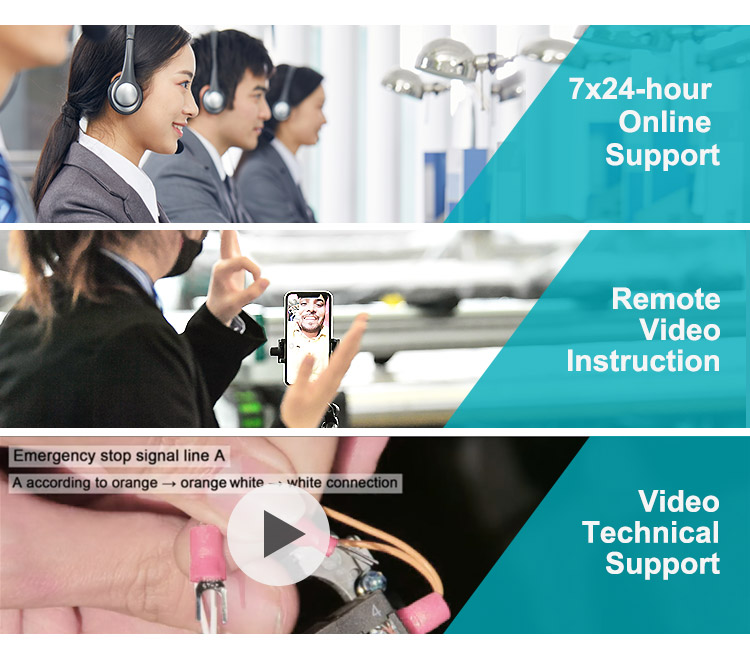

AOL Services:

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOL accepts unreasonable returns within 7 days after receiving the goods.

If you have any questions or want to know more, please contact us!

About the warranty policy:

Our standard warranty period begins when delivery is complete. We provide you with a three-year warranty service and provide professional machine maintenance

Renewal maintenance of machine parts is sold to customers at the lowest price.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/