Among the rubber products processed by rubber processing manufacturers, in addition to the common elastic soft rubber, it is a relatively special hard rubber product. However, how to cut hard rubber products better and faster has always been a headache for rubber processing manufacturers.

This article will bring you some confusion, you may wish to collect it before reading it, just in case you need it!

1. What is hard rubber products

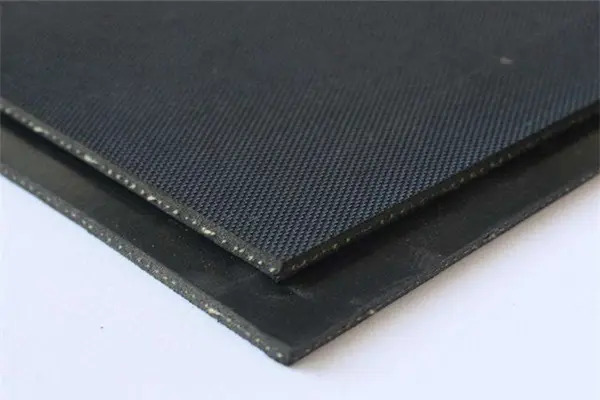

We call the rubber whose glass transition temperature is above room temperature and can hardly stretch as hard rubber, which is obtained by adding a large amount of sulfur to NR or SR and vulcanizing it for a long time. It is often used to make electrical insulation products, chemical equipment linings, and transition layers for rubber and metal bonding.

2. What are the common hard rubber products

In daily life, common hard rubbers include: rubber sealing products, rubber shock absorption products, hard rubber, rubber sponge products, rubber sheets and coils, rubber rollers and blankets, textile rubber products, printing rubber products, Rubber lining, rubber electrical insulation products, asbestos and cork rubber, rubber adhesives, rubber sealants.

3. How to better cut hard rubber products

As all manufacturers know, the operation method of rubber products is relatively strict, not only the working temperature must be above the glass transition temperature (then it will lose high elasticity), but more importantly, the special-shaped cutting process of hard rubber, and investment Production and sales.

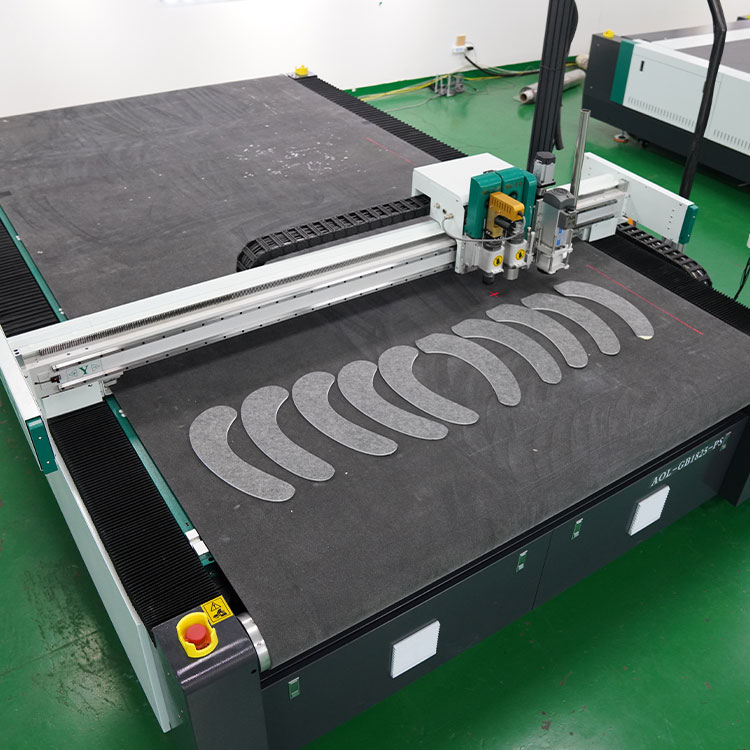

Due to the material specificity of hard rubber, manual cutting will be more complicated, and it will also result in labor and material consumption. On this basis, intelligent cutting equipment came into being, especially automatic blade cutting and processing equipment, which was favored by hard rubber cutting and processing manufacturers and put them into production and processing.

Rubber intelligent cutting equipment belongs to industrial production equipment and has three main functions. The first is to improve work efficiency, the second is to reduce labor costs, and the third is to solve the problem of complex graphics cutting. At present, one rubber intelligent cutting equipment can replace multiple labors, saving a lot of money for the factory, improving the production capacity of the enterprise and the quality of finished products.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/