CNC vibrating knife cutting is a relatively widely used processing equipment in the cutting process of flexible materials. It uses the upper and lower high-frequency vibration of the blade for cutting. It has high precision, fast cutting speed, and is not limited to cutting patterns. It can be automatically cut. With the characteristics of loading and unloading, intelligent typesetting, and low cost of smooth incision processing, the traditional flexible cutting process equipment is gradually improved or replaced. So what are its uses?

In the production and processing of automotive interior products, the vibrating knife cutting machine can cut them just right according to the different models. It is suitable for car mats, trunk mats, leather covers, seat covers, cushions and other materials, which greatly increases the efficiency of work and reduces labor costs. For the advertising/packaging industry, it can quickly locate and identify, automatically find and cut edges, and greatly reduce the workload of operators. It is suitable for cutting and production of KT board, Chevron board, self-adhesive, corrugated honeycomb board and other materials.

For branded clothing, high -end clothing cuts and cut, and research and development of high -power cutting heads. The tailoring of clothing is fast. The tailoring fabric is not dragged on water, and there will be no shredded condition. Prepare different blades for different clothes, and the corners are more flexible.

In the processing technology of composite materials, the vibrating knife replaces the manual drawing and cutting process in the traditional composite product production process, especially for the cutting of complex samples such as special-shaped and irregular patterns, which greatly improves the production efficiency and material quality. utilization. Vibrating knives are used in a wide range of industries. Of course, there are more than the categories mentioned above. Of course, if you want to use the vibrating knife to cut your product, you must also remember to take the material for proofing before purchasing, so as to understand the cutting effect more effectively.

How to choose a cost-effective vibrating knife cutting machine?

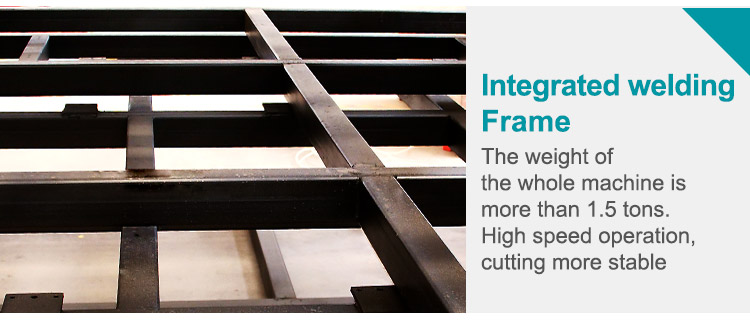

Look at the quality of the vibration knife cutting machine. From the perspective of the appearance, a good vibration knife cutting machine can be separated from the different levels of vibration knife cutting machine. The general rules of the processing equipment follow the better quality, the heavier the weight, because the weight is because The better the quality, the thicker the material needs. Of course, when we buy the vibration knife cutting machine, there is no way to call it, but it is still possible to ask the manufacturer to obtain the quality of the vibration knife cutting machine and the quality of the vibration knife cutting machine It also reflects the use of poor quality of vibration knife cutting machines in the service life for half a year. After half a year, it will show a sensation in the fuselage. The vibration knife cutting machine can be operated normally for two or three years, and it can be continuously used only for fundamental protection.

Choose according to the thickness and precision of the material you are cutting. Now most equipment companies can provide the service of trial cutting samples. You can ask them to cut your materials. If the cutting is satisfactory and the precision is high, it can be used as the key equipment. Of course, under the trend of the general environment, many foreign friends If you can’t come to our factory to visit and cut samples, you can send us the material and tell us the cutting pattern, our technicians will cut the sample according to the requirements and record the whole cutting process for sending.

If there is no problem with the above mentioned, the last thing you need to know is the performance of the equipment, the technical support that can be provided and whether the after-sales service is comprehensive. There are agents and service sites in the place, and there are old customers in many places. If the old customers are convenient, they can go to visit and consult the usage. I believe that the real experience of customers is the most impressing customers.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/