In the advertising packaging industry, there is a type of cutting machine that is generally accepted by users. CNC cutting machines —cutting cutters. This machine has the basic functions of designing and cutting in the advertising packaging industry, and also has powerful functions to support creative production.

AOL CNC Equipment Co., Ltd. is a company with 12 years of experience in CNC cutting machines. From the initial CNC laser cutting machine to the current intelligent blade cutting machine, under the development of the industry, AOL CNC cutting machine is making continuous progress and is committed to solving The user’s problem, therefore, the machine is constantly improving and becoming more practical.

AOL CNC cutting machine has withdrawn from the promotion this month. The purpose is to better popularize the CNC blade cutting machine and bring better economic productivity for more users. If you are now looking for a suitable CNC cutting machine, quickly Come and find out.

AOL digital cutting plotter is 50% off, one can enjoy a special price, and we guarantee to enjoy the same product and service as the original price.

Advantages of digital cutting plotter

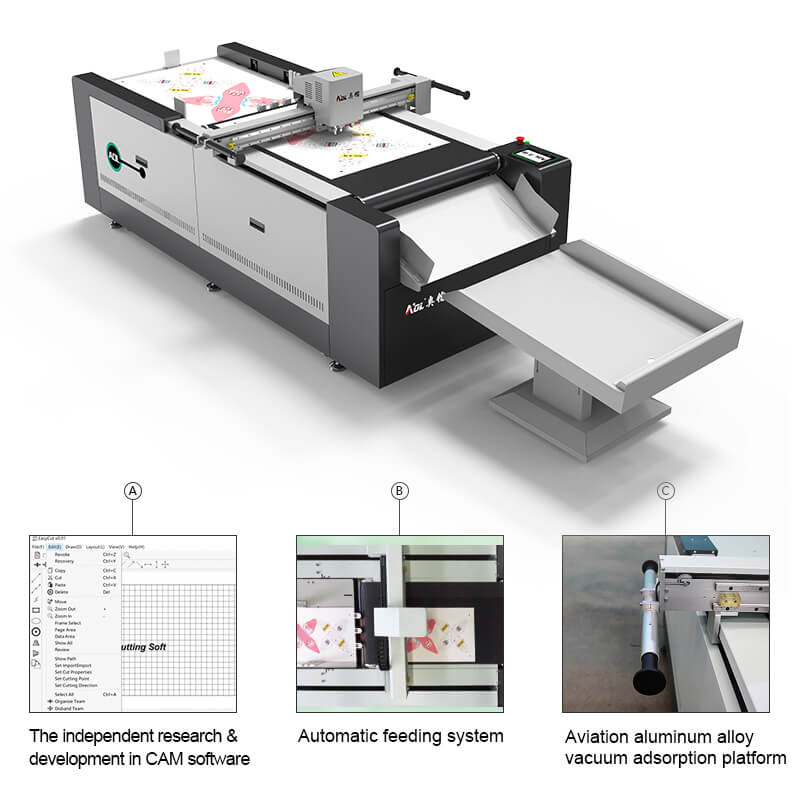

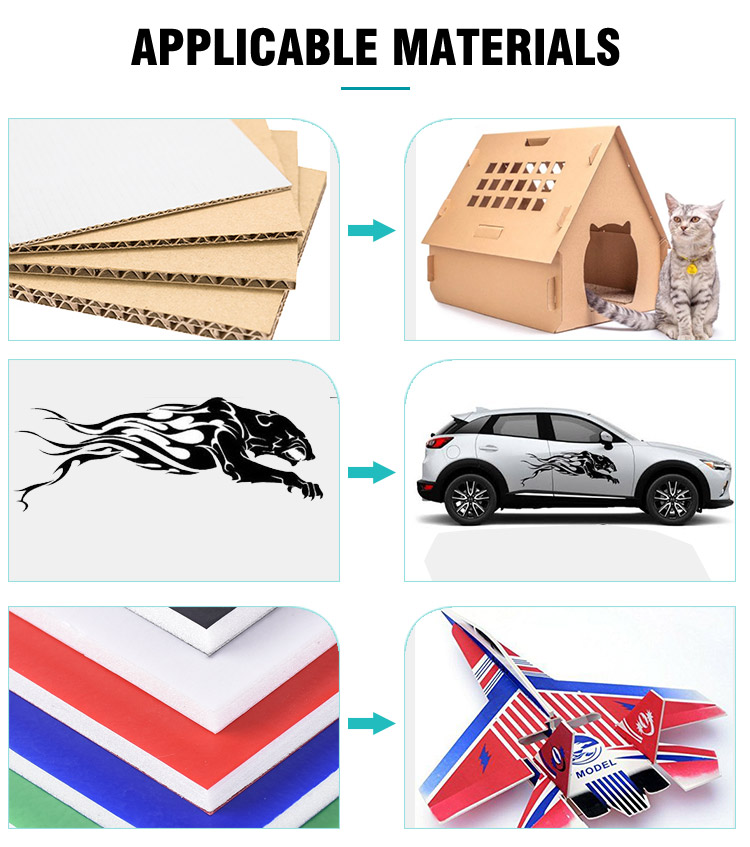

1. Suitable for advertising packaging industry, such as self-adhesive, KT board, cardboard, corrugated cardboard, gray cardboard, flags and other materials. The advertising packaging material industry can be cut very easily.

2. Diverse cutting methods, such as through cutting, indentation making, kiss cutting, V-cut, and other cutting methods can be carried out to meet the needs of cutting different materials.

3. The AOL digital cutting plotter uses the Japanese Panasonic brand servo motor, which provides stable and long-lasting cutting power, and can support continuous cutting for 24 hours.

4. Cold cutting method, blade cutting makes the cutting environment more environmentally friendly.

5. It can be equipped with automatic feeding and receiving devices, and the automatic carving knife is a labor-saving machine.

6. This machine can liberate your body and mind. You only need to design the cutting pattern and design the cutting parameters after importing. After starting the cutting, you do not need to supervise the whole process. The cutting machine can still complete the cutting task very well.

7. Numerical control cutting is flexible, compatible with multi-format files, and can directly import patterns and start cutting.

AOL service

1) Three-year free warranty (except vulnerable parts), free inspection and maintenance of main components.

2) Provide lifetime free technology upgrade service

3) Wearable parts (such as blades, workbench covers) are always available at cost when needed.

4) Free operation training is conducted in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support can be provided when needed.

Learn more about product performance and company services, leave a message about your content, and professionals will give you feedback.

AOL CNC Equipment Co., Ltd. is a high-tech enterprise specializing in the development, manufacturing, sales and after-sales service of flexible material cutting and laser cutting machines. It mainly includes CNC intelligent blade cutting machines, internal engraving machines and other types of cutting machines. It can meet the cutting processing of acrylic internal engraving and flexible materials of different materials, and is widely used in advertising packaging, composite materials, carpet industry, clothing textiles, automotive interiors, and leather industries. In addition, AOL also has an independent CNC cutting machine brand AOYOO.

AOL CNC Equipment Co., Ltd. is a high-tech industry in China, an AAA-level credit enterprise. The product quality has undergone multiple tests and the after-sales system is complete. It has provided reliable CNC cutting machines for more than 8,000 users worldwide, and has provided many users Professional industry cutting assembly line solutions.