At present, most of the clothing industry adopts traditional manual cutting. The biggest problem encountered is manual error, and it is difficult to maintain accuracy. If it is cut in large quantities and multi-layered, it will lead to polar production efficiency. , high efficiency, multi-purpose machine, replacing labor, is an essential equipment in the clothing industry. AOL has been engaged in the research and development and sales of automatic cutting machines in the clothing industry for more than 12 years. It knows the pain points of the industry. What can garment cutting machines bring to the industry? What is the problem facing the clothing industry now? What materials can be cut by the knife and many other questions, please read on to learn more!

Let's watch a video to learn about the garment cutting machine

At present, the cutting problems faced by the clothing industry are as follows:

First: New employees can’t come in, old employees can’t keep them; employees have higher requirements for wages, benefits, and housing, and pay more attention to working hours, rest systems, and living and accommodation conditions, especially when the clothing industry is in the off-peak season. , the treatment of workers is more obvious. In the off-season, it is necessary to pay high wages to support workers, which is difficult for enterprises. In the peak season, when a large number of workers are needed, it will be more difficult for enterprises to recruit workers everywhere, etc.

Second: the mobility of personnel is relatively large. Many workers rely on technology to make a living. As long as the wages of other factories are relatively high, the workers will go with them.

The third worker needs a manual drawing board. Generally, it takes at least 1-2 hours to draw a set of patterns. 10 sets of patterns can be drawn in one day. After drawing the pattern, manual cutting is required. . The technology is general labor, and the efficiency is low. It is also necessary to consider whether the cutting accuracy is satisfactory. If the cutting accuracy is not high, this version will be wasted, and the waste is relatively high.

What solutions does the clothing cutting machine bring to the recruitment difficulties of enterprises:

What solutions does the clothing cutting machine bring to the recruitment difficulties of enterprises:

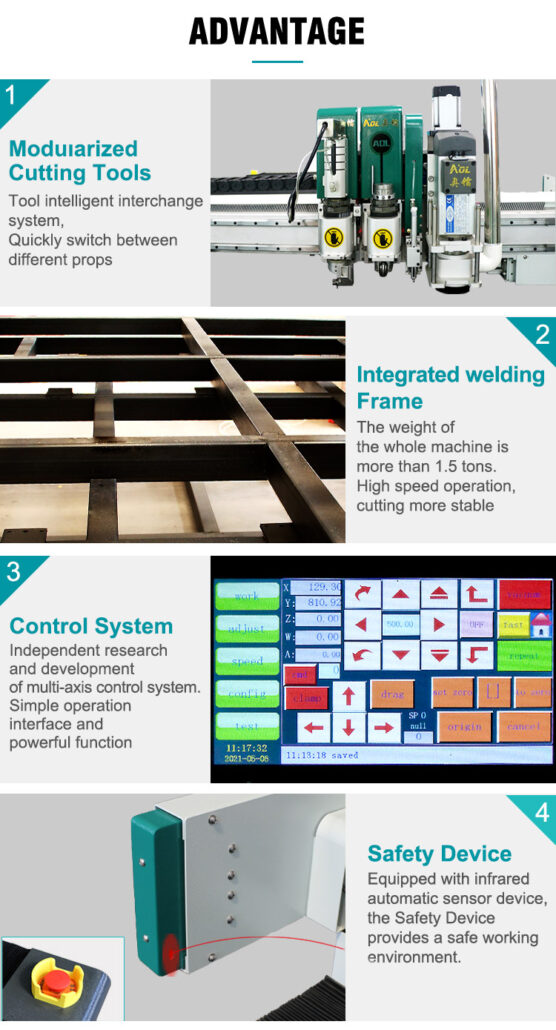

1. One-key import of Ao Lei CNC self-developed software, connect to a computer, input graphics and cut, ordinary workers are skilled at work within 2 hours, freeing the trouble of manual drawing board

2. There is a self-developed Super Nesting Master software. According to how to save materials, typesetting and cutting are performed, the utilization rate is increased by more than 10%, and labor and raw materials are saved by more than 500,000 per year, which greatly improves the competitiveness of products.

3. The Taiwan linear guide drive system is used, and the cutting accuracy reaches ±0.1mm, which is higher than manual cutting and has less waste. Greatly improve efficiency

4. The blade cutting is intelligent, environmentally friendly, efficient, no odor, no burrs, no burrs

What knives are available for AOL CNC cutting machines, and which materials can be cut?

1. Vibrating knife

It is mainly used for cutting thicker materials, generally cutting materials with a thickness of 1.5-2cm, such as KT boards, car mats, floor mats, leather, etc.

2. Round knife

Cutting by blade rotation is mainly used for soft and thin materials. The thickness of the material needs to be less than 1CM, such as cloth, soft leather, etc. Generally, multi-layer cutting cannot be performed.

3. Air Knife

Compressed gas-driven knives are mainly used to cut thicker materials, such as thick foam, etc., and can even cut multiple layers.

4. Drag knife

It is generally used to cut very thin plastics, PVC, leather, posts, etc., generally for single-layer cutting, and cutting without ripples.

5. Indentation

Also known as the pressing wheel, it is mainly used for the processing of the carton. The pressing wheel is used to press out the traces of the folded part of the carton, which is convenient for later forming.

In addition to the choice of cutting tools, the machine can also choose a vibrating knife cutting machine with a CCD camera. The industrial CCD camera is mainly used to collect material information (pattern and shape), and is professionally used for rapid information collection of irregular materials or printed pattern materials. Achieve fast and accurate cuts.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.