From 2020 to the present, COVID-19 is still going on. In order to contain the epidemic, medical supplies manufacturers have resumed work urgently, and they are going all out to make medical supplies such as medical protective clothing. In the production and processing of medical protective clothing, you can see the figure of the medical uniform cutting machine. In order to fight against COVID-19, the medical clothes uniform cutting machine actively participates in the battle against the epidemic.

In terms of the processing efficiency and processing quality of medical protective clothing, the uniform cutting machine for medical clothing has more advanced cutting technology and production lines. The traditional cutting and cutting process of the knife die is complicated, the labor cost is high, and the processing accuracy is inevitably low and easy to remove Edge off-line and other phenomena, and the blade cutting process can be easily dealt with, with its high precision, no burrs, smooth incisions, and can cut any complex shape, giving medical protective clothing more possibilities for processing.

Among many medical uniform cutting machines with different functions and features, AOL CNC vibrating knife automatic feeding cutting machine is an artifact in medical protective clothing cutting. It can be cut for a variety of protective clothing materials, and one machine can solve all cutting problems, and for the cutting of non-woven fabrics, the automatic feeding cutting machine can make the edges of the non-woven fabric of protective clothing smooth and non-spinning when cutting, and at the same time. , The automatic feeding cutting machine can realize double-head asynchronous multi-layer cutting of different parts, different sizes, different sizes and irregular patterns of protective clothing fabrics in the same width.

What are the types of medical disposable protective clothing fabrics?

Medical protective clothing can be divided into woven, non-woven and composite materials according to the organizational management structure design of the fabric; according to different periods of use, it is generally divided into disposable type (one-time use), limited-time type and reusable student-use type. ; In terms of processing composite information technology, there are three types of methods: data processing, coating and lamination.

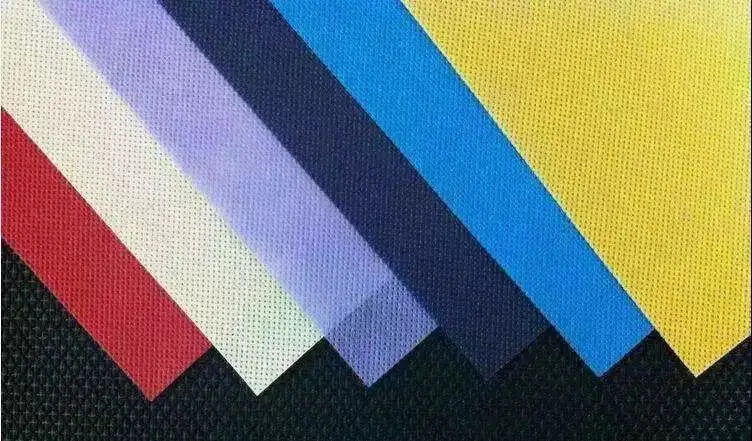

Due to the different raw materials used, protective clothing has different properties. At present, several non-woven materials for medical protective clothing that are being sold and developed in the domestic market are mainly as follows:

Polypropylene Spunbond Fabric: Polypropylene spunbond fabric can be antimicrobial, antistatic treated, made into protective clothing for antibacterial, antistatic protective clothing. Compared with traditional cotton protective clothing, protective clothing polypropylene spunbond is undoubtedly a big step forward. Due to its low price, it is also disposable.

Polyester fiber and wood pulp composite spunlace cloth: the material feels soft, close to traditional textiles, can be treated with three kinds of anti-alcohol (anti-alcohol, anti-oil), anti-static, antibacterial, etc., and can be sterilized by gamma rays. Good medical protective clothing material. However, its anti-static pressure is also relatively low, and its blocking efficiency against virus particles is relatively poor, so it is not an ideal protective clothing material.

A polypropylene spunbond-meltblown-spunbond composite non-woven fabric: Meltblown fabric is characterized by small diameter of fiber cells, large specific surface area, fluffy, soft, good drapability, low resistance of filtration system, high efficiency of filtration technology, The ability to resist hydrostatic pressure treatment is strong, but the strength is low and the wear resistance is poor, which limits the development of its application research field to a considerable extent.

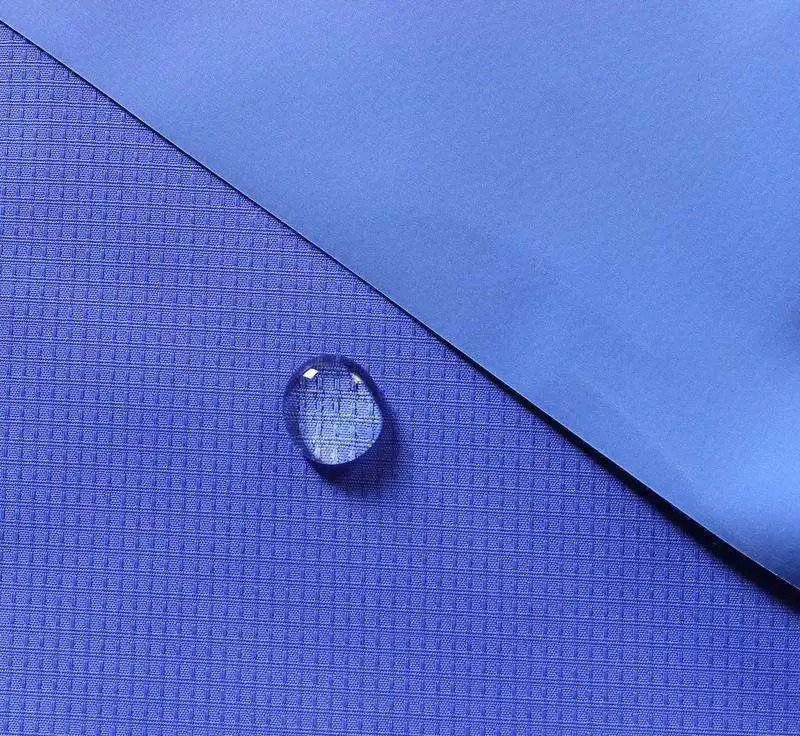

Polymer-coated fabrics: In many types of coatings, polyvinyl chloride, polyethylene, neoprene, and various other synthetic rubbers, the water resistance of this type of protective clothing is used to protect the fabric from particles of bacteria Barrier properties are very good and reusable.

Polyethylene has breathable film/non-woven composite fabric: has strong tensile strength, good air permeability, greatly improves comfort, can withstand disinfection, non-toxic ingredients, gram weight 60~100g/m2, has good Cost-effective, medical disposable protective clothing made of it can protect medical staff from pollution sources, overcome cross-infection, and play an effective protective role.

In addition to the non-woven fabrics of medical protective clothing, the automatic feeding and cutting machine belonging to the medical clothes uniform cutting machine includes the cutting of various medical supplies fabrics, such as medical bed sheet fabrics, pillow fabrics, surgical gown fabrics, quilt fabrics, etc. At the moment when medical supplies are in short supply in response to the epidemic, automatic feeding and cutting machines can quickly respond to production.

If there is anything else you want to know, please contact us, we will answer you as soon as possible!