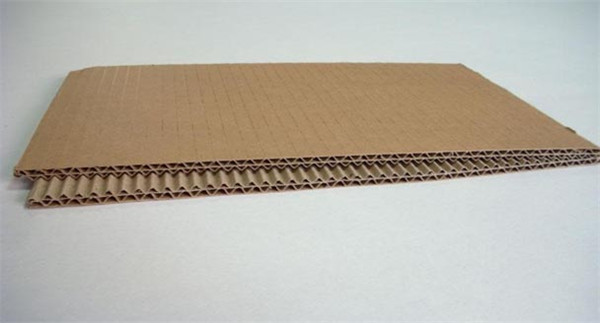

Corrugated paper is a common packaging material in life. It is used in the basic packaging of various items. The demand is very high. Due to the low cost of corrugated paper, it is often processed into packaging boxes of different sizes and even special packaging boxes. Special-shaped boxes and ordinary punching machines are not suitable for cutting due to the high cost of molds. It is impossible to purchase a single equipment for production. Most of the corrugated cutting machine manufacturers purchase also need to meet the needs of cutting other materials, such as pearl cotton, hollow boards, packaging films, and pearls. Cotton etc.

As technology continues to develop, automated production has become a common choice for low-volume manufacturers. However, among the many automated production equipment, how to choose an equipment that suits their own production needs and can meet high cost performance has become a major challenge faced by many small batch manufacturers. Today let me explain the advantages and cutting solutions of the new era of packaging material cutting!

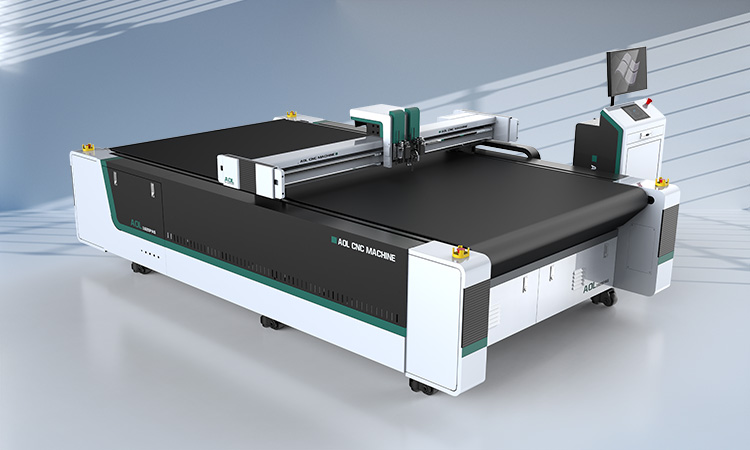

The corrugated box proofing and cutting machine is a blade cutting computer intelligent equipment. The equipment adopts data cutting and does not require molds, which can save a lot of costs. It supports corrugated paper, EVA, pearl cotton, packaging paper, hollow board, pearl cotton cutting equipment and other materials. The process supports automatic feeding, cutting, creasing, beveling, unloading, etc.

This equipment has three major cutting advantages: high precision, high efficiency, and material saving:

1. High precision. The equipment adopts a pulse positioning system and a specially customized body. The positioning accuracy of the whole machine is ±0.01mm, and there is zero error in repeated cutting.

2. Cutting efficiency, the whole machine can replace 4-6 manual workers. The equipment also has a self-developed cutting system with an operating speed of 2000mm/s.

3. Save materials. This equipment has a self-developed typesetting system that can typetype a variety of materials. Typesetting saves more than 15% of materials.

How does a corrugated box cutting machine work? Check it out via video!

Among various forms of paper packaging, color box packaging has developed the fastest. It is widely used in tobacco, food, medicine, daily chemicals and other fields related to people’s lives, and the demand is still expanding.

For the advertising packaging industry, the vibrating knife cutting machine can quickly locate and identify and automatically find edges for cutting, which greatly reduces the workload of the operator. Suitable for cutting and producing KT boards, herringbone boards, self-adhesive, corrugated honeycomb boards and other materials.

The sturdy construction of AOL CNC cutting equipment enables long-lasting and efficient operation. The experienced Color Lab team also provides complete equipment installation and service. All the equipment offered by us adopts the latest technology to meet the requirements of intensive production processes. We invite you to familiarize yourself with our recommended equipment models, equipment that will help your business grow.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/