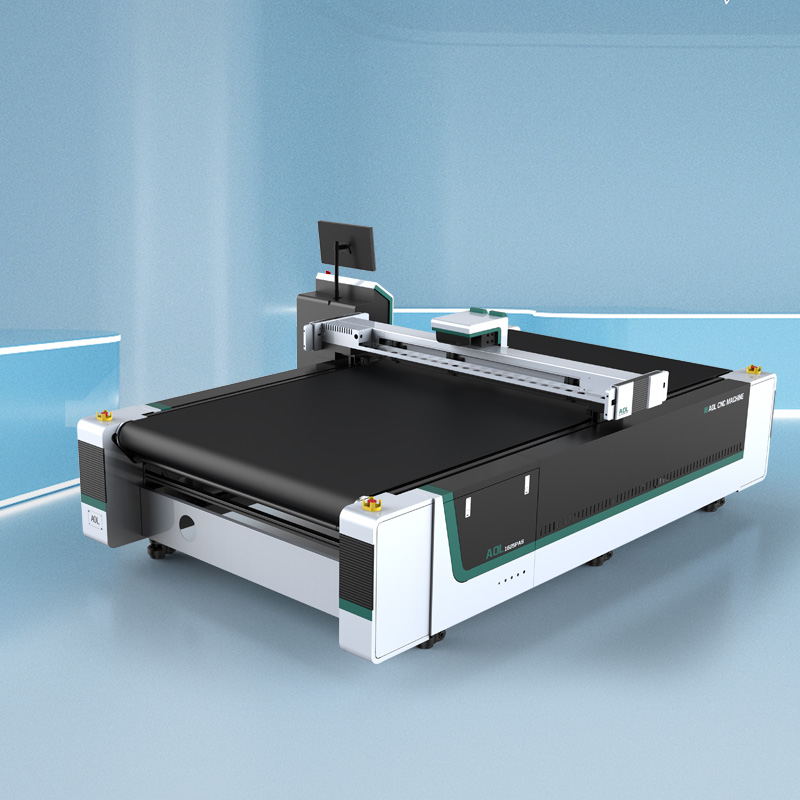

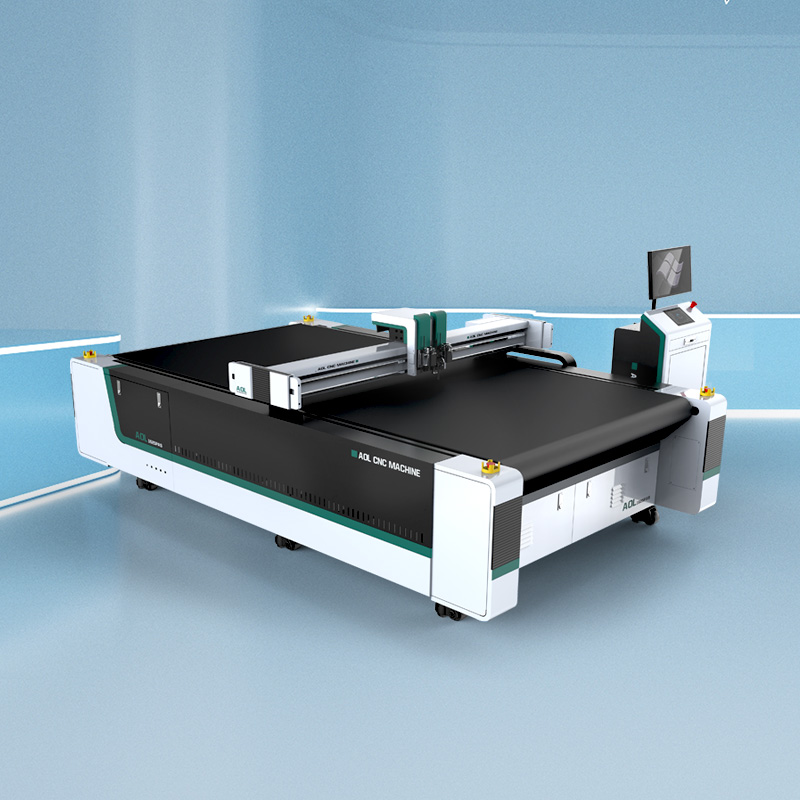

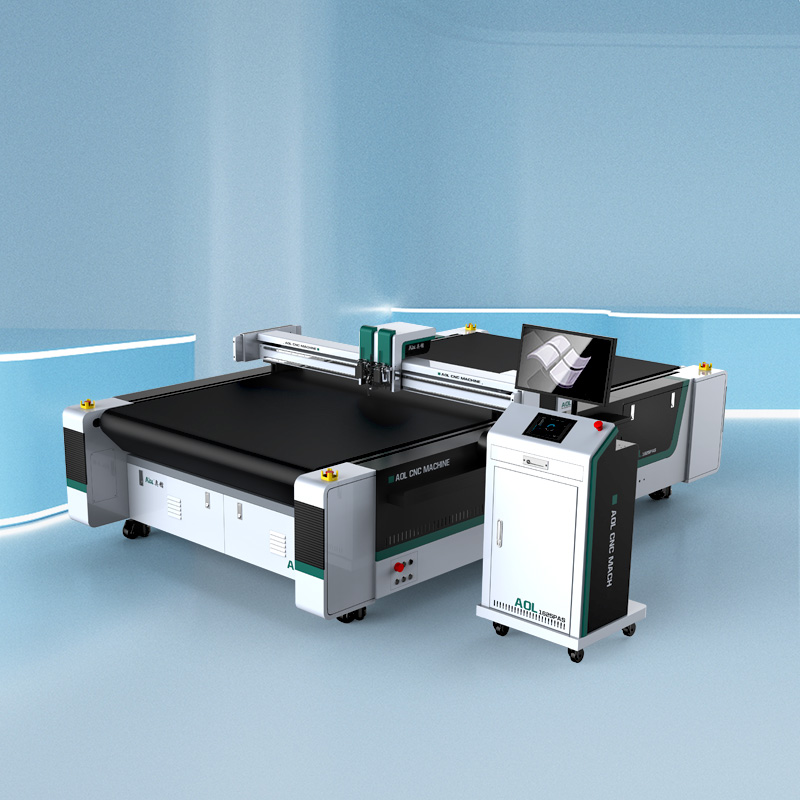

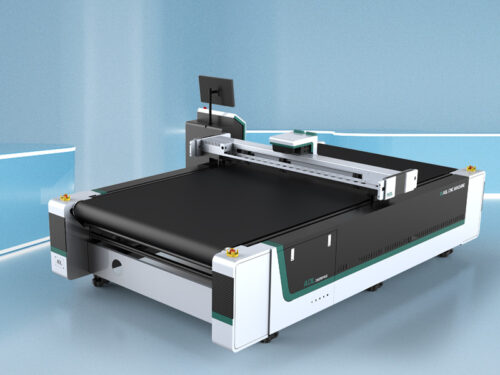

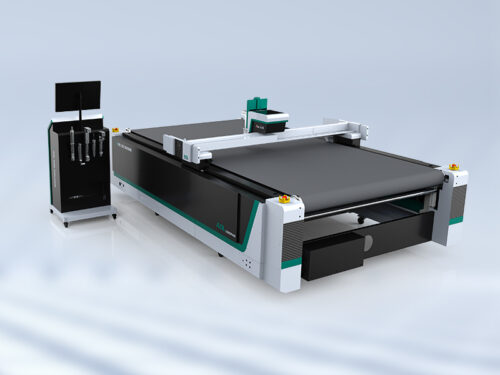

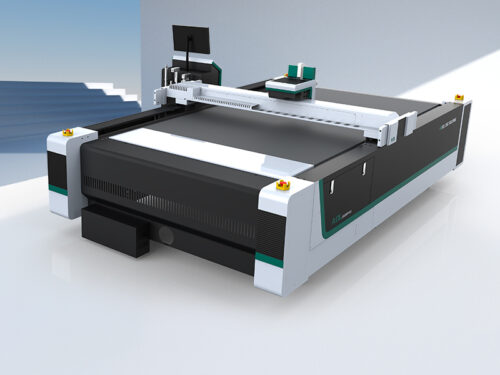

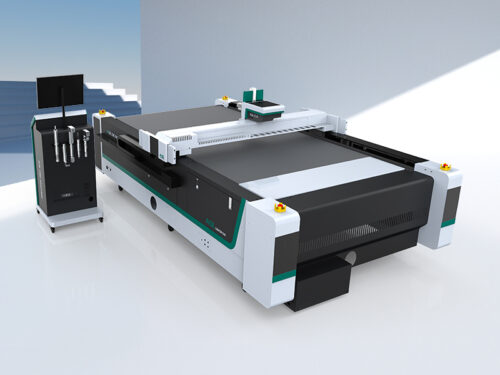

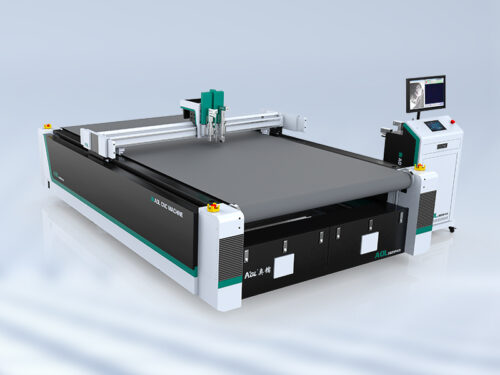

Features of Automatic Corrugated Box Making Machine

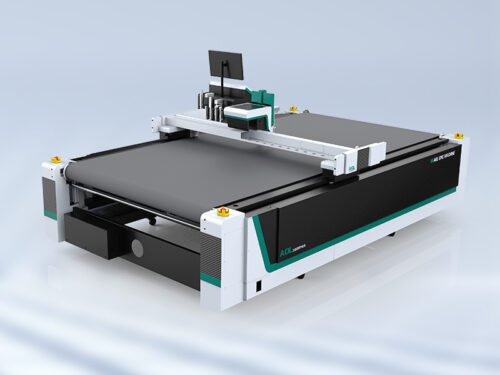

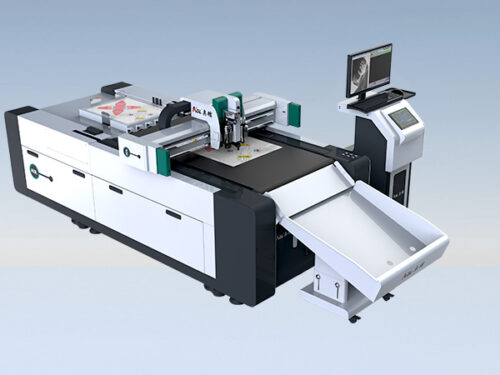

Full modular combination:Oscillting tool+Milling tool can be swithched and cut hard and soft material freely.Reduce corrugated box making price. Features of Automatic Corrugated Box Making Machine

1.Specially developed for cutting, punching and marking on stickers, plastic films and other volume materials.

2.No mold, successfully replaced the traditional die-cutting, without cutting graphical restrictions, cutting speed, short processing cycle.

3.Flight of high-speed galvanometer cutting, continuous automatic cutting of rolls of printed stickers and other materials.

4.Color sensors to locate the cutting graphics than the camera positioning, precision die-cutting, after focusing the optical principle, so that spot more detailed and cut better.

5.Correction system with automatic admission to feed more precise, in order to ensure the die-cutting accuracy, feed speed up to 60m/min, to ensure the efficiency of cutting.

Advantages of Automatic Corrugated Box Making Machine

.jpg)

Application of Automatic Corrugated Box Making Machine

Applicable materials of Automatic Corrugated Box Making Machine with automatic feeding Leather, fabric, textile, cardboard, plastic box, fiber glass,corrugated cardboard, sticker, film, foam boardrubber, cloth, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics, carpets, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

Cutting display of Corrugated Box

Parameter of Automatic Corrugated Box Making Machine

| Technical parameters / model | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | Accepting special-shaped customization |

|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500mm | |

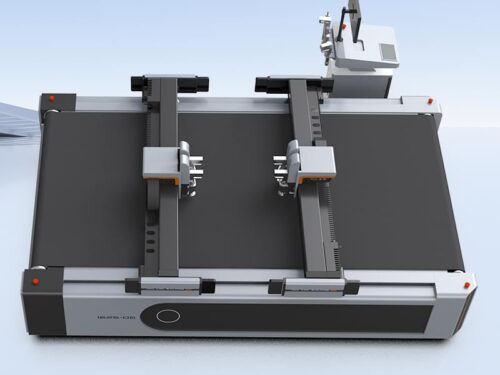

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, semi-cutting cutting, full cutting cutting, camera positioning cutting, edge finding cutting, acrylic milling cutter, cursor positioning, line marking, indentation knife, V-groove knife, etc. | |||

| safety devices | Infrared sensing, safe and reliable | |||

| Cutting speed | 200-2000mm/s | |||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||

| Applicable materials | Various KT boards, Chevron boards, honeycomb boards, car stickers, adhesives, photo frame paper, gray board paper, corrugated paper, EPE foam, PVC board, acrylic sheet, thick foam, etc. | |||

| Material fixing method | Vacuum partition adsorption | |||

| Transmission port | Network port | |||

| Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw | |||

| rated power | 11kw | |||

| Rated voltage | 380V±10%/220V±10%Optional | |||

| Control System | Chinese and English LCD touch screen | |||

| Operating environment | Temperature 0-40°C Humidity 20%-80%RH | |||

| software | Automatic nesting software, camera positioning, large format camera system | |||

| Support file format | AI、PLT、DXF、CDR etc. | |||

AOL SERVICE

Packaging of Automatic Corrugated Box Making Machine

1. Outer packaging: standard seaborne export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture. Flexible packaging machine accessories

3. Personalization: If you have special requirements for packaging, you can negotiate friendly.

Transportion

There are many options for transportation, and the default is sea transportation. If you have special requirements, please specify in advance.

Price, according to your destination information, transaction method, transportation method, we will provide you with a specific quotation.

After sale service

1. Our standard warranty period starts from the completion of delivery. We provide you with a three-year warranty service and professional machine maintenance.

2. The wearing parts (blade, countertop) are sold to users at the lowest price.

Delivery time

we have our own factory. After placing the order, we will start manufacturing the sticker cutting machine. At the same time, we will make a reasonable delay based on the order volume of the month. Our delivery time is about 15-20 days on average, if you want to specify a time, we can arrange a reasonable time to complete the delivery.

Eight reasons to choose Automatic Corrugated Box Making Machine

1. Advanced brand: ten years of professional CNC blades2. R & D advantages: a number of patented technologies, so that the company has a deep deposit

3. Quality assurance: all products have passed European CE certification. US FDA certification

4. High-quality materials: All CNC cutting machine accessories are selected from industry-leading brands.

5. Advanced technology: starting from Germany, foreign advanced technology, technical support

6. High efficiency: implement one-to-one service to improve the efficiency of corporate feedback

7. Personalized customization: With development and design functions, customers can do whatever they want

8. After-sales service: provide three-year warranty service and 24-hour online solutions.

About AOL

AOL CNC Equipment Co., Ltd. is a high-tech enterprise specializing in the development, manufacturing, sales and after-sales service of flexible material cutting and laser cutting machines, mainly including CNC intelligent blade cutting machines, laser cutting machines, laser fiber cutting machines, and laser cutting machines. Various types of cutting machines such as labeling machines can meet the cutting processing of metal materials and flexible materials of different materials, and are widely used in advertising packaging, composite materials, carpet industries, clothing textiles, automotive interiors, and leather industries. In addition, AOL also has an independent CNC cutting machine brand AOYOO.

The company is strong. AOL CNC Equipment Co., Ltd. is a high-tech industry in China and an AAA-level credit enterprise. The product quality has undergone multiple tests and the after-sales system is complete. It has provided reliable CNC cutting machines for more than 8,000 users worldwide. Provide professional industry cutting assembly line solutions for many users,

AOL is committed to multi-industry flexible material cutting solutions for global users. The annual output of high-quality CNC cutting machines in the AOL factory can reach 2000 units, and each machine is provided with a three-year warranty service.

Media information

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

MESSAGE

CONTACT

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

+86-531-88620680

+86-531-88620680

0086-18560162709

0086-18560162709

+86-531-88620680

+86-531-88620680

Reviews

There are no reviews yet.