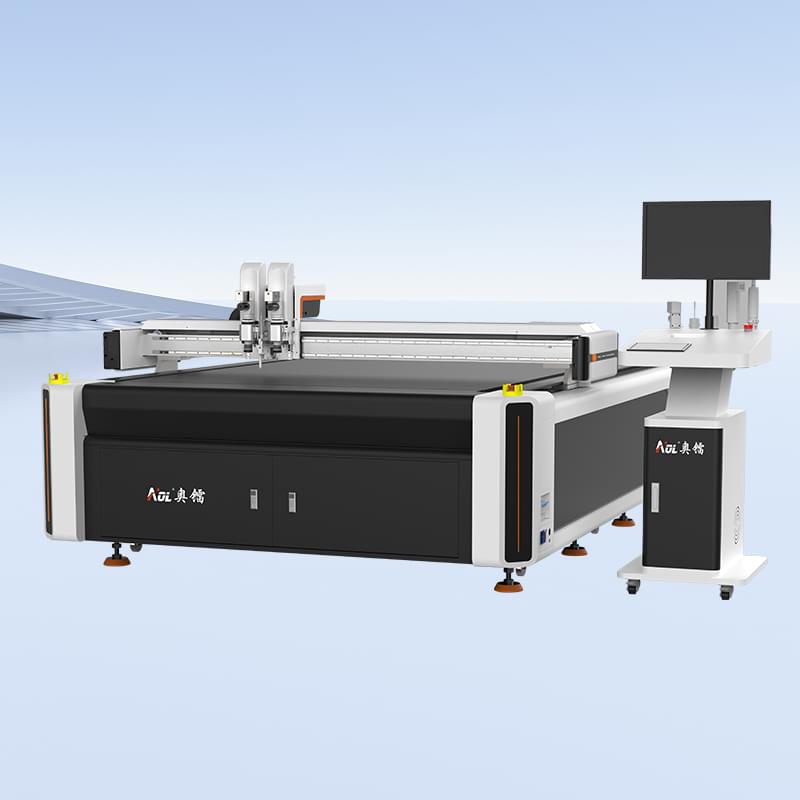

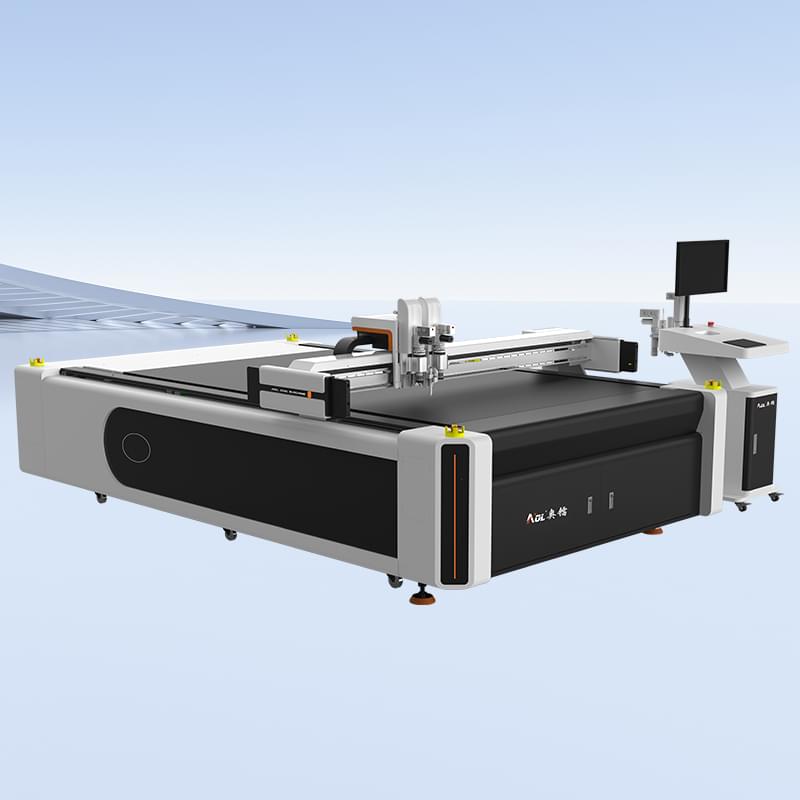

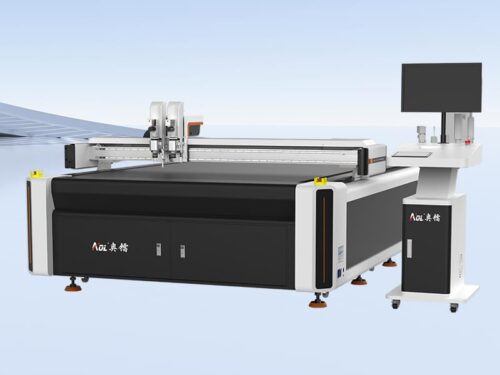

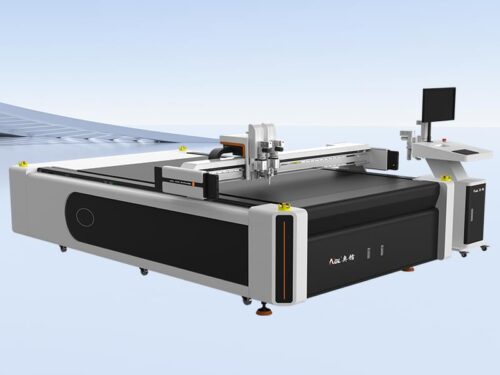

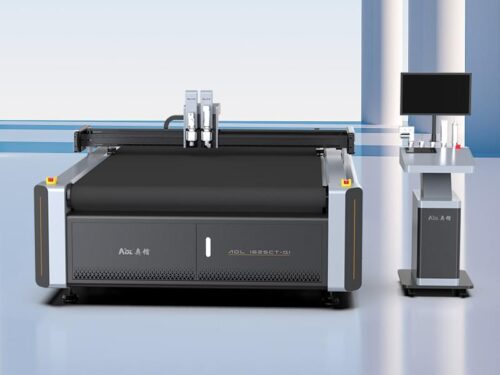

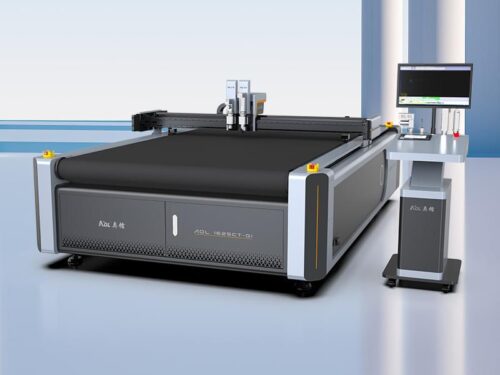

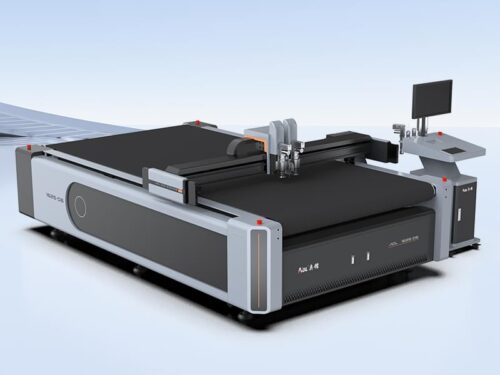

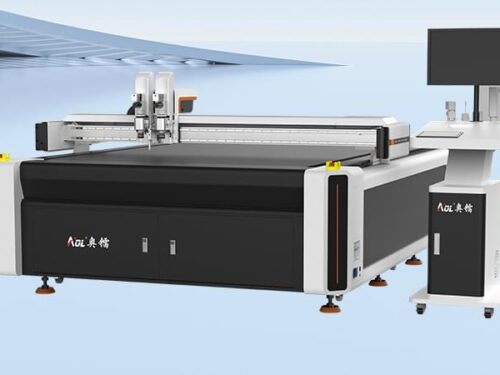

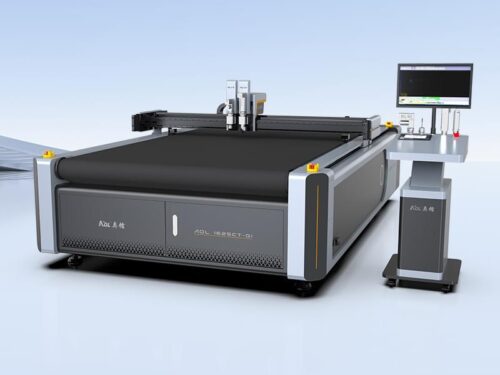

The Automatic Rubber Gasket Oscillating Knife Cutter is a specialized cutting tool designed to efficiently and accurately cut rubber gaskets and other similar materials. These machines use an oscillating knife that moves back and forth rapidly to cut the rubber with high precision and minimal waste.

The CNC Gasket Cutter can be used to cut rubber gaskets. It achieves precise cuts with clean edges, even with complex shapes. In addition, it is a versatile and efficient cutting method suitable for both small-scale and large-scale production applications.

CNC oscillating knife cutting machine is equipped with multi-knife cutting head – oscillating knife, bevel knife, round knife, punching knife, milling cutter, punching roller and marking pen. CCD camera and projector are optional to achieve more precise cutting.

Gasket cutting machines are commonly used to cut a variety of materials, including rubber gaskets. The cutting process includes the following steps:

1. Material Preparation: To cut the rubber gasket, the CNC gasket cutting machine requires a piece or roll of rubber material. The rubber should be of uniform thickness and free of any deformation or blemishes. A vacuum table will hold the rubber during the cutting process.

2. Design/CAD: Using computer-aided design (CAD) software, create the desired shape and size of the rubber gasket. This digital design is then transferred to the cutting machine.

3. Machine Setup: The rubber material is placed on the cutting bed of the gasket cutting machine. The gasket cutting machine is then calibrated to ensure accurate cutting according to the design specifications. This involves setting the cutting speed and blade type.

4. Tool Selection: The gasket CNC cutting machine uses a vibrating blade that moves up and down at a high frequency. The blade can be made of different materials depending on the application. When cutting rubber gaskets, a blade with the right hardness and sharpness should be selected.

5. Cutting Process: Once the gasket CNC cutting machine is set up, the cutting process can begin. The CNC gasket cutting machine follows the designed path and moves the vibrating knife over the rubber material with high precision and speed. As the knife vibrates, it creates a back and forth motion, effectively cutting the rubber.

6. Extraction and finishing: After the cutting process is over, the excess rubber material is removed, leaving only the cut rubber gasket on the cutting bed.

Main features of rubber gasket CNC vibration knife cutting machine:

Oscillating Knife Technology:

A rapidly oscillating blade allows for precise cutting of rubber.

Minimizes heat build-up and material deformation, which is critical when cutting rubber.

CNC Integration:

Controlled by a Computer Numerical Control (CNC) system for precise, repeatable cutting.

Compatible with CAD software for easy import of designs and patterns.

Multiple Cutting Capabilities:

Capable of cutting a wide range of rubber and gasket materials, including natural rubber, synthetic rubber, silicone, neoprene, and more.

Can also handle multi-layer materials and composite gaskets.

Precision and Accuracy:

Ensures precise cuts with tight tolerances, which is critical for gasket applications where sealing performance is critical.

Reduces material waste and increases production yields.

Automation and Efficiency:

Automated cutting processes reduce the need for human intervention.

Increases production speed and output.

Cutting Table:

Equipped with a flat cutting surface, often with a vacuum hold-down system to hold the material firmly in place during the cutting process.

May include a conveyor system for a continuous feed of material.

User-Friendly Interface:

Intuitive control panel and software interface for easy operation and programming.

Real-time monitoring and adjustments increase productivity.

Tool Versatility:

Accommodates a variety of blade types and tools for different cutting needs.

Quick-change tool system minimizes downtime.

Benefits of using a CNC oscillating knife cutter to cut rubber gaskets:

High Precision: Ensures accurate cuts, which are critical to the function of the gasket.

Efficiency: Faster cutting speeds and automated processes increase production capacity.

Quality: Produces clean, consistent cuts with reduced risk of defects.

Cost-Effective: Reduces labor costs and material waste, increasing profitability.

Versatility: Can handle a wide range of rubber materials and gasket designs.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.