Composites are used in a wide range of today’s rapidly evolving technologies – from the amazing racing cars, aerospace, wind turbines, motorsport, sports equipment to pipes and tubes, body armor and more. Recent achievements in composites have enabled manufacturers to develop products that are lighter and more resistant to pressure.

However, as the variety of composite materials continues to increase, there is increasing pressure on composite manufacturers to provide faster, more accurate production (using kit cutting machines) and high-precision composite products.

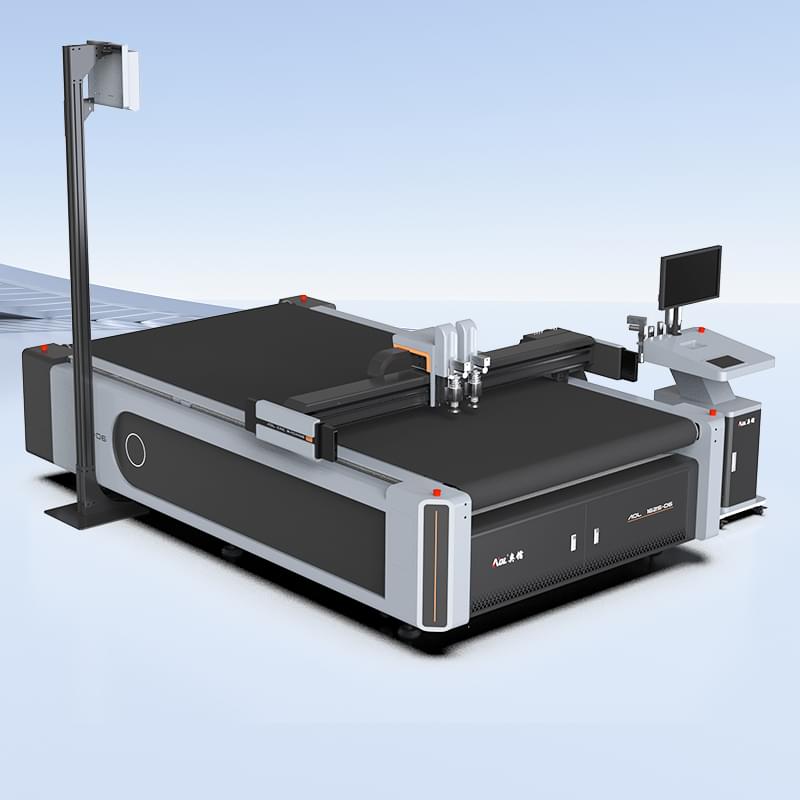

AOL’s composite CNC cutting machines provide modern, fast and flexible laminate and kit cutting technology for composites to meet the most stringent production needs. Our composite kit cutting solutions include the best in CNC cutting technology, custom-sized cutting tables, reliable and affordable service, and a strong support team.

We offer single and multi-layer composite cutting machines, which are manufactured to the highest standards and can be equipped with a variety of tools to tackle the most diverse composite materials: carbon fiber, fiberglass, chopped strand glass, prepreg, unidirectional Materials etc.

To address such a wide range of materials and challenges, we offer the following tools:

Drag Knife – Prepreg Composite

Electric Oscillating Knife – Prepreg and Braided Composites

Driven rotating blades – most types of composites

Pneumatic Vibrating Knife – Most Types of Composites

Drill bits and stamping tool series

Composite computer cutting machines are mainly used for cutting composite materials. For example, carbon fiber, glass fiber, soft glass, prepreg, carbon felt, rubber, graphite sheet, silicone, sound insulation, honeycomb profiles, etc. Equipped with a variety of tools and pens to meet the cutting needs of different materials and provide various personalized cutting services.

Composite material CNC cutting machine has a more flexible and intelligent cutting method

Digital cutting machines are very efficient, accurate and of high quality compared to manual cutting. With labor costs getting higher and higher, choosing smarter cutting methods is a smart choice.

The digital cutting machine is equipped with automatic layout software, automatic feeding system and vacuum adsorption system. The vacuum adsorption system pulls and fixes the roll prepreg, and then imports the designed image into the machine cutting operating system. The digital cutting machine automatically cuts composite materials according to the designed graphics.

Interested in our compound cutting machines?

If you’re interested in one of our composite cutting machines, or you’re not sure if they’re worth the investment, why not get in touch with a member of our team today?Click here to contact us!