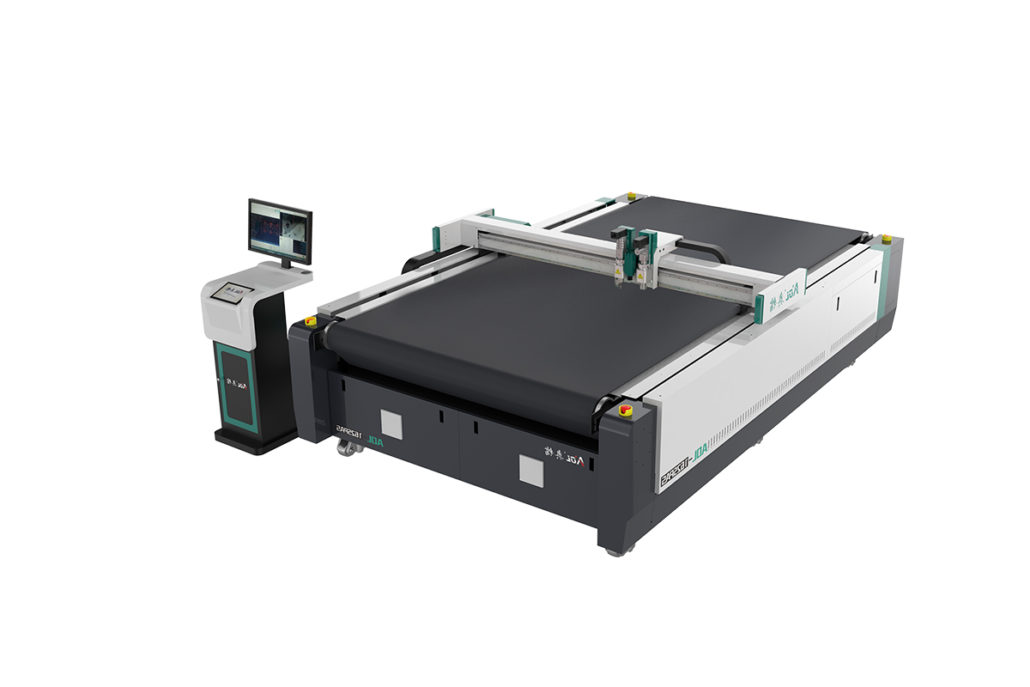

Polyester fiber board, also known as glass wool, is called polyester fiber sound-absorbing board. Generally used in engineering noise reduction: automotive engines, engineering motor seals to alleviate noise. It has a good alleviation effect on high frequency and high decibel noise. AOL CNC equipment cuts polyester fiber board for customers who visit and try cutting, and the cutting and grooving effect is good.

Features of polyester fiber panels material:

sound absorption

The sound-absorbing properties of polyester fiber sound-absorbing panels are similar to other porous materials. The sound-absorbing coefficient increases with the increase of frequency. The high-frequency sound-absorbing coefficient is very large. sound-absorbing properties. The noise reduction coefficient is about 0.8 to 1.10, making it a high-efficiency sound absorbing body in a wide frequency band.

physical and mechanical properties

The polyester fiber sound-absorbing board has the characteristics of sound absorption, heat insulation and heat preservation, and the material of the board is uniform and solid, elastic, tough, wear-resistant, impact-resistant, tear-resistant, not easy to be scratched, and large in width.

Diverse products

Polyester fiber sound-absorbing panels are available in more than 40 colors and can be assembled into various patterns. Surface shapes are flat, square (mosaic), wide strips, and thin strips. Sheets can be bent into curved shapes. It can make the indoor body shape design more flexible and effective. You can even copy art paintings on polyester fiber sound-absorbing panels by computer.

Fire performance

The polyester fiber sound-absorbing board has been tested by the National Fire Protection Testing Center for fire protection parameters. The results show that it has good fire performance and meets the requirements of national standards.

safety

The safety of polyester fiber sound-absorbing panels is reflected in two aspects. On the one hand, the material has excellent mechanical properties, light weight, and will not produce fragments or broken pieces like some brittle materials such as perforated gypsum board and cement fiber compression board after impact damage. The block is at risk of falling. On the other hand, it is the release of harmful substances. After testing by relevant state departments, the standard requirement for formaldehyde emission is ≤1.5㎎/1, and the test result is 0.05㎎/1. It meets the requirements of the national standard GB18580-2001E1 and is directly used in the personnel working area.

Ease of cleaning

Dust removal is easy and maintenance is simple. Dust and impurities can be flicked with a vacuum cleaner and duster. Dirty areas can also be wiped with a towel, water and detergent

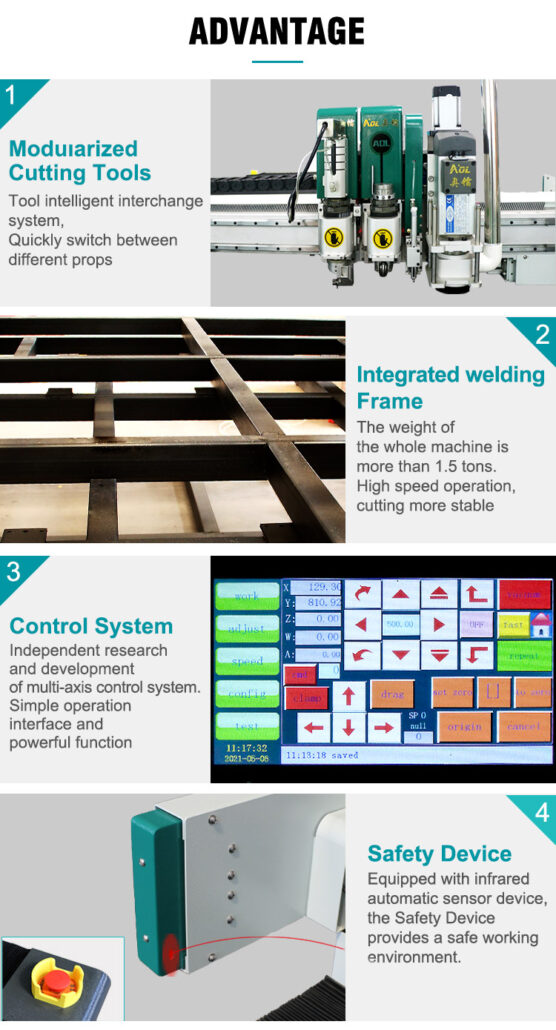

Advantages of polyester fiber panels cutting machine:

1. Independently develop and design CAM software, intelligent software compensates, optimizes the cutting path, and improves production energy efficiency.

2. Using high-quality linear guide, the accuracy error is ±0.1mm.

3. Power saving and variable frequency vacuum adsorption, saving more than 30% of electricity.

4. Super nesting software, the material utilization rate is increased by more than 10%

5. The anti-static system of the whole machine can protect the safety of personnel to the greatest extent.

6. Professional R&D team can provide assembly line supporting solutions

7. Infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

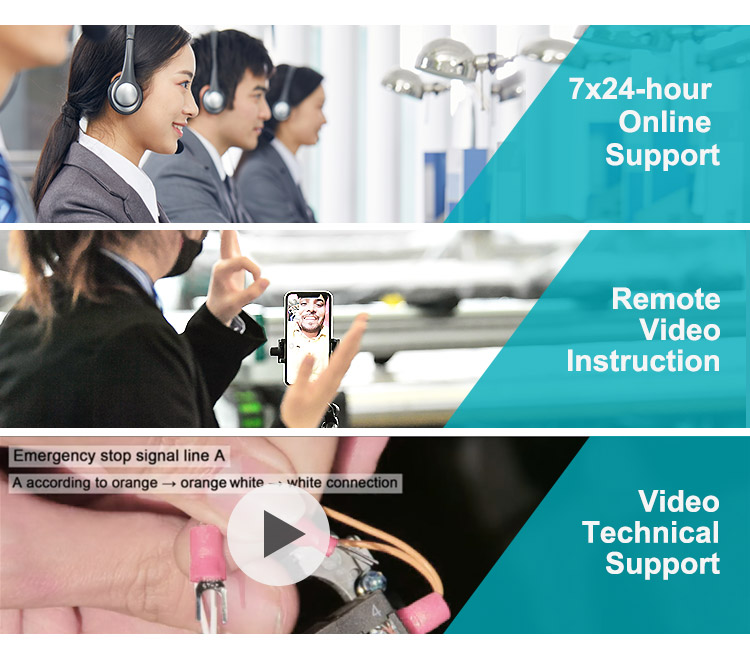

8. If you have any questions, please contact us, we will have professional business personnel to answer all your questions!

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/