The competition in all walks of life is very fierce, followed by the multiplication of higher and higher labor costs and material costs, so we have to take some measures to prevent these high costs, the first thing we think of is If you want to save money, you need an automated machine, and you need a device that can reduce labor costs and various material costs. This can not only improve work efficiency, but also save most of the costs caused by the increase in personnel. Today, AOL CNC Equipment Co., Ltd. introduces a leather cutting machine for leather cutting enterprises. Let’s see what is the difference between manual cutting and leather cutting machine cutting.

From the current market point of view, the price of natural leather has been rising all the way. How to improve the utilization rate of leather is our key consideration, because artificial cutting will cause a lot of waste of raw materials, and reducing the cost waste caused by human factors is a problem that we have always needed to solve; The increasing improvement of the social security mechanism for personnel has led to higher and higher wages for our personnel. At this time, we need a cutting equipment that can simultaneously increase the utilization rate of leather and reduce labor costs, which is particularly important for leather cutting.

AOL leather cutting machine is a computer-controlled intelligent leather typesetting and cutting equipment. It is a new type of automatic intelligent cutting equipment that uses intelligent cutting technology to replace manual labor. The documents scanned by the scanner are input into the computer, and then the super layout software performs the most material-saving layout. The man-machine interface is very simple, and the operator can complete the most basic typesetting operation in a very short time.

The system intelligently optimizes typesetting and cutting, providing better cutting and filling paths, saving more than 30% of materials. The leather material reduces the waste rate, improves the utilization rate of the material, and reduces the cost of manual cutting. At the same time, the leather cutting machine directly replaces the work content of 4-6 workers, reduces labor costs, improves cutting speed, and greatly improves cutting accuracy, which enables enterprises to increase revenue and reduce costs.

If other industries exist, AOL CNC cutting machines can also serve you:

1. Packaging industry: corrugated cardboard, honeycomb cardboard, kraft paper and other packaging boxes (cutting, creasing, dotted line cutting, scribing)

2. Advertising industry: stickers, labels, PP paper, flags, inkjet cloth, light boxes, KT boards

3. Car interior industry: car interior dimensions of various models, as well as leather and artificial leather

Leather and other materials (with multi-model database)

4. Composite materials: EVA, EPE, PVC, soft glass, fiber products (glass fiber, carbon fiber, etc.), thermal insulation cotton, sound insulation board, rubber, etc.)

5. Leather industry: leather materials, artificial leather materials, composite leather materials, etc. (cutting, scribing)

6. Gasket industry: gaskets of various materials (asbestos, non-asbestos, rubber), PTFE (special-shaped, small area cutting)

7. Carpet industry: all kinds of carpets, silk circle carpets, diatom mud carpets and other carpets in various environments (standard or special-shaped cutting)

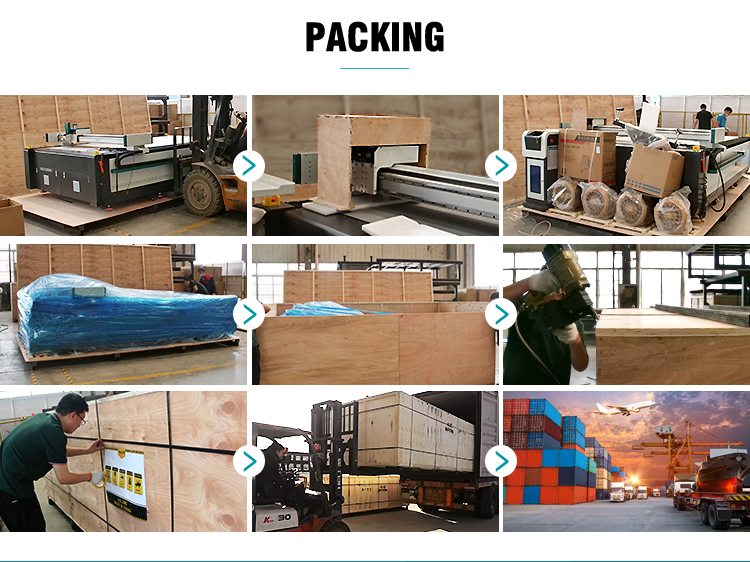

Packaging of the cutting machine:

1. Outer packing: Standard sea export plywood box.

2. Inner packaging: stretchable film and plastic film to prevent moisture.

If you have special requirements, we can negotiate amicably. If you have any questions, please contact us, and we will have professional staff to help you answer!