Sound-absorbing panels use irregular laminated materials to reflect sound to achieve sound-absorbing effects. They are often used in home soft packages, recording studios, theaters, etc. At the same time, the sound-absorbing cotton material also has the function of sound insulation, which can ensure the temperature of the room. The value of the sound-absorbing cotton is higher than the value of the thermal insulation cotton. The sound-absorbing cotton material is more valuable and pays more attention to the processing effect.

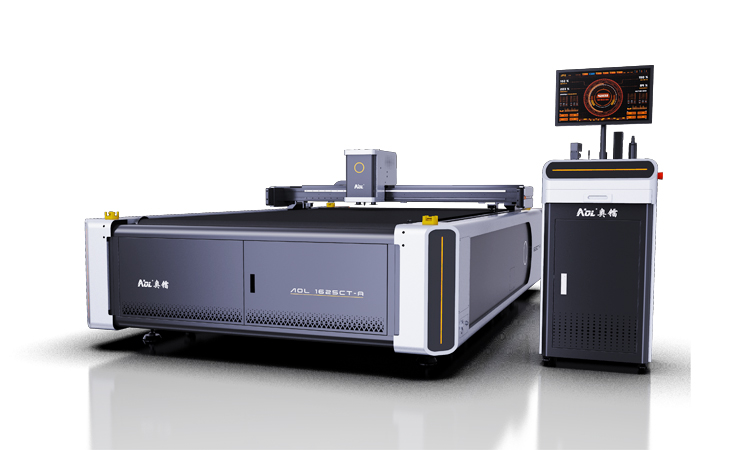

The common cutting forms of sound-absorbing cotton include cutting and grooving. It is difficult for one piece of equipment to meet the cutting needs, and even if it can be achieved, the cutting effect cannot be guaranteed. The vibrating knife cutting machine adopts blade cutting and has cutting and grooving functions. It has the characteristics of no jagged edges, no burrs, and high precision on the cutting edge.

Since its development, it has been accepted by many sound-absorbing panel and sound-absorbing cotton manufacturers. Its low cutting cost, high cutting efficiency, high cutting precision and material saving have been recognized by many manufacturers. The working principle and advantages of the vibrating knife cutting machine are introduced in detail.

The vibrating knife cutting machine has a variety of cutter heads, including pneumatic knives, bevel cutting, dragging knives, vibrating knives, and circular knives, which correspond to different materials. Three types of tools are commonly used for sound-absorbing cotton: vibrating knives, pneumatic knives, and bevel cutting knives. It basically meets the cutting needs of all sound-absorbing cotton and sound-absorbing panel materials.

Some common features and functions of sound-absorbing panel cutting machines:

Precision Cutting: These machines are equipped with blades that are high-precision cutting tools to ensure precise cuts as per the specified dimensions.

Programmable Controls: Many modern cutting machines are equipped with programmable controls that allow the user to enter precise measurements and cutting patterns to automate the cutting process.

Versatility: Sound-absorbing panel cutting machines are versatile in the types of materials they can cut, adapting to a variety of thicknesses and densities of sound-absorbing materials.

Efficiency: These machines are designed for efficiency, capable of cutting multiple panels quickly with minimal wasted material.

Safety features: Safety features such as guards, emergency stop buttons and sensors are often used to ensure safe operation.

Advantages of sound-absorbing panel cutting machine:

1. The cutting effect is good. Due to computer-controlled cutting, the equipment has strong control over various straight lines, arcs, chamfers and other shapes, and will not produce jagged or loose edges.

2. High cutting accuracy. The equipment adopts integrated welding machine technology, pulse positioning, and positioning accuracy of ±0.01mm.

3. Cutting materials are saved. The equipment uses data cutting, which saves more than 15% compared with manual typesetting. Moreover, equipment cutting will not cause waste due to errors.

Factors to consider when choosing an acoustic panel cutting machine include cutting accuracy, cutting speed, material compatibility, ease of use, maintenance requirements, and overall cost-effectiveness. In addition, it must be ensured that the machine complies with relevant safety standards and regulations.

If you want to know more comprehensive content, please click to contact us and we will explain it to you in detail as soon as possible!