With the development of the times and the advancement of science and technology, in order to let everyone keep up with the pace of the times, and to make the shoe pattern cutter better to help you solve various shoe cutting and proofing problems. After a period of research, a new upgrade was made to the AOL shoe pattern cutting machine. It can ensure the cutting speed and at the same time the cutting efficiency.

A few years ago, most shoe manufacturers used manual cutting methods, which was inefficient. When encountering large orders, they often needed to work overtime all night to complete them on time, which caused workers to complain. Some factories will choose semi-automatic equipment for production, but every time a new template sample is encountered, the equipment parts need to be replaced, which is expensive and not very efficient.

In recent years, with the advancement of science and technology, the automatic cutting equipment-shoe pattern cutting machine produced by AOL Equipment Co., Ltd. has come into view and has attracted the attention of shoe manufacturers. You need to set parameters on the software, you can directly cut, compared with the traditional manual production method, the same production volume, the machine only needs one person to operate, the production time is also half of the labor, saves a lot of labor, and improves the efficiency. How to improve efficiency will be explained to everyone.

1. The shoe pattern cutting machine is a kind of numerical control equipment. The cutting parameters only need to be set on the computer software, and the equipment will automatically cut according to the parameters without complicated process flow.

2. The shoe pattern cutting machine has an automatic discharge function, which can improve the effective utilization rate of the fabric and reduce the material cost.

3. Equipped with automatic feeding and receiving function, the fabric can be automatically spread on the table for cutting, and then automatically retracted the cut insole, with a high degree of automation.

4. Camera positioning function, automatic positioning of fabrics to achieve precise cutting.

The use of shoe pattern machine:

Widely used in shoe industry, shoe sample design room, shoe mold, shoe sole factory template cutting, can connect to any shoe industry plane, 2D, 3D shoe sample design software, release shoe samples of different shoe sizes, through the shoe mold cutting machine, Cut out the pattern, you can customize the text in the shoe pattern, half knife, full knife. At the same time, it can cut white cardboard, red cardboard, PVC board and other materials in two ways.

Advantages of shoe pattern cutting machine:

1. Greatly improve the utilization rate of materials: the safety distance between cuts can be set in the software, saving 6-8% of cardboard.

2. Excellent transmission system: imported guide rails, accessories and servo motors are fully used. Fast speed, high precision, low sound, stable work, can guarantee 24 hours of uninterrupted work.

3. High-efficiency and low-cost cutting system: The shoe mold system cuts quickly and beautifully, saves the cost and time of knife mold manufacturing, allows new shoe samples to be put into the market in time, quickly adapts to market changes, and repeatedly modifies sample archives.

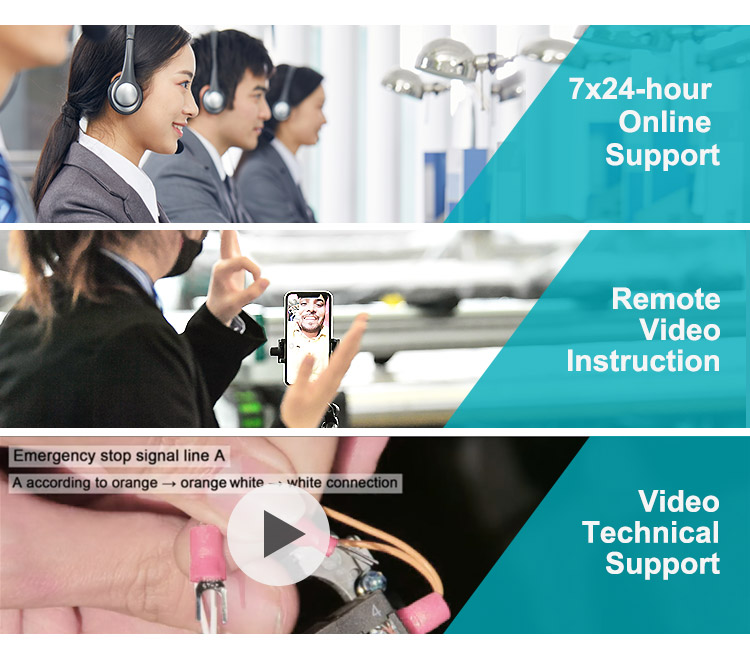

The above briefly introduces the advantages of the lower shoe pattern cutting machine and why it is favored by many bosses instead of labor. If you want to know more about our equipment, please click to contact us!

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/