Different from ordinary carpets, industrial carpets are a special safety carpet switch that can play a role in regional protection. By detecting enough pressure, a switch signal is generated to achieve regional safety protection. It has a large protective area, It has the characteristics of rapid reflection and good protection effect. It is mainly used around mechanical safety protection, such as pipe bending machines, forming machines, stamping equipment, robot workstations, etc.

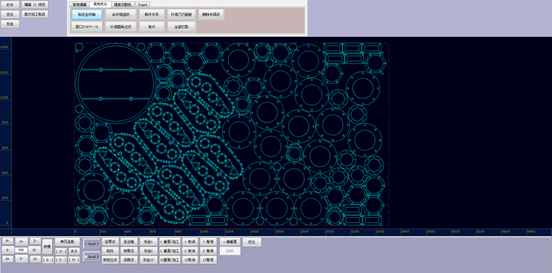

There is a market when there is demand. Now many manufacturers choose to use industrial carpets for safety, and the market demand is also growing. Today, I will tell you about the most basic step in the production process. The equipment that needs to be used – industrial carpets cutting machine.

Before the emergence of industrial carpet cutting machines, most of them were cut manually. There are various problems in the process of manual cutting. Let’s take a look at the problems encountered in manual cutting.

First of all, manual cutting will have certain limitations. In the early stage of cutting, it is necessary to punch the board first, and then cut the material. On the one hand, the template requires a certain cost. This step will waste a lot of time, greatly affect the efficiency of cutting, and it is very labor-intensive. Now the labor cost has been rising, and time is also money. This step has increased the cost of the product!

On the one hand, it is the problem of cutting accuracy. It is difficult to control the accuracy of manual cutting of carpets, especially after several hours of continuous work, the accuracy affects the quality of the product and directly reduces the competitiveness of the product. Compared with the above two points, this point has a greater impact. There is also manual control of materials, and there is relatively more waste, so the cost of raw materials is relatively high.

Next, I will tell you about the advantages of the industrial carpet cutting machine, and the size of the cutting machine can be customized according to your needs!

From the perspective of cutting efficiency, the effect of industrial carpet cutting machine is 3-5 times that of manual cutting. One machine can replace the work of 4-6 people, and the machine operation is simple and easy to use. Ordinary workers can be on duty within 2 hours. It solves the current problems of difficult recruitment and high labor costs. The key point is that the machine can work 24 hours a day.

Finally, our cutting equipment will undergo 72 hours of uninterrupted high-load proofing and trial cutting before leaving the factory to ensure the normal operation of the machine.

From the above, you can learn that we can reduce various costs through the industrial carpet cutting machine, including the cost of board making, the cost of materials, and the cost of labor. For the same product quality, the lower the cost, the higher the competitiveness. The quality of products produced by industrial carpet cutting machines is also higher than manual cutting in all aspects, which may be the reason for the high quality and low price.

And this industrial carpet cutting machine can not only cut industrial carpets, but also common printed carpets, lawn carpets, plastic carpets, etc., but also cut clothing fabrics, car interiors, gasket materials, glass fiber, sound-absorbing panel materials And a variety of composite materials, one machine can be applied to a variety of flexible materials, greatly increasing the added value of the enterprise!

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/