The timeless all-purpose fabric – plaid.

Plaid cloth can be said to be very common in our lives. It seems to have a kind of magic power, and it can appear naturally in various scenes without being abrupt and showing a different style.

We should be most familiar with plaid clothing, plaid home textiles, full of vitality and youthful atmosphere, make people feel better, can be fashionable, can be nostalgic, can publicize individuality, and can also restrain heart.

If there is a market, it is worth making. Now we have many manufacturers of plaid clothing and home textiles. What should we do if we want to get a share of it?

What I want to talk about today is how to reduce costs, increase product quality, and improve product competitiveness in the process. This process is the cutting of materials.

Why is manual cutting gradually replaced?

The manual cutting of plaid is the most troublesome in the step of aligning the lattice, the efficiency is very slow, and the accuracy is low, time-consuming, labor-intensive and material-intensive, which greatly increases the cost of the product and reduces the competitiveness of the product.

When playing the board drawing board, the increase of styles leads to the increase of board types, the accumulation of board types is serious, the cost increases, and the production efficiency of products is reduced.

Manual cutting, low precision, serious material waste, and inability to work continuously, coupled with the fact that skilled workers are becoming more and more difficult to find, make it difficult for many manufacturers.

AOL plaid automatic cutting machine, automatic aligning, one-click cutting, solves the problem of manual cutting, and leads a new era of cutting.

AOL plaid automatic cutting machine adopts projection automatic aligning, which largely solves the cumbersome degree of manual aligning process, greatly saves the time of this procedure, increases efficiency and reduces cost, and has high aligning accuracy!

Using this cutting machine does not need to make a board, and it can be cut by importing data, which saves the time, labor and cost of making a board and draws a board, and reduces the production cost of the product.

The machine cutting has high precision and high speed, one machine can replace 3-5 workers, in addition, it can work continuously for 24 hours. And it comes with an intelligent typesetting system, which minimizes the waste of materials and saves more than 10% of labor.

In the case of the same raw materials, the reduction of production costs, the saving of materials, and the reduction of labor costs can allow products to have a lot of room in price and improve the competitiveness of products.

Through the above comparison, it is not difficult to find out why manual cutting will be gradually replaced, the times are developing, technology is also advancing, and you also need to keep up with the pace of the times.

If you are in the industry that needs to cut this process, or you want to be in the manufacturing industry, you can come to consult us if you want to know anything. In the future, AOL cutting equipment will become your most solid backing!

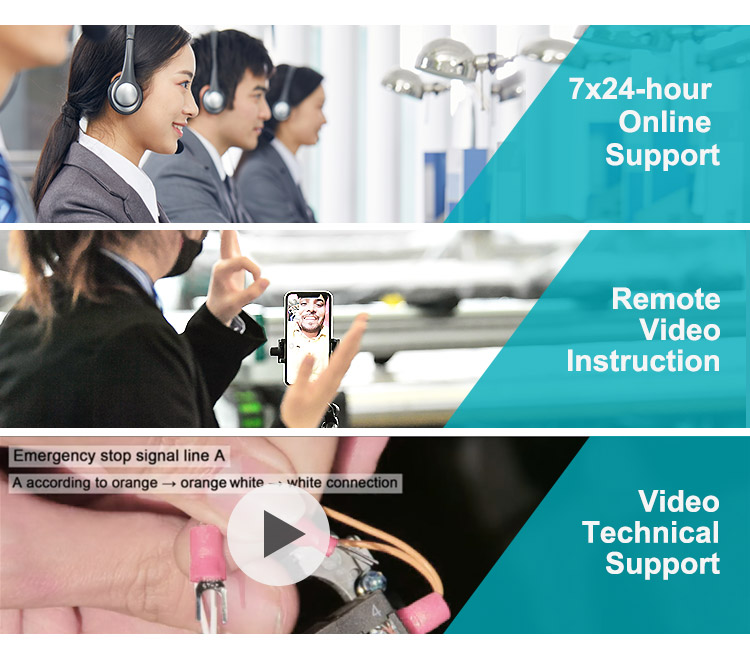

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/