Most of the sound-absorbing materials are loose and porous materials, such as slag wool, blankets, etc. The sound-absorbing mechanism is that the sound wave penetrates into the pores of the material, and most of the pores are open pores that penetrate each other inside, which are subject to friction and viscous resistance of air molecules, and make the sound absorbing. The tiny fibers vibrate mechanically, thereby converting sound energy into heat energy. The sound absorption coefficient of this kind of porous sound-absorbing material generally increases gradually from low frequency to high frequency, so the sound absorption effect of high frequency and medium frequency is better. , Anti-mildew properties.

Sound-absorbing panel is a common decoration material. It is often cut and carved into any shape for beauty, and then spliced into a sound-absorbing and beautiful wall or ceiling. The primary processing method of sound-absorbing panel decoration is punching, slotting, cutting, etc. The manual cutting will cause uneven cutting, burrs, and low efficiency. With the development of science and technology, the emergence of CNC vibrating knives has solved many problems for many manufacturers.

The sound-absorbing panel vibrating knife cutting machine adopts a cold cutting process, cutting with a blade, and also has a super typesetting software and an automatic error compensation system, which can not only save raw materials and labor costs, but also ensure accurate cutting.

Our machine adopts advanced and mature rolling table design, which can customize the cutting width of your material according to your requirements, the theoretical cutting length is not limited, with vacuum adsorption design (small sample adsorption is no longer difficult) and automatic camera positioning function, which can automatically The positioning and cutting of the substrate is completed, and the contour can be cut without manual positioning.

And it is also suitable for a variety of industries, widely used in clothing industry, leather industry, automotive interior industry, composite material industry, gasket industry, luggage industry, advertising packaging industry and many other flexible material industries.

What types of sound-absorbing panels do you know? The following guides you to understand:

EPDM sound insulation sponge: EPDM sound insulation sponge is a material with a porous structure, which has the properties of good elasticity, shock resistance, sound insulation, low density and heat insulation. With good physical and mechanical properties, weather resistance and processing performance, epdm sound insulation sponge is soft and resilient, and is widely used in fields with higher environmental requirements, such as: ports, marine, aviation, military equipment, etc.

Aluminum foil glass fiber insulation cotton: a kind of insulation material with very strong waterproof performance. As a raw and auxiliary material for industrial manufacturing, aluminum foil paper is mainly used in packaging protection, daily necessities, construction, etc. It can be qualitatively guaranteed to be shading, not falling, opaque, non-polluting, and cheap. For high-grade cigarettes, candy, insulation materials and other moisture-proof and decorative use. A layer of aluminum foil is attached to the surface of the glass fiber insulation cotton, which has a great effect on the waterproof performance of the insulation cotton.

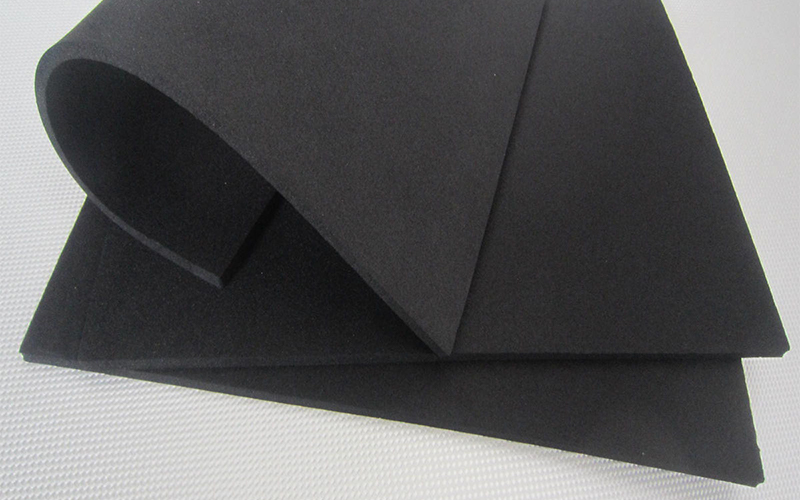

Rubber-plastic sound-absorbing cotton: Rubber-plastic sound-absorbing cotton is a polyethylene high-foaming product, and is also a new and widely used sound-insulating, waterproof and sound-absorbing material with low density, low thermal retention coefficient, good flexibility, anti-corrosion, and aging resistance. , heat preservation, sound absorption, shockproof performance, widely used in buildings, hotels, apartments, shopping malls, hotels, hospitals, schools, building walls, central air conditioning, transportation, KTV, ships, electrical, chemical, pharmaceutical, etc., almost applicable For any building or equipment that needs thermal insulation, heat absorption and shock resistance.

Rock wool insulation board: Rock wool board is a new type of thermal insulation, flame insulation and sound absorption material, which has the characteristics of light weight, small thermal conductivity, heat absorption and non-combustibility.

The above three sound-absorbing materials are the materials we often cut, and they are also the most widely used materials in the industry. Using our sound-absorbing panel cutting machine can not only cut a variety of special-shaped patterns, but also ensure the cutting accuracy.

If there is anything else you want to know, please contact us in time, we will answer you as soon as possible!

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/