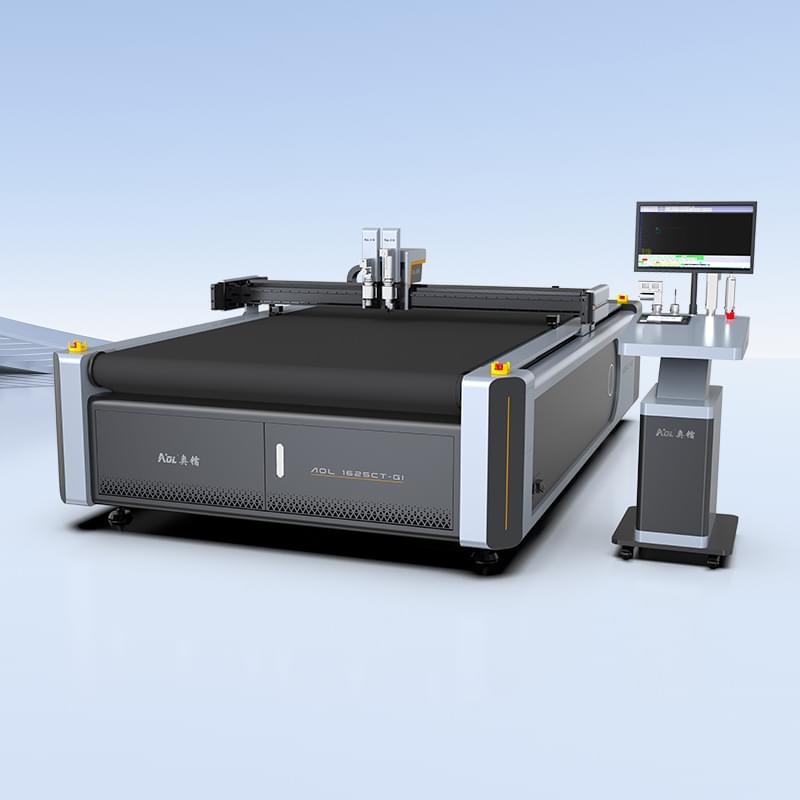

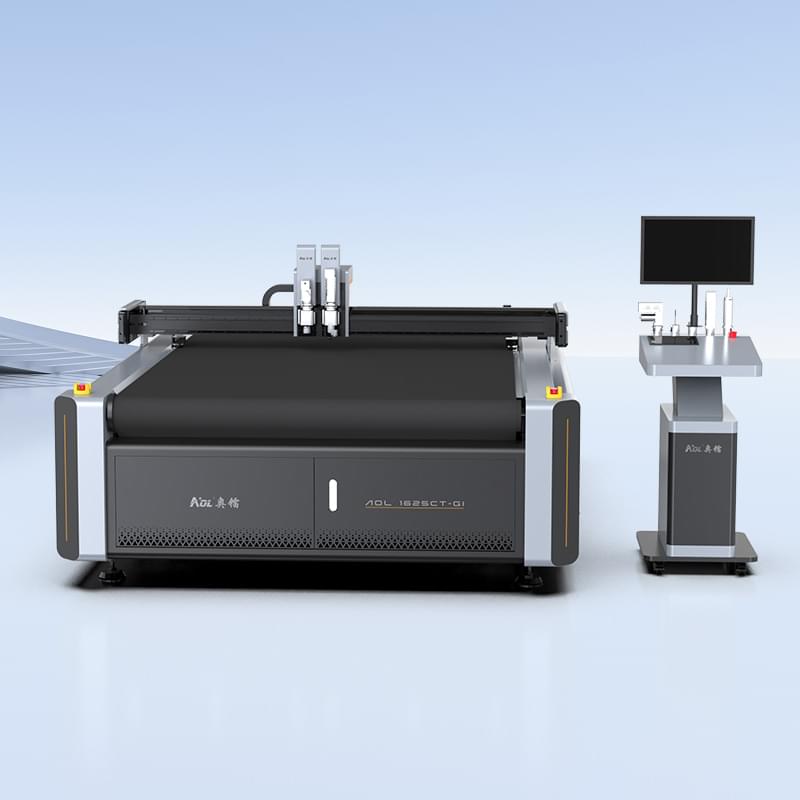

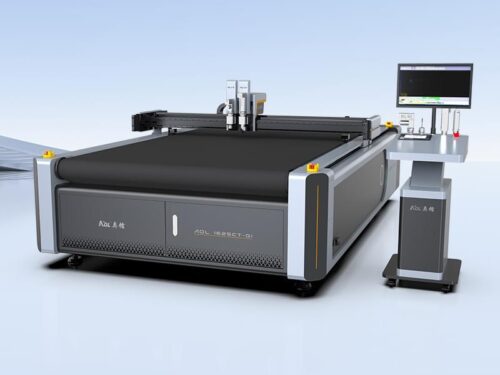

Application of High Quality Car Seat Cover Machine

Cutable materials:Foam compound, XPE, EVA, fabric carpet, imitation leather, leather, cloth etc.

Applicable Industry: Automotive interior, composite materials, seal gasket, sports goods, safa fabric etc.

In the field of automotive interiors, the materials that the High Quality Car Seat Cover Machine can cut, include various materials of car seat covers, car mats, trunk mats, reflective mats, etc.

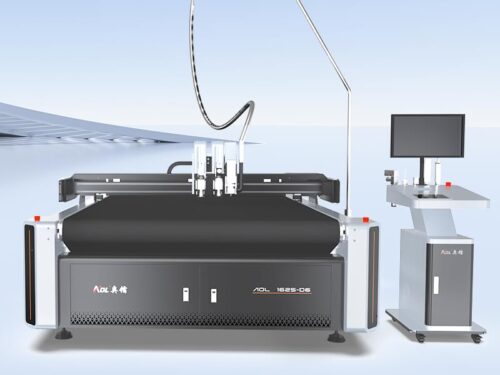

Specifications of AOL Automatic Car Seat Cover Mat Cutting Machine:

ADVANTAGES

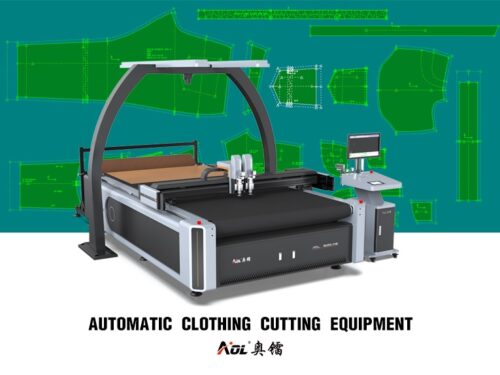

2.High efficiency: don’t need any die mould, or die mould cutting machine, this machine can press mark, cutting and moulding on soft material such as leather, carton etc. Save much labor and cost.

3.Low cost: one machine can do design, cutting instead of manual design and cutting, save labor, and materialSoftware advantage of High Quality Car Seat Cover Machine1.car seat cover cutting machine used software was developed by AOL itself. The software is imported with one key, simple and easy to operate, and ordinary workers can master it in 2 hours.2.Adopt a new super discharge engine. The discharge speed is 5 times the previous. Material utilization rate has also increased by more than 10%3.The fuselage adopts unique multi-zone technology. Usually 4 zones are needed, and the adsorption capacity is increased by more than 5 times. It is also possible to add more partitions according to customer needs, improve the adsorption capacity of small pieces of material.The user of Aol High Quality Car Seat Cover Machine, can also place the irregular material into the projection area for the alignment cutting, which greatly improves the utilization of the material.

OUR SERVICE

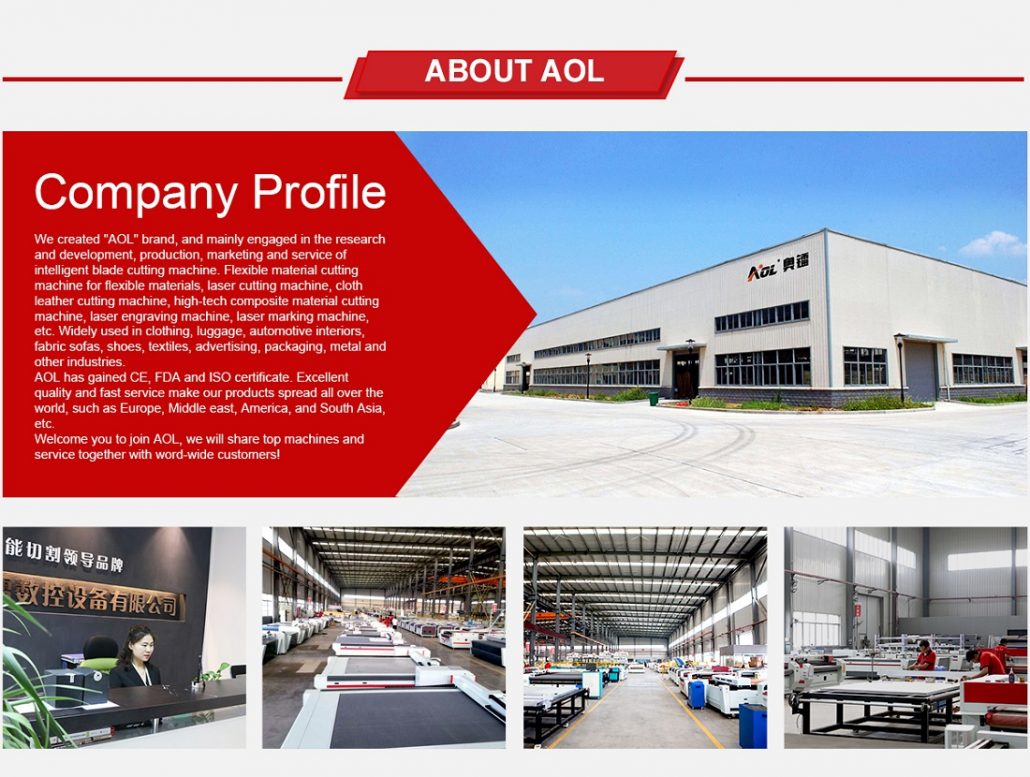

- Foreign trade practitioners with 12 years of experience specialize in docking related orders with customers

- Electricians and fitters with 30 years of experience instruct and participate in the installation of the machine

- AOL invests millions of research and development funds every year to improve machine performance and develop new products

- Hot sales in more than 40 countries around the world, and praised by customers, the repurchase rate is as high as 40%

- Currently, China’s only manufacturer of cutting machines that promises a three-year warranty

Answer: Film packaging+wooden case. Fumigation-free plywood case is also available.Question: How to operate this machine ?

Answer: We can provide operating video, user manual or telephone calls to help you. All these is written or speaking in English at present. On site service is also available.

There is no complicate operation nor special requirement for operator, operating is easy.Question: What’s the warranty policy?

Answer: Standard warranty is 12 month upon delivery.Question: What is the shipping cost from China to my country?

Answer: It depends on the distance between you and the sea port. We offer door to door service as long as you pay the relevant cost. For the shipping cost you can ask for our advice or from the freight forwarder.Question: How to judge if this cutting machine is suitable for me or not?

Answer: First, you should share something on the material (L*W*H,breathable or not) to be processed and other specific requirements, such as additional drawing function, punching holes function,etc. We will make first round judgement based on our experience. If necessary, we will make demo cutting for you, then we will share the video with you and discuss the possible solution.Question: Where is your factory located? How can I get there?

Answer: Our factory is based in jinan, shandong province,China. You can fly to beijing, jinan or qingdao. We can pick you up at the air station or train station.Question: Is there any after sales service?

Answer: We have integrated after sales service. Besides our own experienced engineers, we also offer local after sales service through the help of our agents. All this will make you convenient.

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

+86-531-88620680

+86-531-88620680

0086-18560162709

0086-18560162709

+86-531-88620680

+86-531-88620680

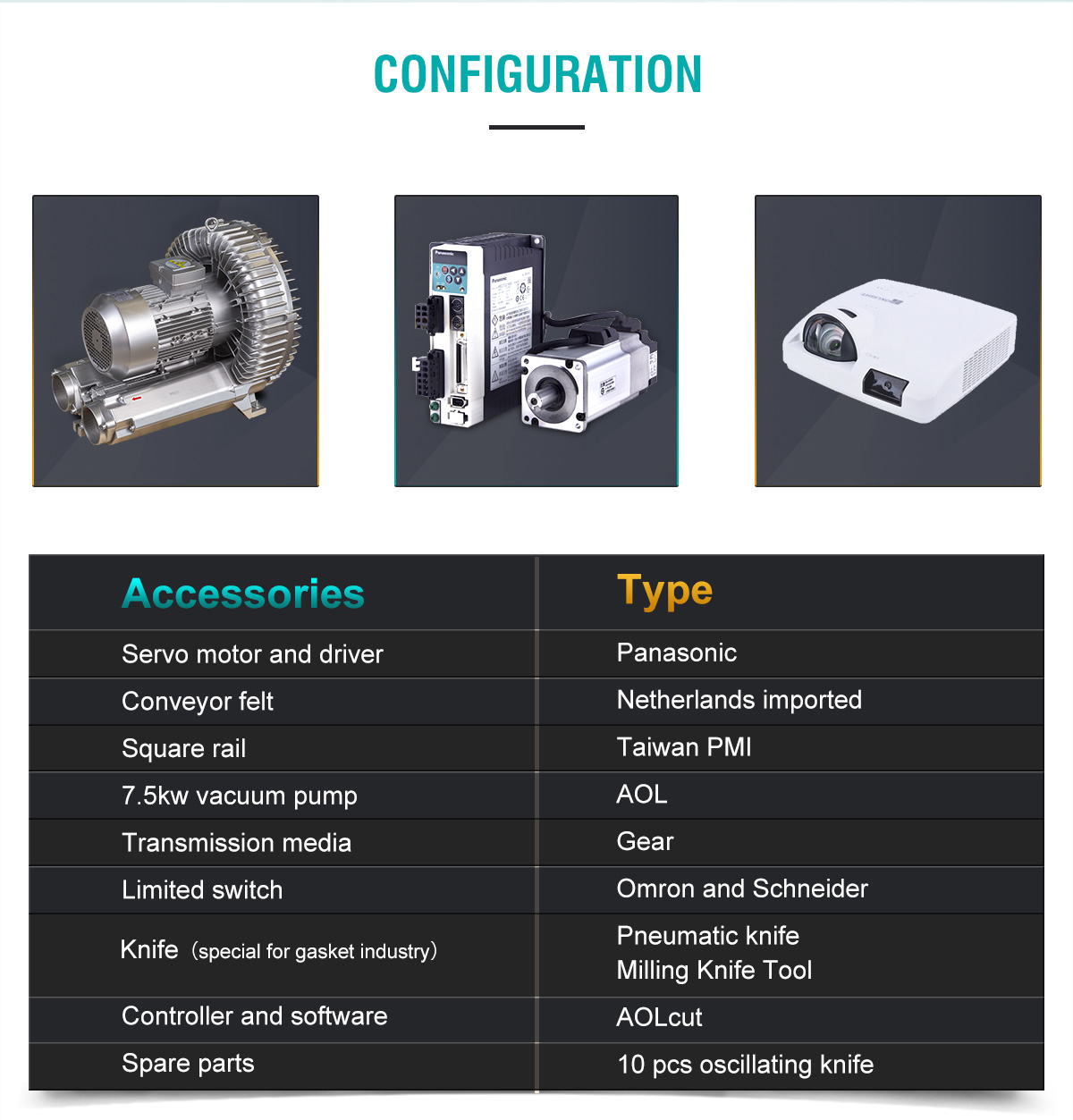

| Technical parameters / model | AOL-1625-GA6 | AOL-1825-ZS8 | AOL-2125-ZS10 | Accept special model customization | ||

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Reviews

There are no reviews yet.