What are the shortcomings of the leather cutting solutions in the market today and how to solve them?

1. Laser cutting produces a pungent smell of smoke, and it will cause a yellowing of the cutting material.

Laser cutting machine is a highly integrated equipment integrating light, machine and electricity. With high technology content, the emergence of laser cutting machine is a major turning point, improving production efficiency and enterprise efficiency. However, when the laser cutting machine cuts, it will produce a large smell of smoke, and the cut material will produce a paste, which not only pollutes the environment, but most importantly, it will cause harm to people’s health and affect the respiratory system.

2. Traditional cutting materials waste serious, increase production costs and reduce corporate profits.

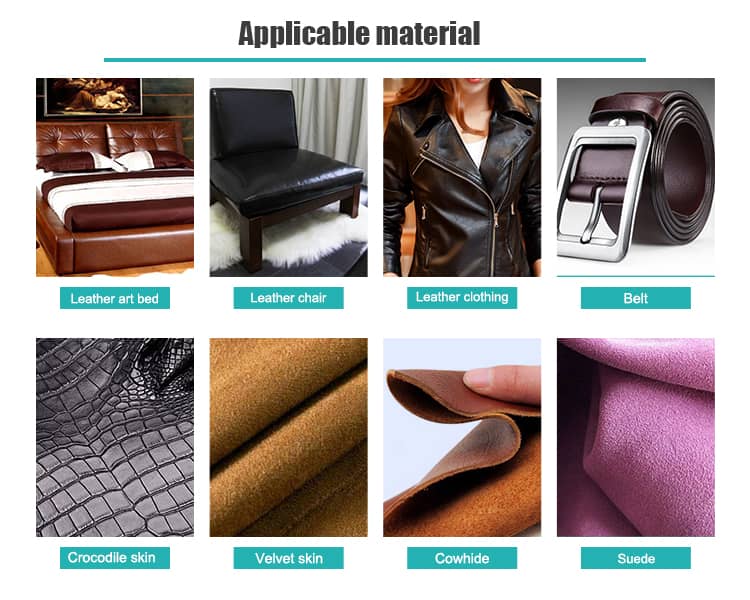

AOL launched a smart blade cutter for these problems.

A.In the precise cutting, it will not produce harmful gas and paste.

B.And added the over-cut optimization function: using AOL’s self-developed CAM software, optimizing tool overcutting, reducing material waste, improving material utilization, continuous cutting, intelligent typesetting.

C.Tool quick change module: AOL cutting machine equipment comes standard with tool quick change module, which has strong versatility, and it is quick and easy to change tools. Punch can also be done while cutting the leather!

For details of the machine, please click:https://www.aollaser.net/productshow-clothing_and_luggage_cutting_machine