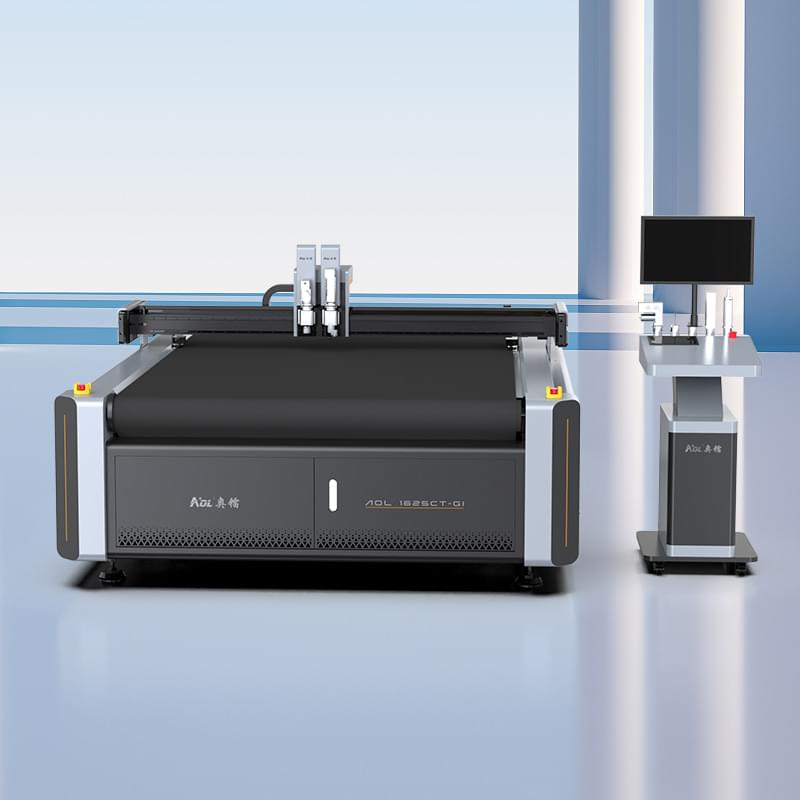

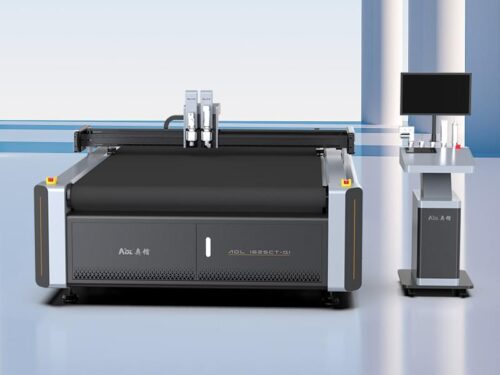

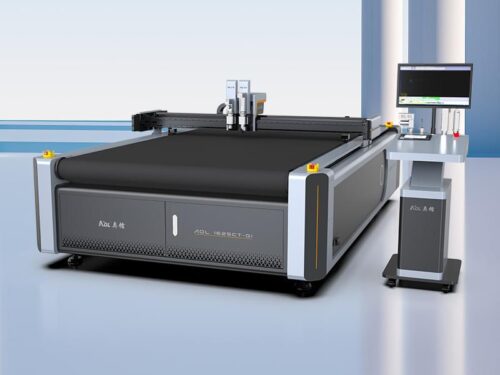

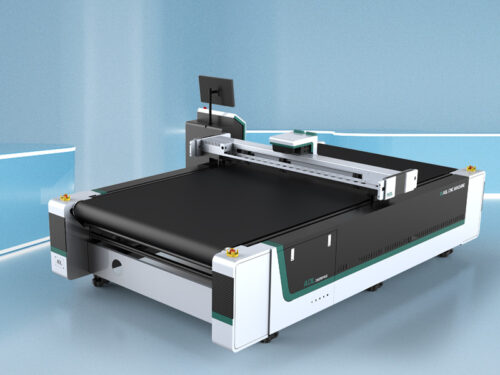

Product description

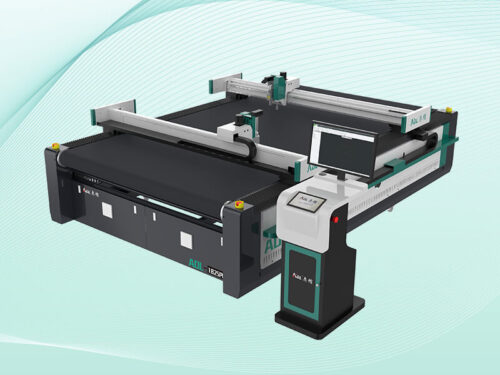

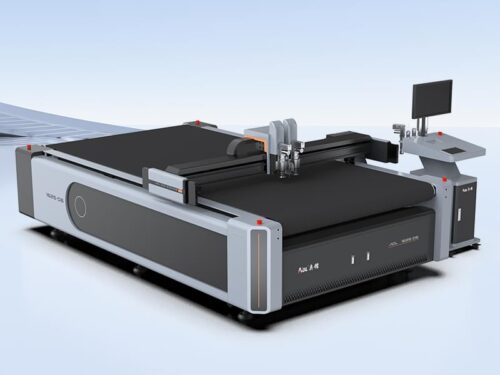

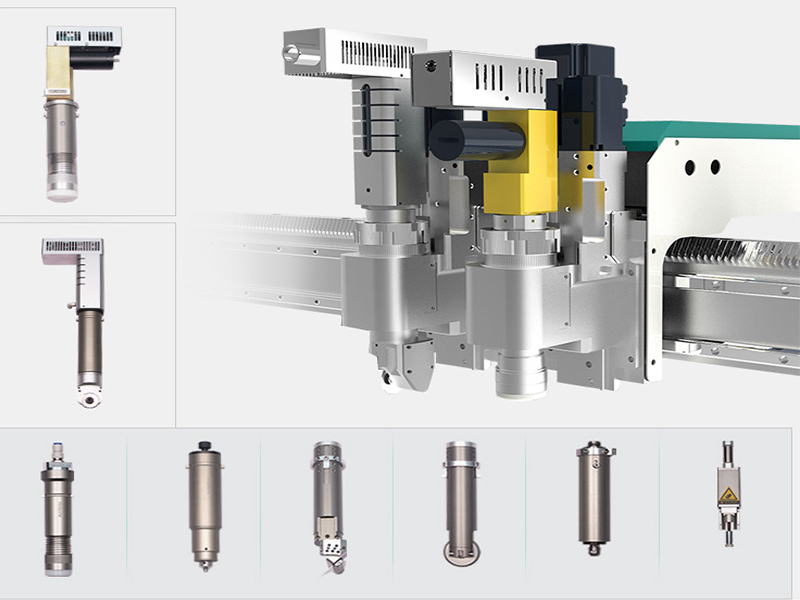

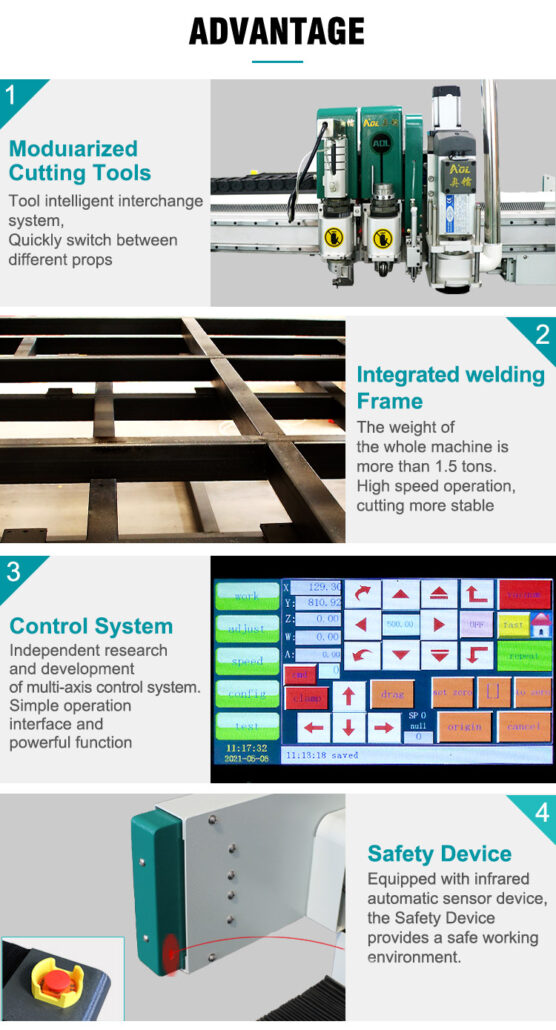

Multiple tool combinations

Can be equipped with different types of cutting tools to meet different thickness and hardness requirements

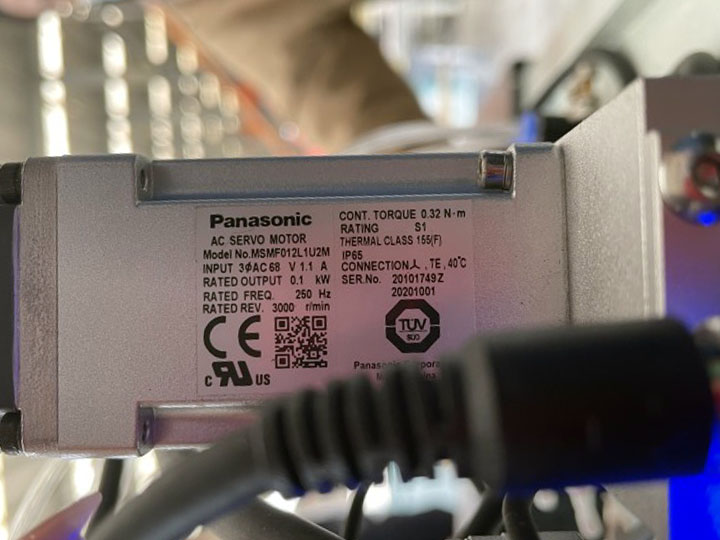

Imported servo motor

Imported servo motor, with large torque, durable and continuous power for foam board cutting.

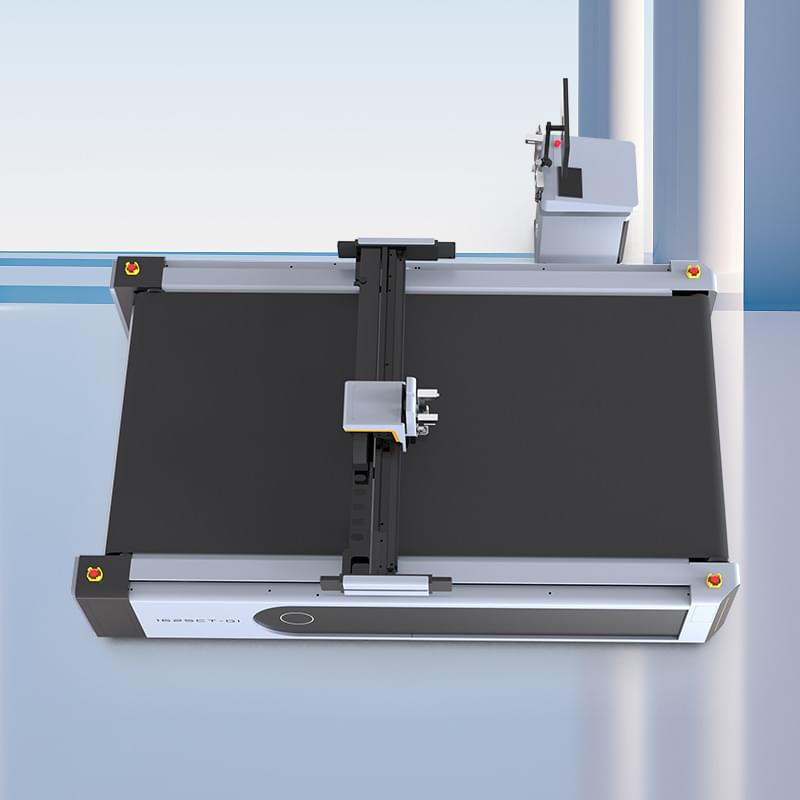

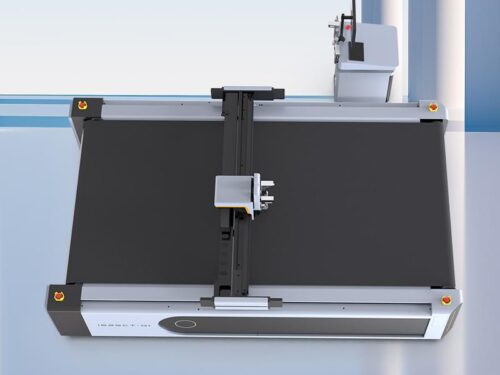

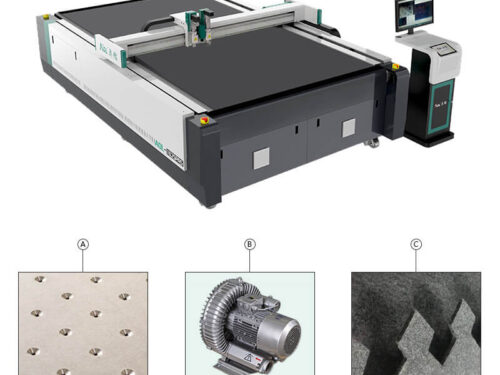

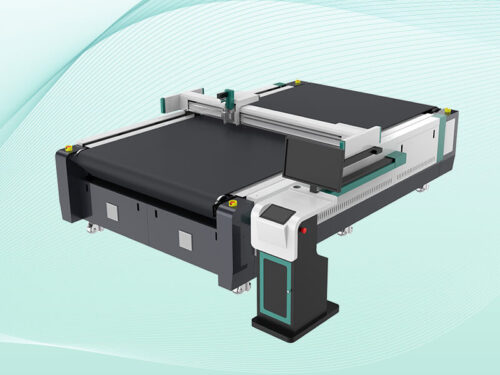

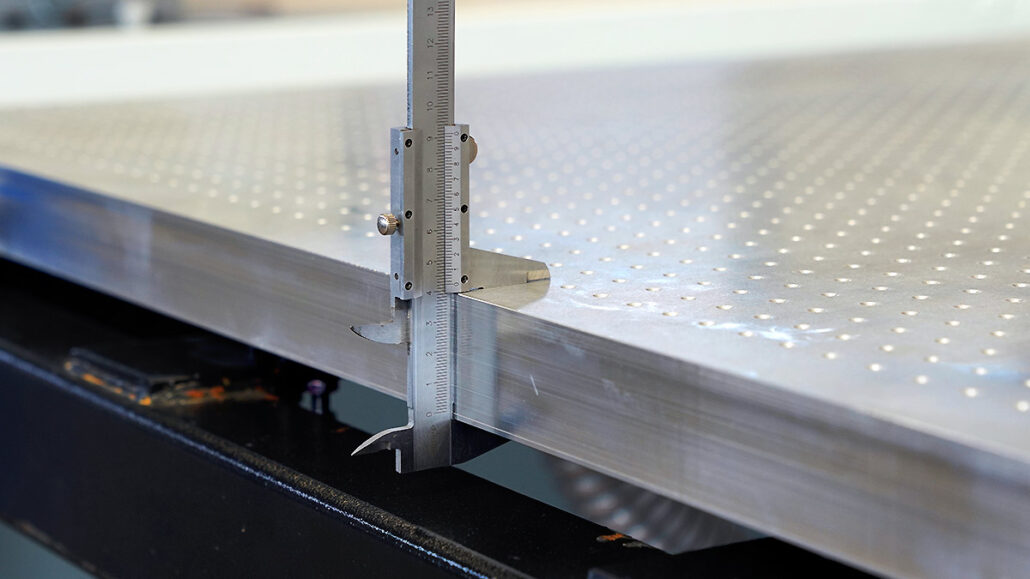

Vacuum adsorption platform

Optional zone adsorption, 8-16 adsorption zones. Following adsorption, strong suction holds the material to ensure accurate cutting data without deformation.

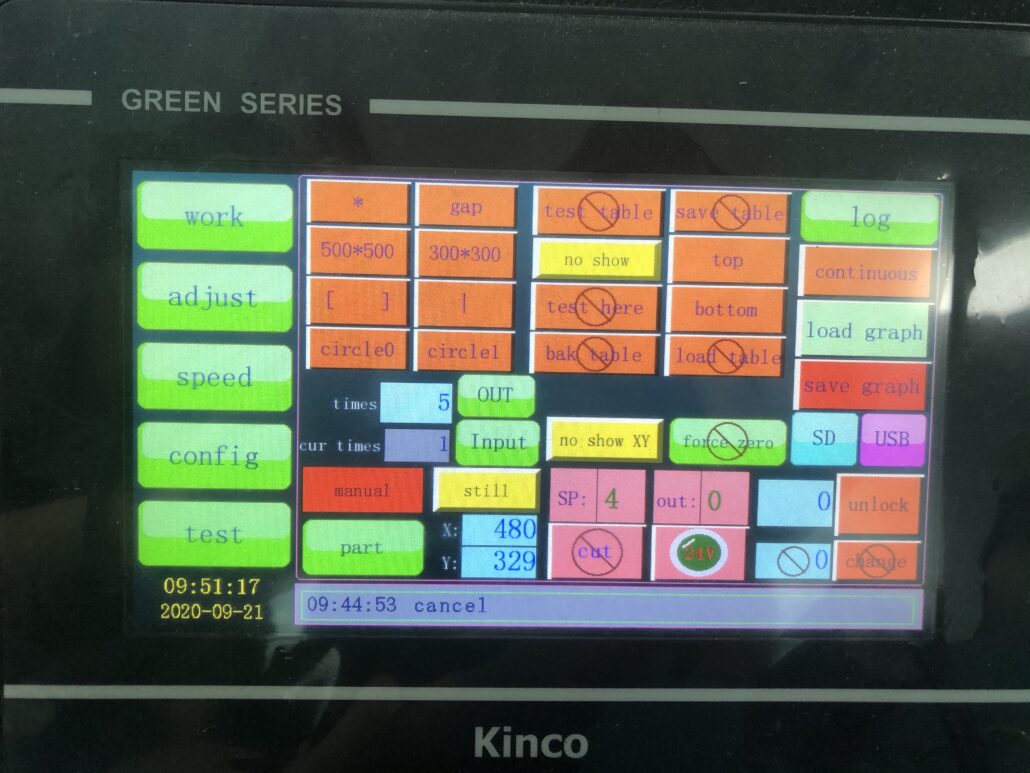

Touch screen operation panel

Color touch control panel, more intuitive operation interface, connect to the computer to directly accept data, set cutting depth and cutter head parameters, have a powerful database, support one-key retrieval.

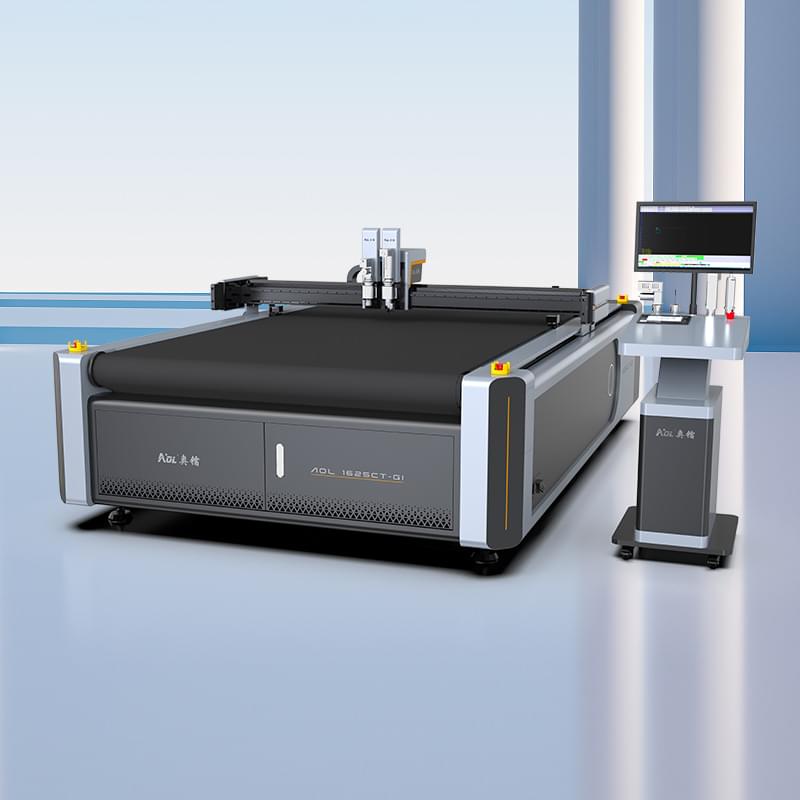

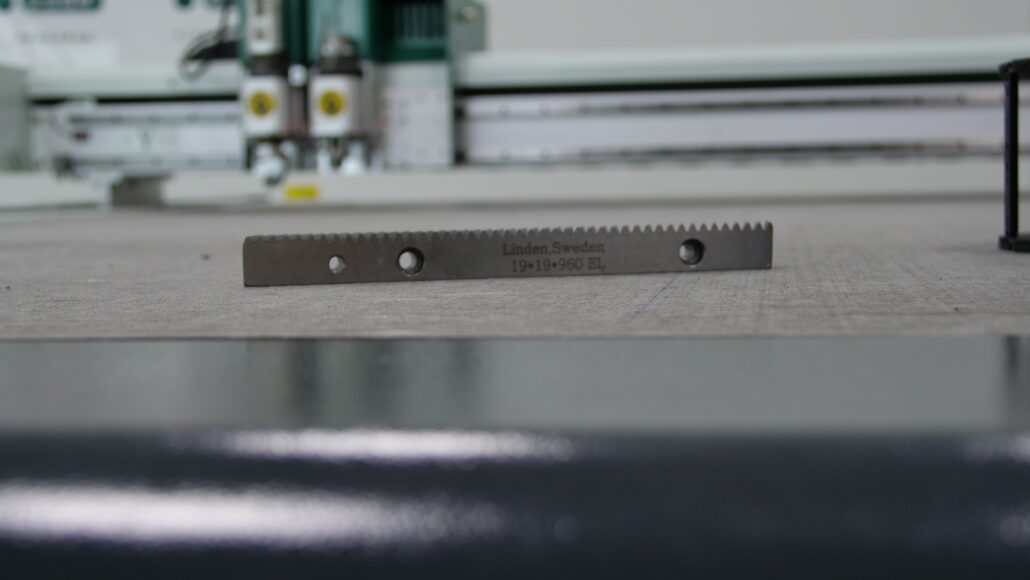

Precision rack drive

Servo rack drive mode, the Y axis is driven by double servo motors, with strong power and stable performance.

Integral welding bed

The bed adopts welding process, aluminum alloy body frame, anti-corrosion and high hardness, high temperature heat treatment, milling machine finishing, stable and durable

rack motion

The beam of the machine adopts an all-aluminum structure, which reduces the weight of the beam and ensures the rapid movement of the machine. The rack is used for movement, stable movement, and long use time.

Taiwan drive rail

Adopt Taiwan’s high-quality transmission guide, with its own lubrication system, low friction resistance, to ensure high-speed and smooth cutting.

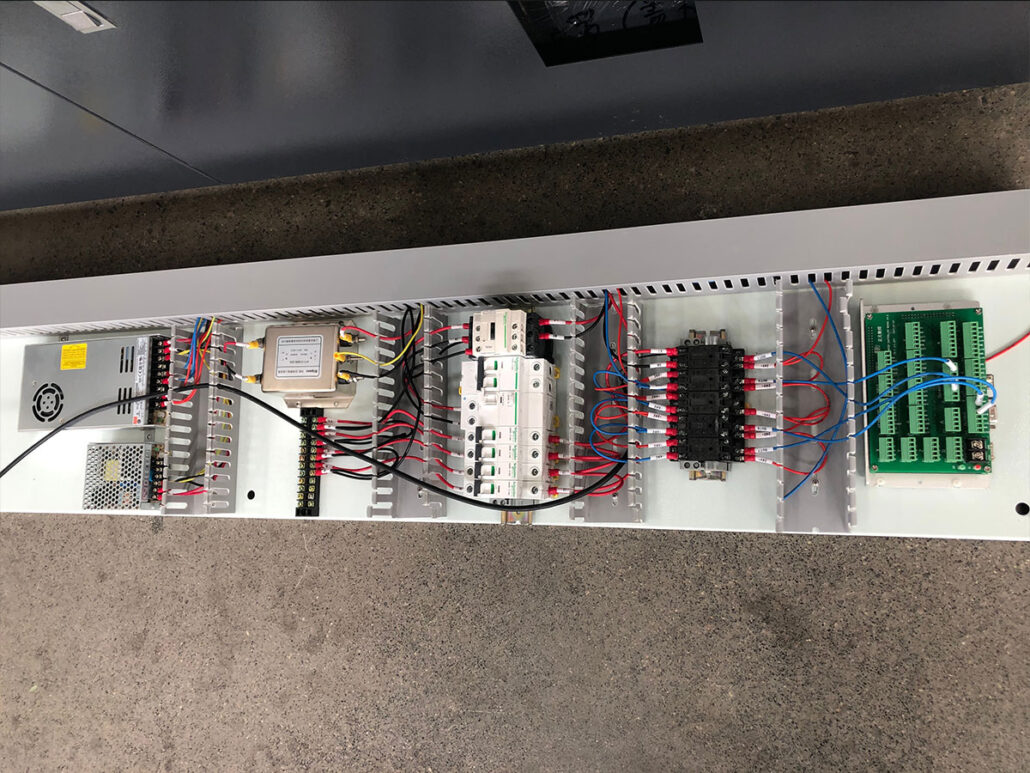

Scientific electrical control system

The wiring is scientific and reasonable, and each line has a corresponding mark, which is convenient for the maintenance and maintenance of the machine. All electrical components come standard with Schneider and top brand quality.

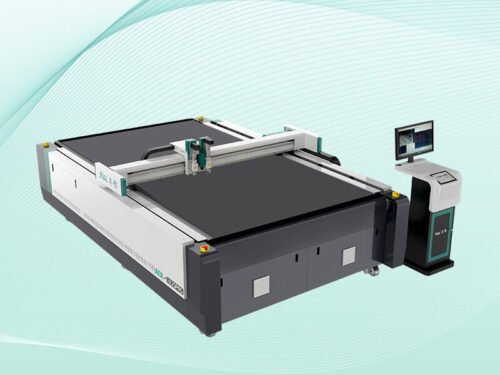

Vibrating knife gasket cutting machine with CE/ISO/FDAcertificate

Vibrating knife sealing gasket cutting machine cutting advantages

1. Overcut optimization function: Using AOL’s self-developed CAM software to systematically optimize the physical overcut phenomenon of the tool, restore the graphic outline to the greatest extent, and bring customers the perfect cutting effect

2.Intelligent table compensation function: The flatness of the table is detected by a high-precision distance detector, and the plane is corrected in real time through the software to avoid inconsistent cutting depth, effectively protect the felt, and achieve a perfect cutting effect.

3. Automatic positioning and sleeve cutting function: obtain the pattern deformation law by identifying the marking points, and optimize the original contour pattern according to the deformation amount for precise sleeve cutting

4. Automatic tool setting function: fast and simple automatic tool setting system, using fiber laser sensor to accurately detect tools, improve tool setting efficiency

5. Tool quick change module: simple, flexible and efficient diversified tools, which can replace different tools according to different cutting materials, one machine is multi-purpose

6. Multi-task and efficient cycle cutting, intelligent adsorption configuration

Parameter of Vibrating knife gasket cutting machine

| TECHNICAL PARAMETERS / MODEL | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | ACCEPTING SPECIAL-SHAPED CUSTOMIZATION |

|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500mm | |

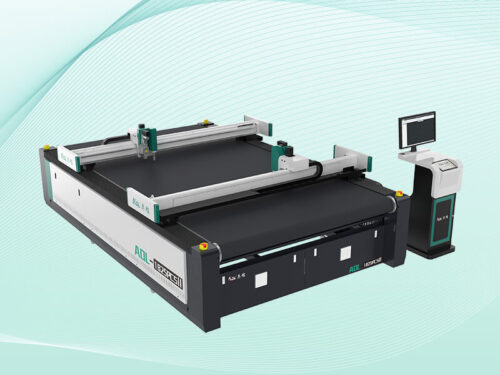

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, semi-cutting cutting, full cutting cutting, camera positioning cutting, edge finding cutting, acrylic milling cutter, cursor positioning, line marking, indentation knife, V-groove knife, etc. | |||

| safety devices | Infrared sensing, safe and reliable | |||

| Cutting speed | 200-2000mm/s | |||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||

| Applicable materials | Various KT boards, Chevron boards, honeycomb boards, car stickers, adhesives, photo frame paper, gray board paper, corrugated paper, EPE foam, PVC board, acrylic sheet, thick foam, etc. | |||

| Material fixing method | Vacuum partition adsorption | |||

| Transmission port | Network port | |||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||

| rated power | 11kw | |||

| Rated voltage | 380V±10%/220V±10%Optional | |||

| Control System | Chinese and English LCD touch screen | |||

| Operating environment | Temperature 0-40°C Humidity 20%-80%RH | |||

| software | Automatic nesting software, camera positioning, large format camera system | |||

| Support file format | AI、PLT、DXF、CDR etc. | |||

Vibrating Knife Gasket Cutting Machine application industry

Gaskets are an industry with a wide range of designs and many types of materials. Common materials include graphite gaskets, asbestos gaskets, rubber gaskets, latex gaskets, cork gaskets, etc. The cutting of gaskets usually uses a punch, before cutting. It is necessary to open the mold, and then perform extrusion cutting. This cutting method is easy to cause the problem of inconsistent upper and lower accuracy of the material, which will cause a certain image for the sealing of the material. In addition, punch cutting will generate the cost of the mold pair. If it is a small batch In the production of gaskets, the cost of molds is often higher than the cost of materials, so a vibrating knife cutting machine with high precision and data import cutting is required.

If there are other industries, all non-metallic materials are cut by AOL CNC cutting machines, as follows:

1. Packaging industry: corrugated cardboard, honeycomb cardboard, kraft paper and other packaging boxes (cutting, creasing, dotted cutting, scribing marks)

2. Advertising industry: stickers, labels, PP paper, flags, inkjet cloth, light boxes, KT boards

3. Automotive interior industry: car interior dimensions of various models and materials such as leather and artificial leather (with a multi-model database)

4. Composite materials: EVA, EPE, PVC, soft glass, fiber products (glass fiber, carbon fiber, etc.), thermal insulation cotton, sound insulation board, rubber, etc.

5. Textile industry: clothing fabrics of various materials, matching materials for suits, home textiles (curtains, sofas, tablecloths, etc.)

6. Leather industry: genuine leather materials, artificial leather materials, composite leather materials, etc. (cutting, marking)

7. Gasket industry: gaskets of various materials (asbestos, non-asbestos, rubber), PTFE (special-shaped, small-area cutting)

8. Carpet industry: various types of carpets, silk circle carpets, diatom mud carpets, etc., carpets for various environments (standard or special-shaped cutting)

-1.jpg)

AOL SERVICE

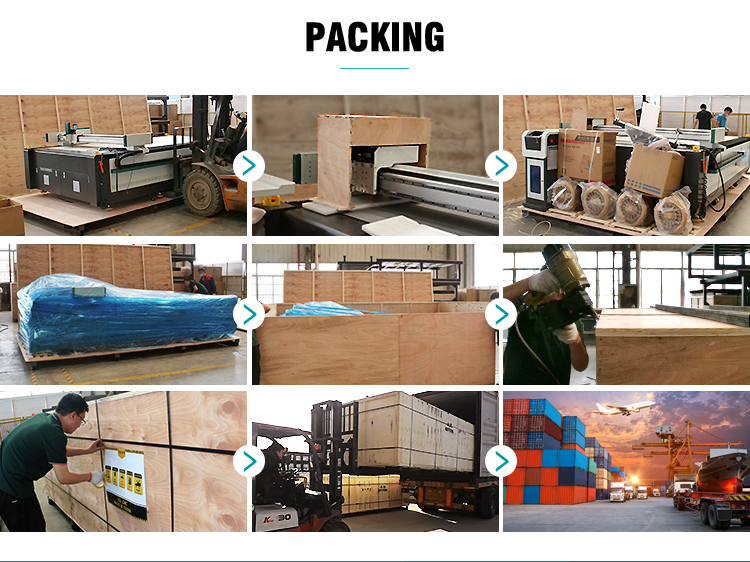

Packing details of Vibrating knife gasket cutting machine

Transportation

After sale service

Eight reasons to AOL CNC cutting machine

1. Advanced brand: ten years of professional CNC blades

2. R & D advantages: a number of patented technologies, so that the company has a deep deposit

3. Quality assurance: all products have passed European CE certification. US FDA certification

4. High-quality materials: All CNC cutting machine accessories are selected from industry-leading brands.

5. Advanced technology: starting from Germany, foreign advanced technology, technical support

6. High efficiency: implement one-to-one service to improve the efficiency of corporate feedback

7. Personalized customization: With the development and design functions, customers can do whatever they want

8. After-sales service: provide three-year warranty service and 24-hour online solutions.

AOL company info

Welcome to join AOL, we will share top-level machines and services with customers all over the world.

-1.jpg)

Media information

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/