Meeting individual customer needs is the key to success. Choosing the right tools is essential to improve efficiency, reduce costs and provide high-quality customized products.

This article covers everything you need to know about cutting polyester fiber panels, from the advantages of oscillating knife machines to tips for choosing the right manufacturer and using the machine effectively. Whether you are new to the industry or an experienced person, this article will help you make more informed decisions and grow your business.

How to make sound-absorbing board decorative products

Polyester acoustic panels are a lightweight, durable and versatile acoustic treatment material. Made from compressed polyester fibers, they effectively reduce noise and reverberation in a space.

How are polyester fiber sound-absorbing products made?

The production process includes cutting and slotting the panels into specific shapes and designs. Advanced cutting equipment ensures high precision and efficiency, easily meeting various design requirements.

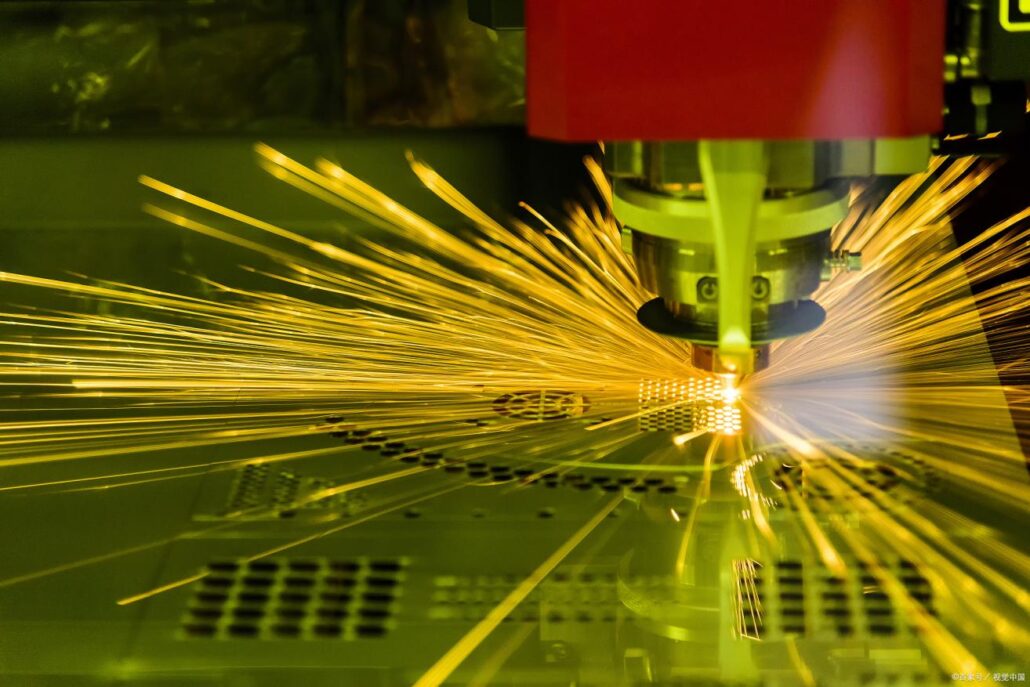

Why is laser cutting not suitable for polyester fiberboard?

Laser cutting generates heat which may burn or melt the material. Produce smoke and odors. Result in uneven or hardened edges.

Modern designs require complex shapes, intricate grooves and 3D effects. Traditional cutting methods often fail to meet these demands, resulting in serious market losses.

Meeting design demands is essential to staying competitive. Investing in advanced cutting technology ensures you retain customers, increase profits and stay ahead of the market.

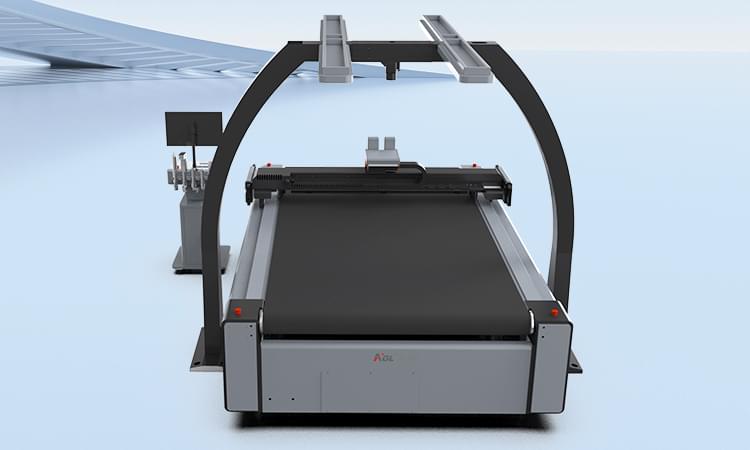

A better cutting solution is an oscillating knife cutter!

What is an oscillating knife cutter?

CNC machines that use vibrating blades for cold, precise cutting without damaging the material.

The benefits of using a vibrating knife cutting machine are:

High efficiency and high precision.

Dust-free, environmentally friendly process.

Suitable for complex designs and different thicknesses.

Reduced reliance on labor and improved production quality.

Features and advantages of polyester fiber sound-absorbing board cutting machine:

1. High-speed cutting (300-400mm/s)

2. Clean edges and no material damage.

3. Easy-to-use custom software.

4. Support V-grooving, straight cutting and arc design.

There are mainly the following types:

Single-head vibration knife cutting machine

Dual-head machine can cut and groove at the same time. With CCD recognition system, it can meet the precise cutting of the outline of the printed sound-absorbing board pattern.

Parameters of polyester fiber sound-absorbing board cutting machine:

| Technical parameters | AOL-1625, AOL-1825, |

|---|---|

| Effective working area | 1600*2500MM, 1800*2500MM |

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

| Tools | Universal Drawing Tool, Creasing Wheel Tool |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.05mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

| Cutting material | Paperboard, grey board, KT board, pvc foam board, honeycomb board, car sticker, lamp piece, PP Adhesive material, printing cloth, banner cloth, all kinds of corrugated board, EPE foam, EVA, PVC board, acrylic board, thick foam and so on |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

How to find a reliable manufacturer:

1. Check their website to see if they offer machines specifically recommended for polyester fiber acoustic panels.

2. Search online platforms Look for their presence on Alibaba, Google, or YouTube. A strong online presence indicates credibility and product availability.

3. Request a cut sample Visit their factory for a demonstration to confirm they have experience in your industry.

4. Evaluate after-sales support Make sure they offer training, technical support, and readily available spare parts.

How to choose a suitable cutting machine:

01. Material compatibility

Make sure the machine supports the thickness, density, and type of polyester panels you need to cut.

02. Tool configuration

Choose a machine equipped with basic tools such as oscillating knives and bevel knives to meet different cutting and grooving needs.

03. Cutting efficiency and accuracy

Look for a machine with high cutting speed and consistent accuracy, especially for complex designs and intricate grooves.

04. Customization and flexibility

Confirm whether the machine’s cutting area or tool settings can be customized to meet your specific production requirements.

05. Ease of use

Choose a machine with user-friendly software and simple operation to save training time and increase productivity.

06. After-sales support

Make sure the manufacturer provides strong technical support, spare parts availability, and clear warranty terms.

07. Cost and manufacturer reputation

Choose a machine that is value for money, backed by a trusted supplier, and has positive reviews and relevant industry experience.

Essential accessories for oscillating knife cutting machines:

Blades: The primary cutting tool; replace regularly to ensure clean and accurate cuts.

Felt: Protects the cutting table and provides a stable surface for the material during cutting.

Spare tools: Such as extra blades or cutting heads to avoid downtime during production.

Belts and limit switches: Essential for the movement and positioning of the machine; keep spares to maintain smooth operation.

Spare screws and small parts: Essential for quick repairs or replacement of small machine parts.

Installation tools: Tools used to set up and maintain the machine, such as wrenches and screwdrivers.

Guide slides: Ensure smooth movement of the cutting head; check and replace as needed to maintain accuracy.

The polyester fiber acoustic panel cutting machine is an essential tool for producing high-quality acoustic and decorative products. With the right machine, tools and maintenance methods, you can achieve efficient and precise results, making it a valuable investment for your business.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/