There are many types of carbon fiber woven cloth, which are divided into carbon fiber unidirectional cloth, carbon fiber satin cloth, carbon fiber laminated cloth, carbon fiber plain weave, carbon fiber twill cloth, etc. The toughness of carbon fiber woven cloth is great, and it is difficult to cut manually. The efficiency is low and the phenomenon of loose edges is easy to occur. The vibrating knife carbon fiber woven cloth cutting machine described in this article is suitable for cutting all fiber cloth materials. The cutting effect is good, the edges are not scattered, and the utilization rate is high.

Features of carbon fiber fabric:

1. High strength, low density, thin thickness, basically does not increase the self-weight and section size of the reinforcement member..

2. It has a wide range of applications and is widely used in the reinforcement and repair of various structural types and structural shapes such as buildings, bridges, tunnels, etc., as well as seismic reinforcement and structural reinforcement of joints.

3. The construction is convenient, no need for large equipment, no wet work, no need for hot work, no need for on-site fixed facilities, less space occupied by the implementation of state engineering, and high construction efficiency.

4. High durability, because it will not rust, it is very suitable for use in high acid, alkali, salt and atmospheric corrosion environments.

Advantages of carbon fiber woven cloth cutting machine:

1. Save manpower and material resources, without changing material properties, a carbon fiber woven cloth cutting machine can replace 4-6 laborers

2. Automatic loading and unloading for cutting, the running speed can reach 2000mm/s

3. The intelligent automatic discharge system of the system can improve the material utilization rate by more than 15%

4. The cutting is not loose, the error rate is low, and nearly one million material costs can be saved every year

5. Professional R&D team can provide assembly line supporting solutions

Application fields of carbon fiber woven cloth cutting machine:

1. Aerospace: fuselage, rudder, rocket engine casing, missile diffuser, solar panels, etc.

2. Sports equipment: auto parts, motorcycle parts, fishing rods, baseball bats, skis, speedboats, badminton rackets, etc.

3. Industry: engine parts, fan blades, drive shafts, and electrical components, etc.

4. Fire protection: It is suitable for the production of special high-grade fireproof clothing for troops, firefighting, steel mills and so on.

5. Construction: the use load of the building is increased, the function of the project is changed, the material is aged, and the concrete strength level is lower than the design value

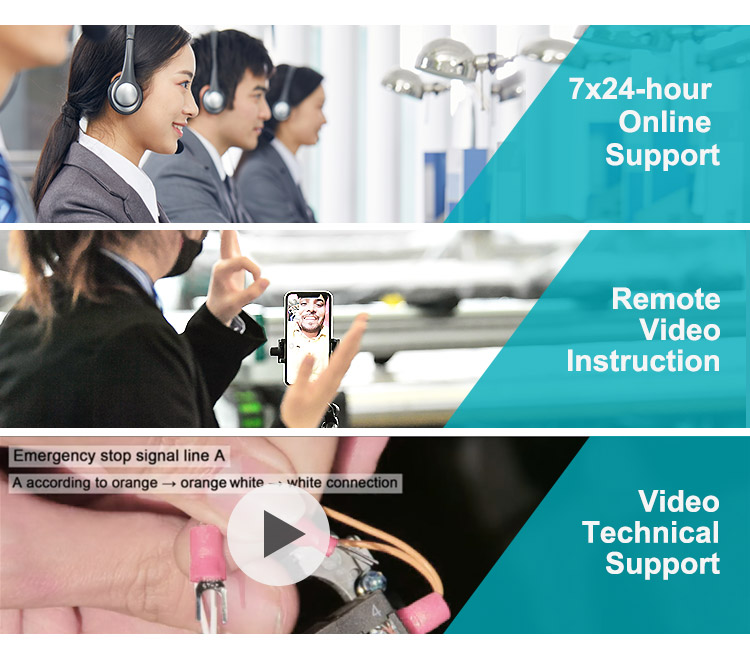

AOL service:

1) Three-year free warranty (except wearing parts), free inspection and maintenance of main parts.

2) Provide lifetime free technology upgrade service

3) Wearable parts (eg blades, bench covers) are always available at cost when needed.

4) Free operation training in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support is available when needed.

7) AOL accepts unreasonable returns within 7 days after receiving the goods.