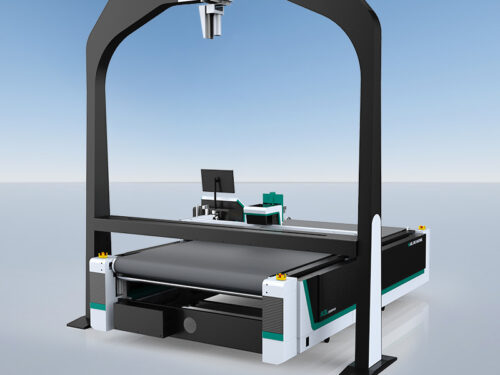

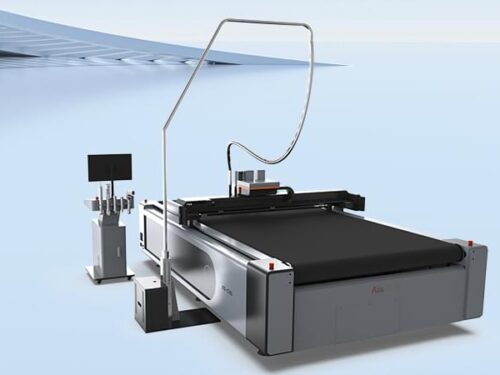

The PU leather vibrating cutter is a specialized piece of equipment used to cut synthetic leather or PU leather material. PU leather, also known as polyurethane leather or faux leather, has become a popular alternative to genuine leather due to its durability, affordability, and ease of maintenance. Cutting machines designed specifically for PU leather allow for precise and efficient cutting, making them an essential tool for industries such as upholstery, fashion, automotive, and accessories manufacturing.

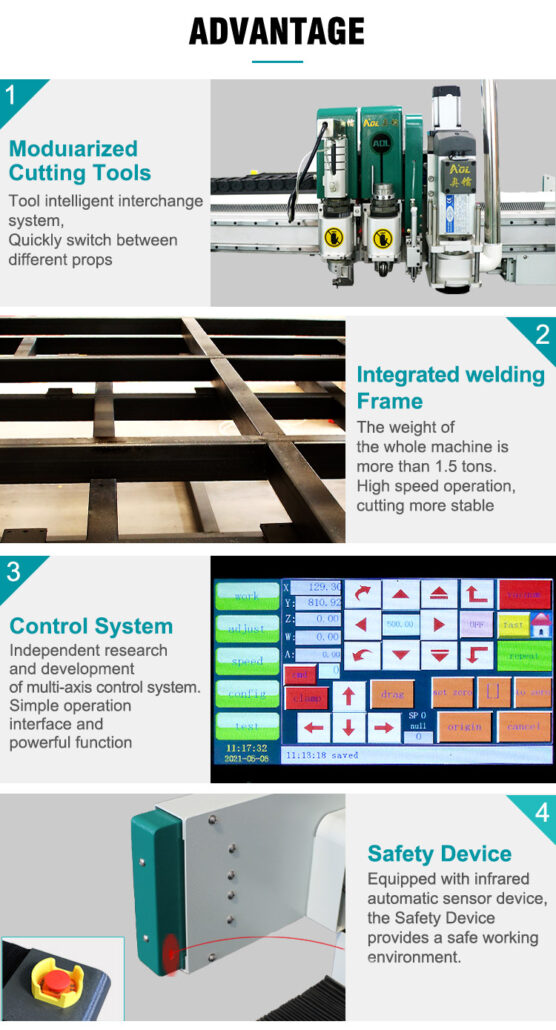

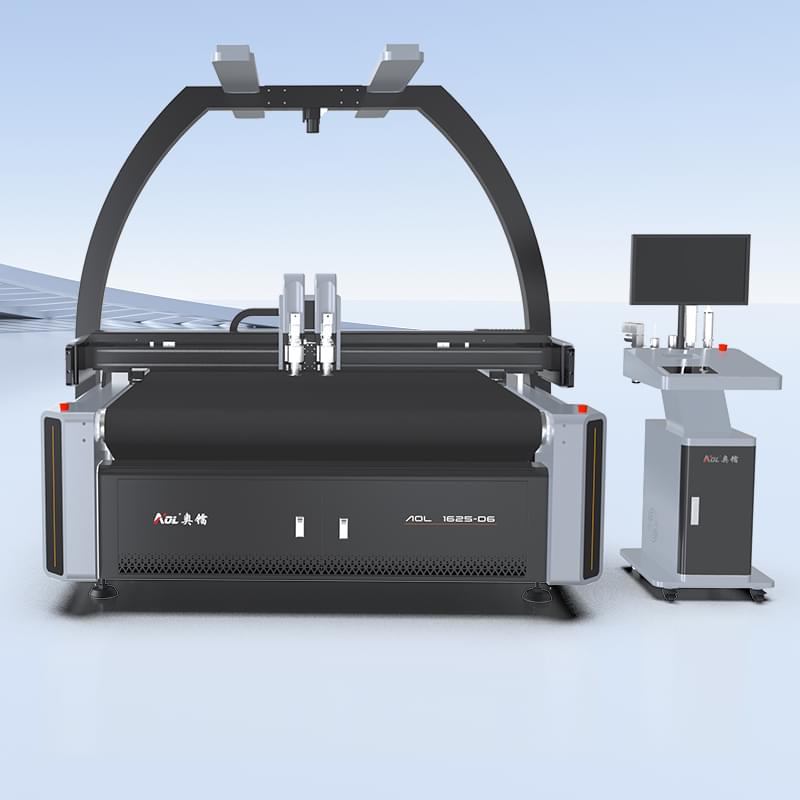

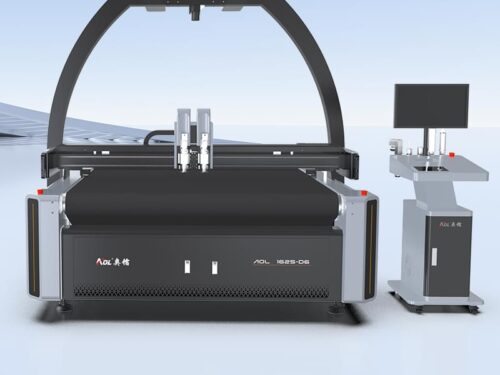

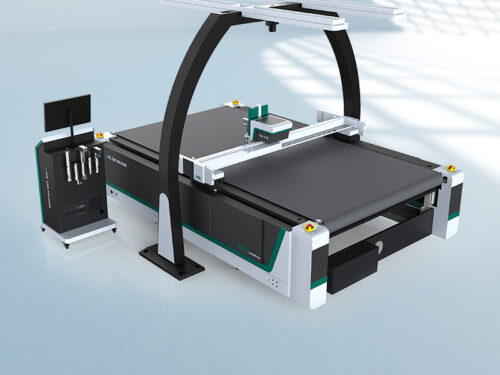

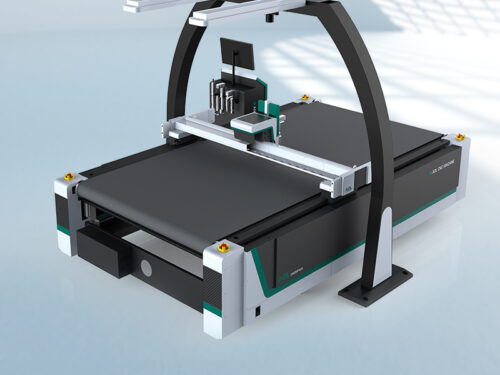

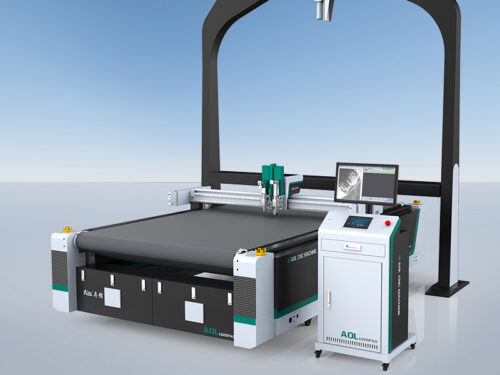

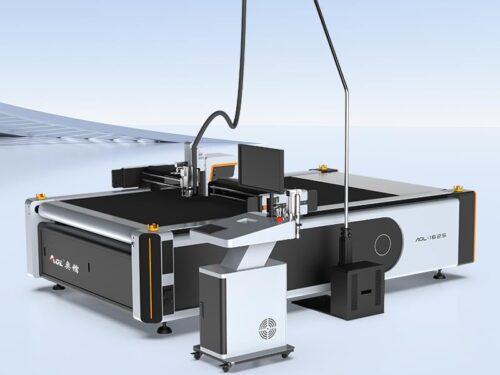

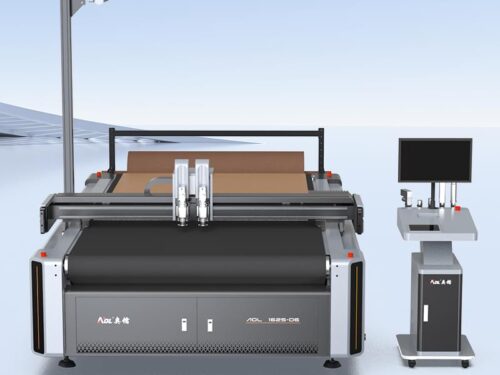

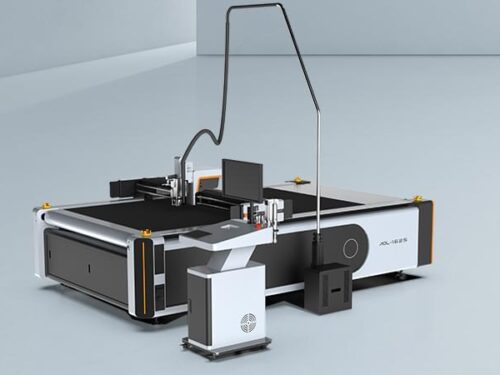

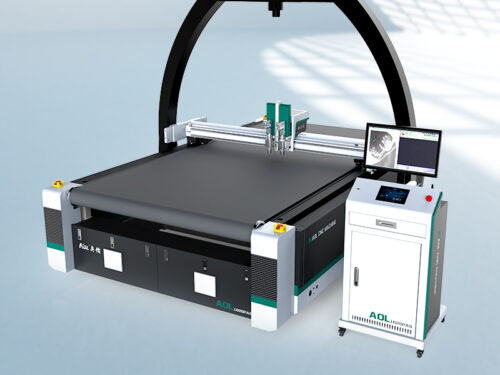

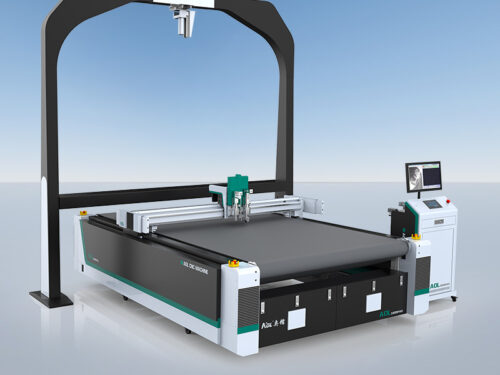

CNC Oscillating Knife Cutting Machine is a CNC cutting machine for high precision cutting of heavier flexible and semi-rigid materials. Equipped with multi-knife cutting head – Oscillating Knife, Bevel Knife, Circular Knife, Punching Knife, Milling Cutter and Marking Pen. Optional CCD camera and projector for more precise cutting.

Features of PU leather cutting machine

1. Cutting Mechanism: PU leather cutting machines employ various cutting mechanisms depending on the specific model. Common cutting methods include blade cutting, laser cutting, or a combination of the two. Blade cutting machines use a sharp blade to physically cut the PU leather, while laser cutting machines use a high-powered laser beam to vaporize or melt the material along the cutting path.

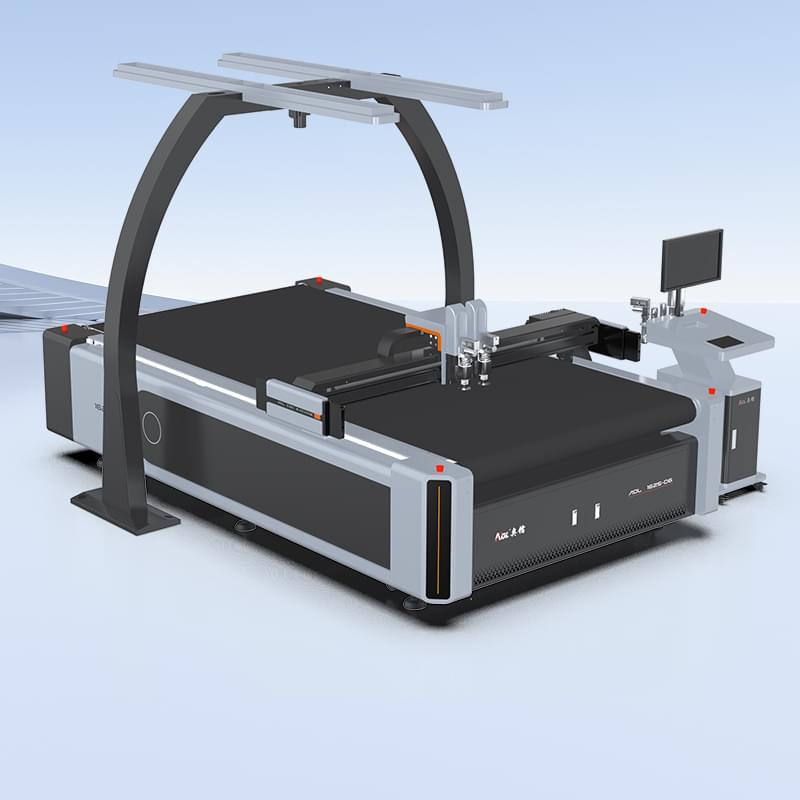

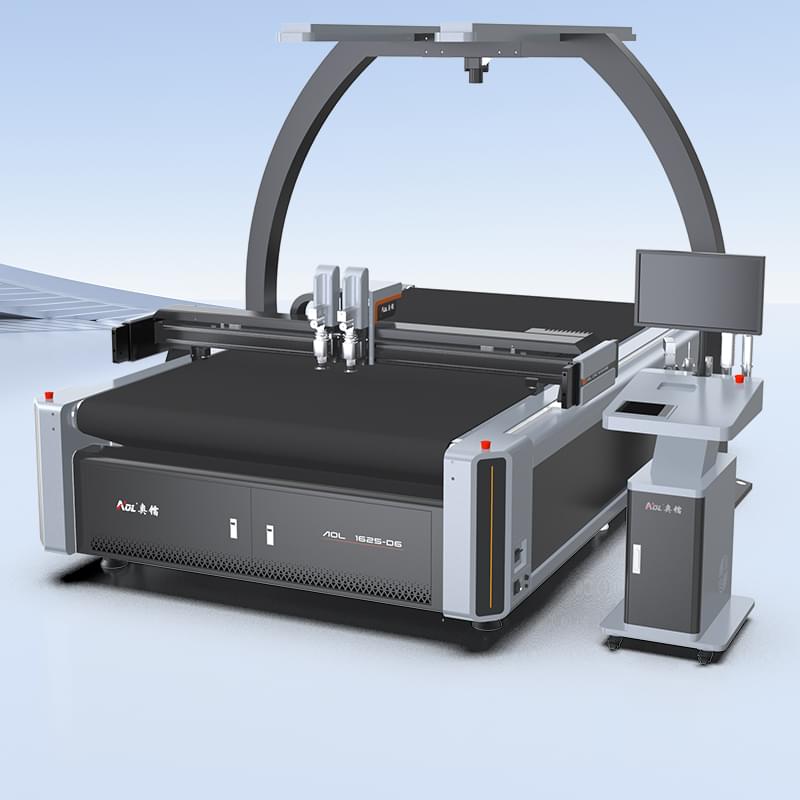

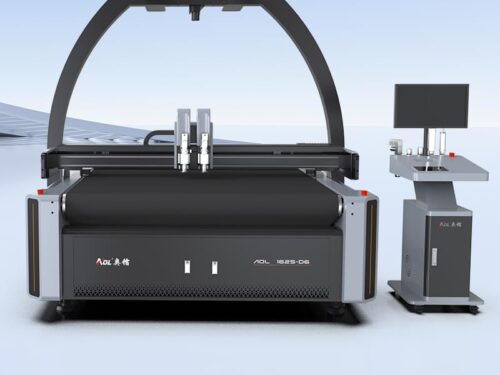

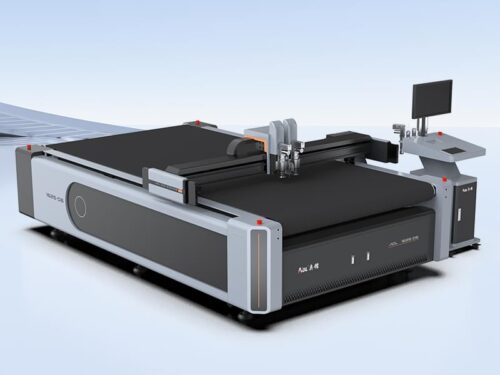

2. Precision and Accuracy: PU leather oscillating knife cutting machines are designed to provide precise and accurate cutting, ensuring clean edges and minimal material waste. The machines typically employ advanced control systems, including computer numerical control (CNC), to achieve high levels of cutting accuracy and repeatability.

3. Cutting Speed: PU leather cutting machines typically have high-speed cutting capabilities, which enables efficient production processes and increases productivity. Cutting speeds may vary depending on factors such as machine model, cutting method, and design complexity.

4. Leather oscillating knife cutting machines can handle a wide range of PU leather materials, including different thicknesses, textures, and finishes. They are suitable for cutting PU leather sheets, rolls, or custom patterns, making them suitable for a variety of applications.

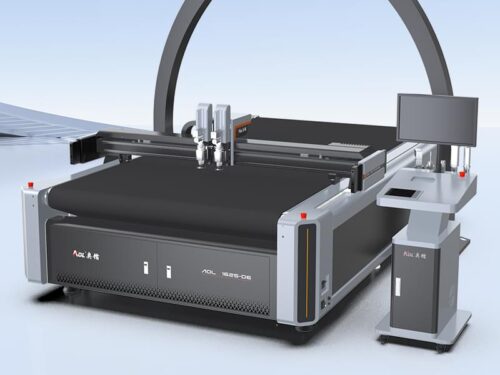

5. Automation and Software Integration: Some advanced PU leather cutting machines offer automation features and software integration. These machines may have automatic feeding systems, conveyors, or robotic arms to increase efficiency and productivity. Software integration allows for seamless design transfer and precise control of cutting patterns and shapes.

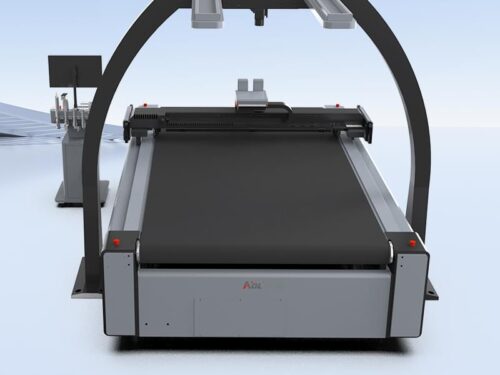

6. Material handling systems: PU leather cutting machines often have specialized material handling systems to ensure smooth and precise movement of materials during the cutting process. These systems may include vacuum tables, clamping mechanisms, or roller feeding systems, depending on the machine design and application requirements.

Parameters of PU leather cutting machine:

| Technical parameters / model | AOL1625 | AOL1825 | AOL2125 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

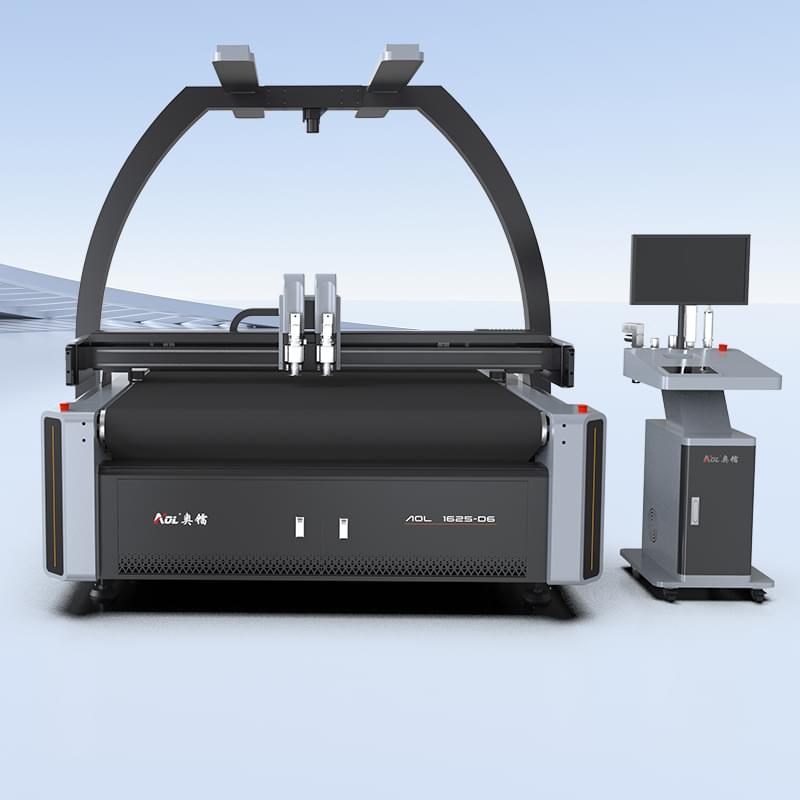

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | foam, vinyl, cardboard, paper, lable, fabric, gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Advantages of PU leather cutting machine:

1. Independent cutting, precise and smooth cutting quality.

2. The automatic nesting effect saves time, effort and material, which can be clearly seen on the leather through the projection system.

3. Various materials widely used in the footwear industry: knitted materials, cloth, PU, PVC mesh.

4. Equipped with a vacuum zone adsorption system, continuous cutting can be achieved.

5. Meet production goals such as multi-layer cutting, various orders, patterns, and customized materials.

6. The gantry form is adopted, the machine is stable and shock-absorbing, and the accuracy and durability are further guaranteed.

7. Operation method: HD projector positioning system + material-saving intelligent nesting software, high-precision cutting.

PU leather cutting machine is a valuable tool for industries that use PU leather material. These machines offer precise cutting capabilities, high cutting speeds and versatility, providing significant advantages in efficiency, productivity, material savings and design flexibility. By investing in a PU leather cutting machine suited to their specific needs, manufacturers can streamline their production processes, improve product quality, and remain competitive in the market.

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.