Nylon is widely used in various clothing products, such as sportswear, casual wear, pants, skirts, shirts, jackets, etc., due to its durability, wear resistance and good elasticity. However, traditional cutting methods often have limitations and cannot meet the increasingly diverse needs. The emergence of nylon fabric CNC cutting machines has provided convenience in cutting for the nylon industry!

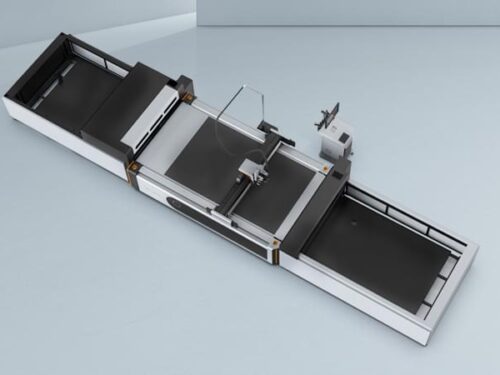

CNC cutting equipment uses digital programs to drive the movement of machine tools. As the machine tools move, the cutting tools that come with them cut the objects. This kind of mechatronic cutting equipment is called CNC cutting equipment!

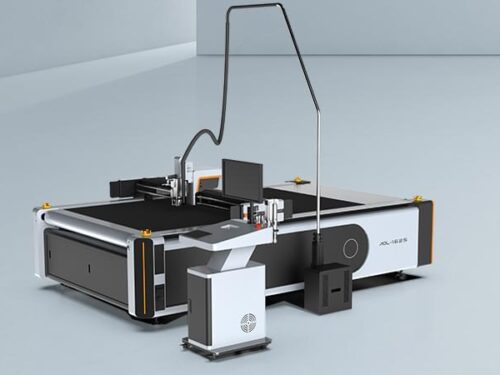

Parameters of nylon cloth CNC cutting machine:

| Technical parameters / model | AOL1625 | AOL1825 | AOL2125 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | foam, vinyl, cardboard, paper, lable, fabric, gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

What problems are encountered when cutting nylon synthetic polymers?

Nylon synthetic polymers are prone to some problems during the cutting process. These problems may have a negative impact on the performance of the material and the quality of the final product. Here are some common problems and their causes:

First, nylon materials are prone to burrs and cracks when cutting. This is because the molecular structure of nylon materials is prone to uneven deformation when subjected to external forces.

Second, nylon has a large thermal expansion coefficient. The heat generated during the cutting process may deform the material and affect the cutting accuracy. In addition, nylon is also prone to static electricity during the cutting process, which absorbs dust and debris, affecting the cleanliness of the cut surface and subsequent processing. In order to overcome these problems, it is usually important to choose the right cutting machine, tool, and adjust the cutting speed and parameters.

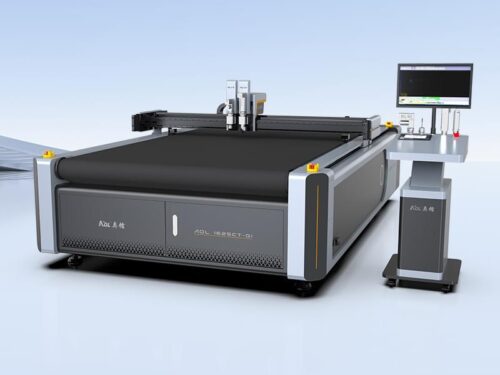

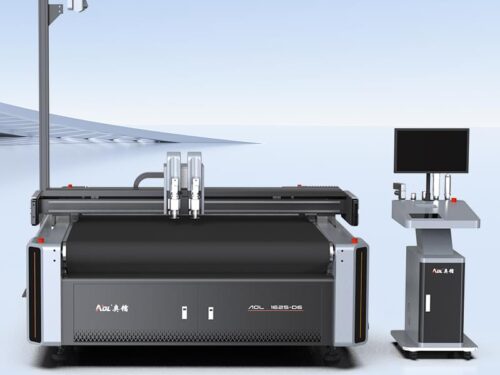

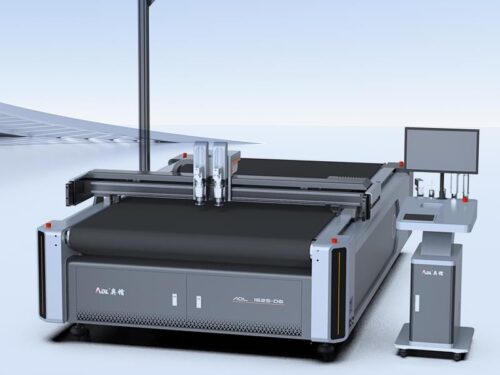

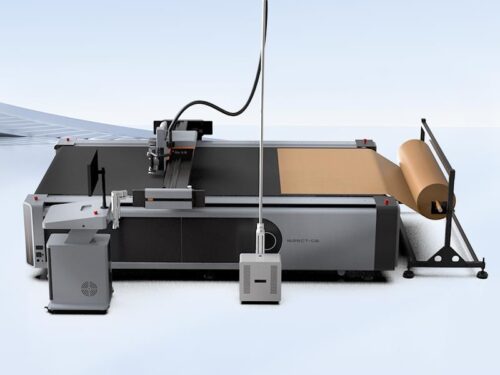

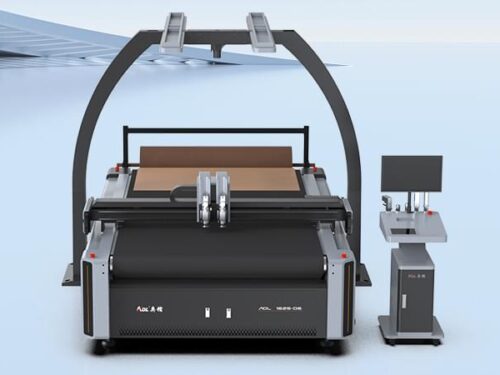

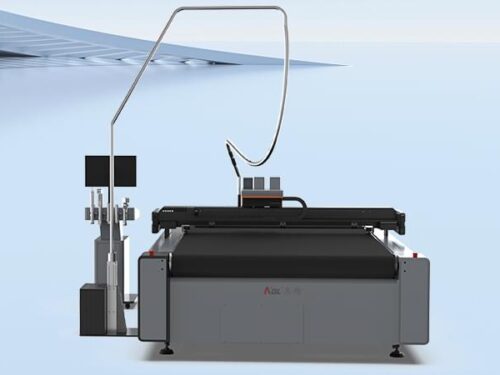

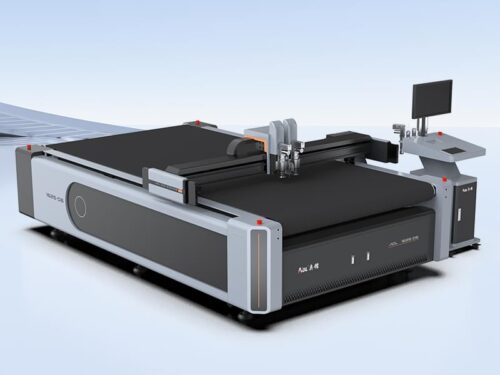

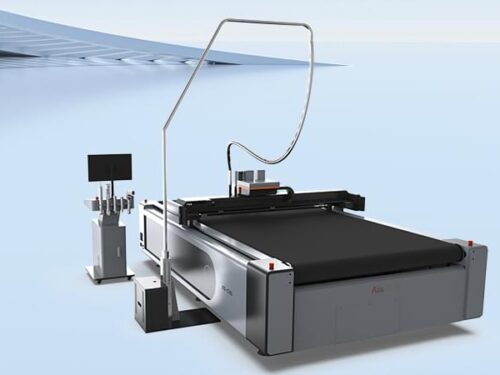

In terms of machine selection, you can consider AOL’s 1625 model, 1825 model and customized model, which are equipped with diversified tools with three types of cutter heads. In order to meet different industrial cutting needs, the cutting head can flexibly choose standard head, punching head and milling head. While meeting high-precision requirements, the cutting speed can reach 4-6 times that of traditional manual methods, greatly shortening working hours and improving production efficiency.

It can be customized in different sizes, has a flexible working area, and can be equipped with a system that accurately controls the depth of the cutting tool through an automatic cutter system. It is equipped with a high-precision CCD camera, and the system can automatically position various materials. The camera automatically registers the cutting, solving problems such as inaccurate manual positioning and printing distortion, thereby completing processing tasks easily and accurately.

Check out our equipment in action in the video below!

CNC Oscillating Knife Cutting Machines are a popular type of CNC knife cutting machine that works by vibrating a tangentially mounted knife to cut through the material. This type of machine is suitable for cutting softer materials such as foams, gaskets, textiles, and rubber. The oscillating knife can adjust its cutting speed and depth, making it ideal for creating complex shapes and precise cuts. Additionally, this type of machine can be integrated with a variety of software programs, allowing for a seamless transition from design to production.

Industrial automatic canvas cutting machines offer many advantages, including greater accuracy, faster production times, less operator fatigue, and the ability to process a wide range of materials. They can also reduce material waste because they can cut very close to the edge of the material, minimizing scrap material. The software program used to control the machine can also adapt to design changes more quickly and easily.

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.