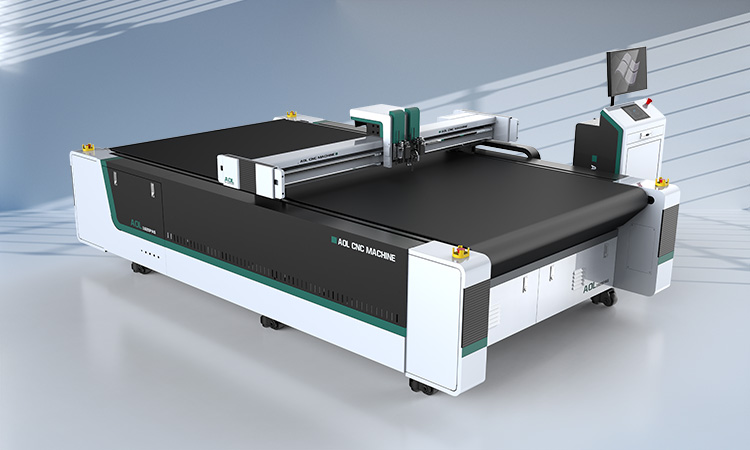

The AOL soundproofing and thermal insulation cutting machine is suitable for cutting fiberglass and exterior wall insulation for HVAC duct systems. With our simple, smooth operating system, complex graphics and products can be cut and produced easily, accurately and quickly. No manual work is required and the parts obtained are ready to be glued. Standard machines come with a host of accessories and equipment designed to reduce production time and produce the best quality finished product.

1. Using advanced cutting system, there is no need to make separate molds, and the processing speed is faster.

2. Intelligent adsorption technology can automatically allocate the adsorption range according to the cutting position. Even if a low-power vacuum pump is used, insufficient adsorption force will not occur when cutting small products, which can effectively ensure cutting quality and save electricity bills.

3. High wear-resistant, high-precision linear guide rails ensure high-speed, stable and high-precision operation of the equipment.

4. Able to cut and process a variety of insulation and related materials in the HVAC field, including fiberglass, aluminum foil insulation, rigid insulation, foam insulation, wall insulation, etc.

Features of soundproofing and thermal insulation material cutting machine:

1. Precise cutting:

Using high-frequency vibrating blades, it can accurately cut various types of sound insulation and heat insulation materials. Whether it is foam plastic, rubber material or fiberglass, etc., the vibrating knife cutting machine can accurately cut according to preset parameters and drawings to ensure the accuracy of the required size.

2. Reduce waste:

The cutting surface is smooth and neat, reducing material loss and waste generation. This not only saves raw materials, but also reduces environmental pollution and is in line with the concept of sustainable development.

3. Processing of complex shapes:

It is designed into various complex shapes according to specific usage scenarios to ensure that it can completely cover the required area and effectively block sound and heat. The vibrating knife cutting machine has good flexibility and controllability, and can process various complex shapes of sound insulation and heat insulation materials according to needs to meet the needs of use in different scenarios.

4. Efficient production:

With efficient processing speed and stable performance, it can achieve large-scale production and ensure the consistency and stability of product quality, thereby reducing production costs and improving production efficiency.

The above is an introduction to the sound insulation and heat insulation material cutting machine. If you want to know more comprehensive content, please click here to contact us! We will give you detailed answers as soon as possible!