Digital cutting machines in the textile and apparel industry are a technology widely used in the design and production process. These machines perform cutting tasks through digital control systems, increasing production efficiency, precision and flexibility. Below is an in-depth discussion on digital cutting machines for the textile/apparel industry:

Cutter modular combination:

High-speed rotary knives, grooving knives, drilling knives and other cutting tools can meet the needs of various garment fabric cutting applications;

Advanced software:

Can meet your personalized production needs;

Inkjet Tools/Drawing Pens:

For use in cutting operations that require marking of cut parts;

Accept various customization requirements

application:

The required equipment size can be customized according to the size of the material being cut.

Parameters of digital cutting machines in the textile/apparel industry:

|

Technical parameters / model |

AOL-1625 |

AOL-1825 |

| Effective working area | 1600x2500mm | 1800x2500mm |

| Multi-function tool | Pneumatic knife, projector,vibrating knife,Round knife | |

| safety devices | Using infrared sensors, responsive, safe and reliable,Anti-collision system,Four corner emergency stop button | |

| Cutting speed | 300-2000mm/s | |

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |

| Applicable materials | Long-haired carpets, carpets, car floor mats, textile carpets, cotton and linen carpets, Particle fleece,Diatom mud carpet, fake wool carpet, printed carpet,etc. | |

| Material fixing method | Vacuum partition adsorption | |

| Transmission port | Network port | |

| Transmission system | The XY axis is divided into two kinds of rack or belt | |

| rated power | 11kw | |

| Rated voltage | 380V±10%/220V±10% Optional | |

| Control System | Chinese and English LCD touch screen | |

| Operating environment | Panasonic servo motor, high precision helical gear reducer, Taiwan Yintai rail, Germany Henryan rack, Omron sensor, Schneider low-voltage appliances, Taiwan Mingwei power supply, Germany cable, 42mm adsorption platform, automatic feeding, Taiwan rail, energy saving fan | |

| Support file format | AI、PLT、DXF、PDF、 PCE、XML | |

| Overall size | 3600*2400*1250 | 3600*2600*1250 |

Textile/apparel industry digital cutting machine working video:

AOL provides customized digital cutting systems for the apparel and apparel manufacturing sector. They are suitable for cutting a variety of woven and knitted fabrics to make suits, shirts, dresses and more types of garments. Equipped with a high-resolution vision camera system, it can quickly and accurately position and contour cut stripes, plaids and different patterns. Additionally, our digital cutting machines are equipped with a user-friendly operating system, creating a perfect platform for your garment manufacturing.

Characteristics of digital cutting machines for the textile/apparel industry:

Automatic nesting

Achieve fully automatic layout on textiles, while matching stripes and plaids, with the highest material utilization rate. This provides an optimal cutting layout and gets the job to production faster and more accurately.

Vision scanning contour cutting

The vision system recognizes the contour marks printed on various materials and then automatically achieves precise cuts. The entire process eliminates the need for manual cutting where the paper pattern is needed.

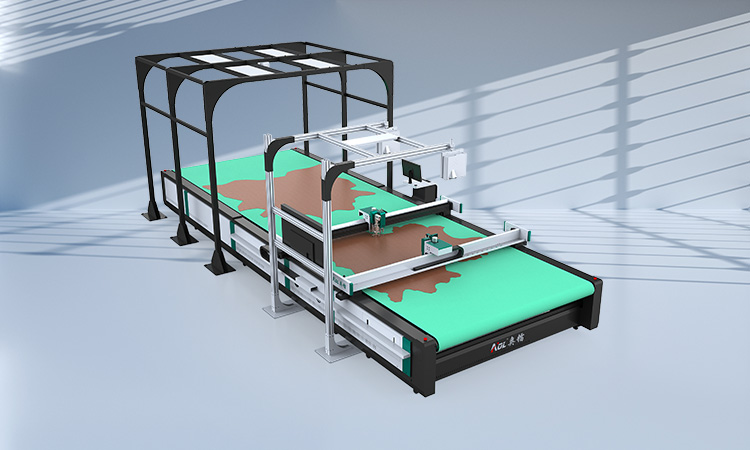

Conveyor table and unloading table (integrated)

It allows the operator to collect cut pieces while the machine works continuously, improving cutting efficiency.

Automatic layout and cutting of horizontal striped T-shirts

The vision system automatically recognizes horizontal stripes and realizes automatic typesetting and cutting. The entire process does not require manual operation.

Innovative tailoring of knitted T-shirts

The operations from fabric feeding, cutting to collecting are completed efficiently, requiring only one person to operate. It is the perfect way to solve the elastic deformation of knitted fabrics.

Simultaneous feeding and cutting

Unmanned operation is achieved through automatic cloth feeding and cutting, ensuring high efficiency in uniform and garment manufacturing.

2.0cm high precision cutting

Meet the needs of multi-layer cutting for small batch production.

Projection system for precise cutting

The projection system for cutting path alignment can effectively replace traditional manual cutting methods that require paper patterns.

Dynamic projection of multiple colors

Objects are projected in various colors, providing efficient classification of cut pieces. It allows operators to better identify the material to be cut and prevent cutting errors.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/