The Flatbed Cutter is a revolutionary model that transforms a simple cutting machine into a versatile production system. This is a great example of how far cutting technology has come over the years.

It was invented to help create and develop custom shapes and designs from prints or materials. Over time, these tools have evolved from hand tools to advanced computer-aided machines that come in many forms, each designed for a specific task.

Working principle of flatbed cutting machine:

Generally speaking, flatbed cutting works on a variety of materials, including fabrics, fibers, foam, foil, paper, plastic, metal, rubber, composites, and laminates. It’s also great for cutting other materials that can’t be cut efficiently on roll stock, such as thick reflective vinyl, magnetic materials, or thin materials like window film.

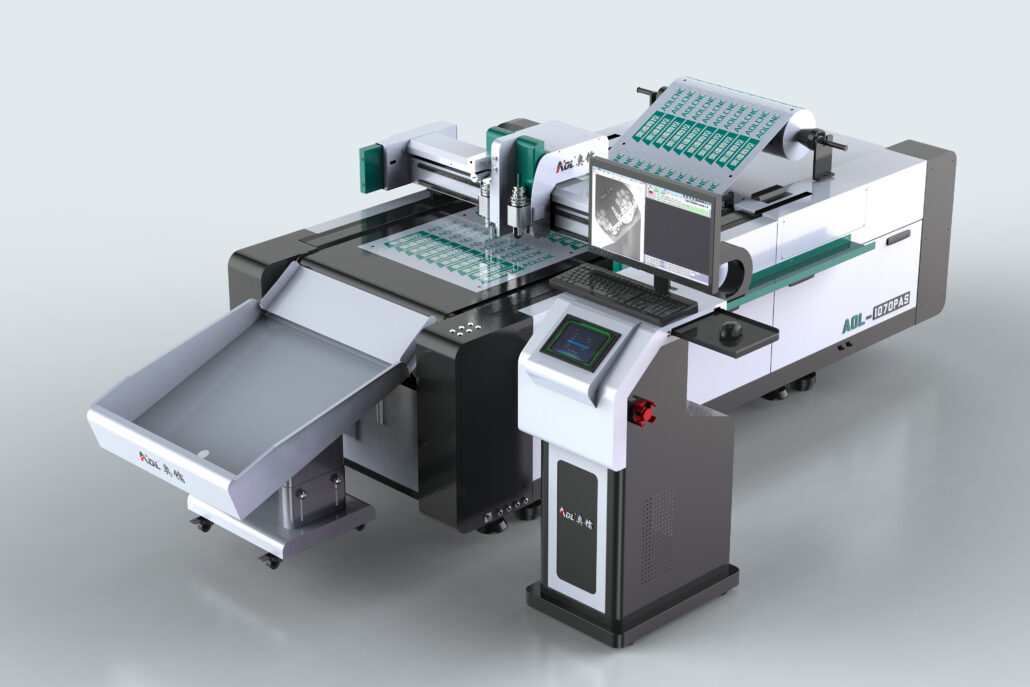

Place the piece of material flat on the cutting table. Meanwhile, the AOL cutting machine’s computer-assisted system is equipped with a camera and a detachable cutting module that moves the cutter head along the x- and/or y-axis to easily cut materials in user-designed patterns. Due to its computer-based dependence, it is also able to copy the design as before if needed. For projects that require the same cut multiple times, a modern flatbed cutter is ideal.

It’s easy to see why flatbed cutters like the AOL have become a must-have tool for professionals and amateurs alike in numerous industries due to the equipment’s adaptability and versatility to materials.

However, AOL has set a new cutting standard for traditional flat panels. It is capable of processing thicker materials (up to 50 mm thick). It can also generate automatically controlled vacuum for any task while reducing energy consumption and operating costs compared to other products. Its advanced systems, including light barriers and 4 emergency stops, take safety to the next level.

Advantages of flatbed high-speed digital cutting machine:

All flatbed cutting plotters are designed to greatly speed up the cutting process for a given project rather than cutting by hand. In fact, they are designed to not only shorten time but also reduce the number of personnel required. Compared to manual cutting, computer-assisted flatbed cutting machines can quickly and accurately cut a variety of materials with extremely high precision, allowing you to create a variety of shapes on a variety of materials. Results can be achieved with simple outlines or more complex concepts.

Creativity is not lost and flexibility is often enhanced. Another benefit of a flatbed cutter is that it reduces the possibility of human error, thereby increasing efficiency and productivity. Therefore, over time, the company or individual will see a reduction in cutting costs, resulting in an effective return on investment.

Is a flatbed cutter right for you?

No matter how you use a flatbed cutter, it’s definitely an improvement over manual work. A flatbed cutter isn’t the only example of a cutting machine, though, and it may or may not be the right tool for you. It all depends on the intended use and what you’re looking for.

Flatbed cutters are often the more affordable option for professionals and hobbyists alike. Given the new level of advanced technology behind the AOL CNC flatbed cutting machine, it offers many clear advantages over any other type of cutter.

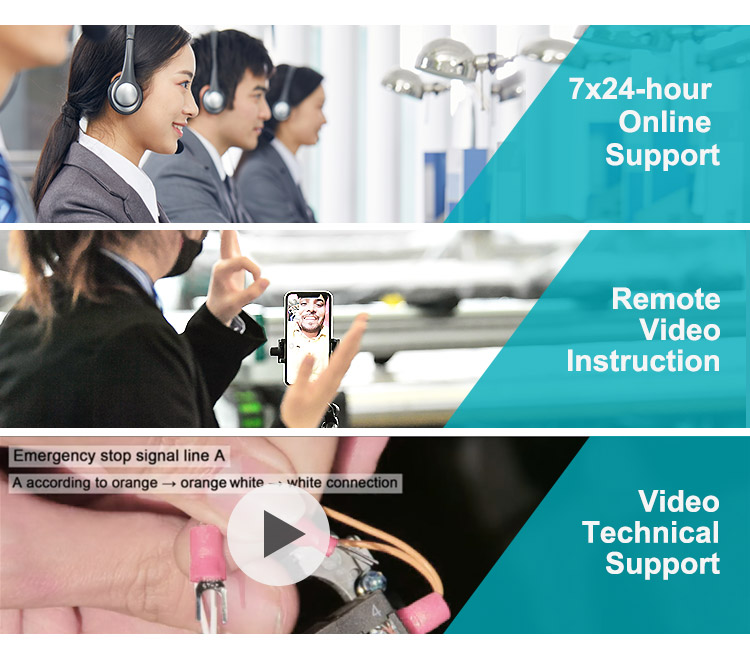

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/