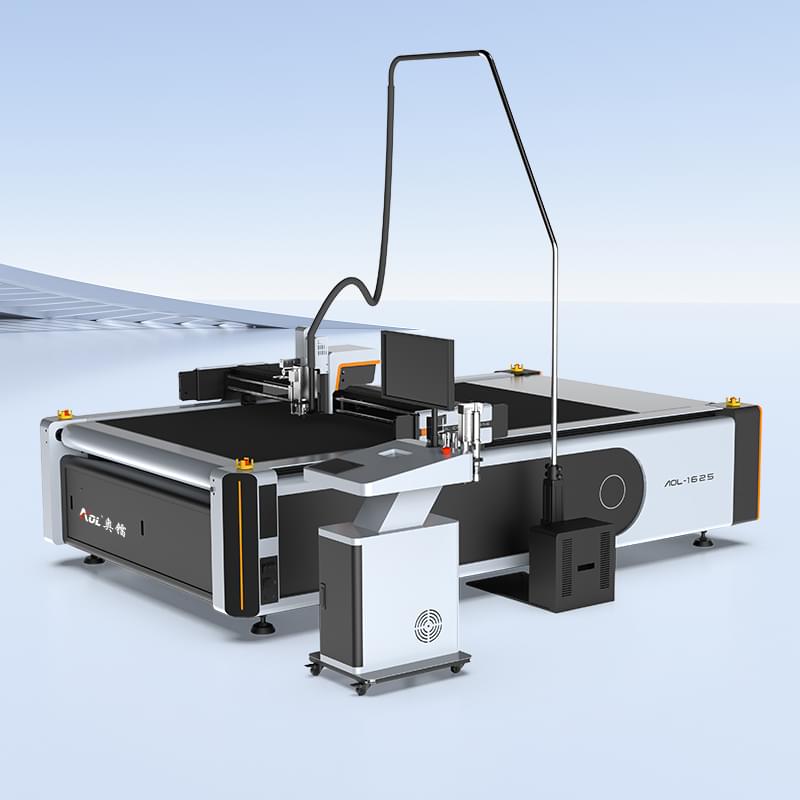

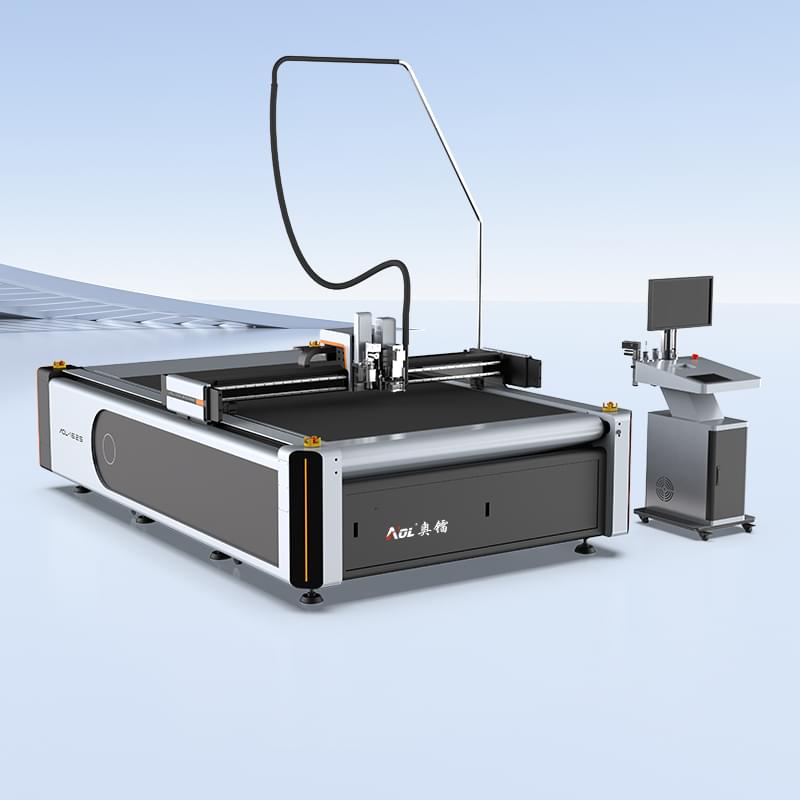

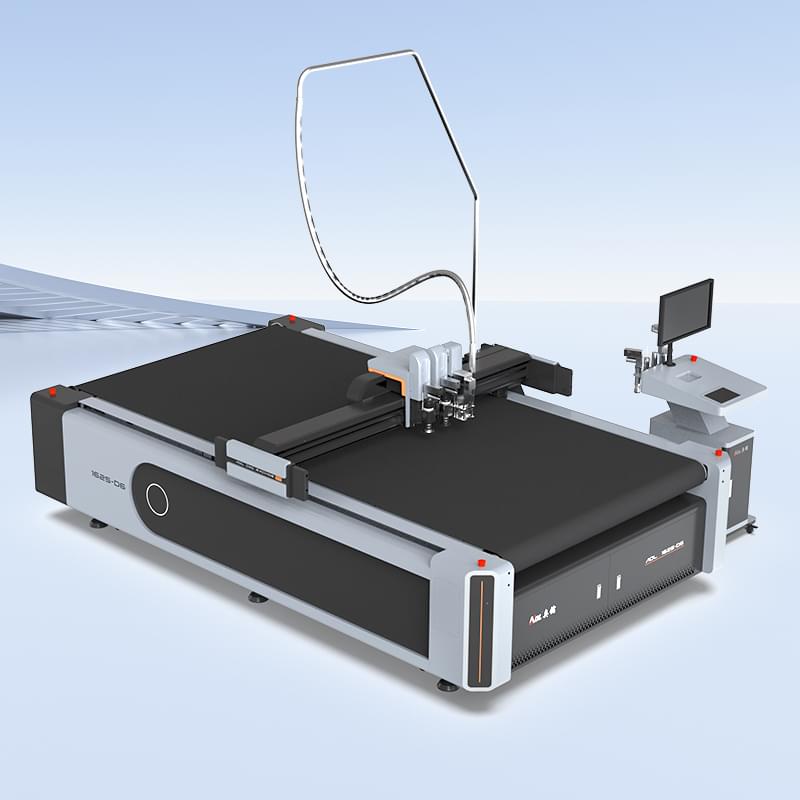

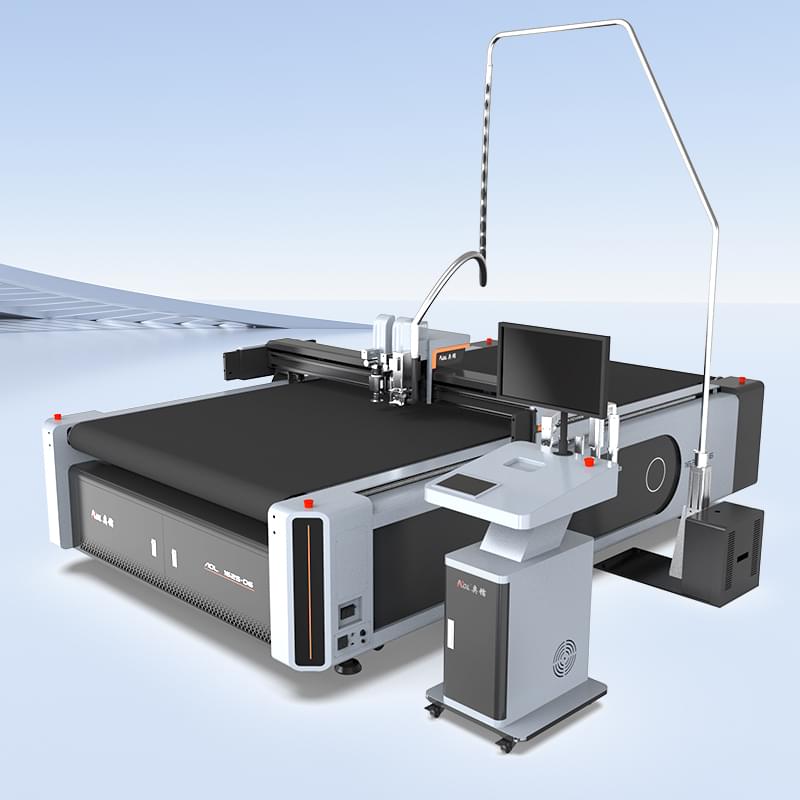

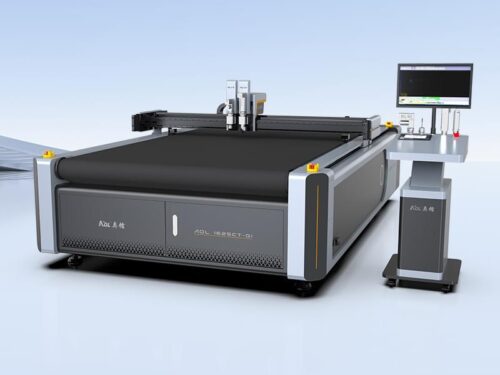

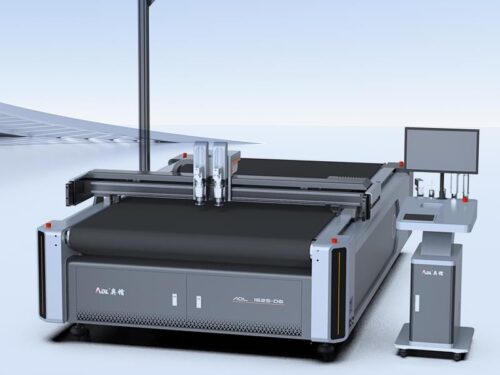

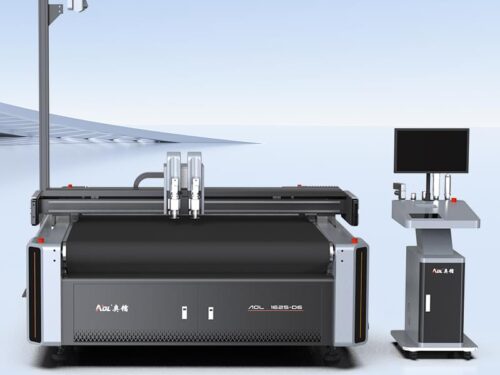

The Industrial Automatic Leather Cutting Machine is an efficient, precision tool that can be used in a variety of industries. An oscillating cutter is a specialized tool that uses a blade that moves back and forth (oscillating) rapidly to cut a variety of materials. These machines are widely used in industries such as textiles, automotive, packaging and construction due to their precision and versatility.

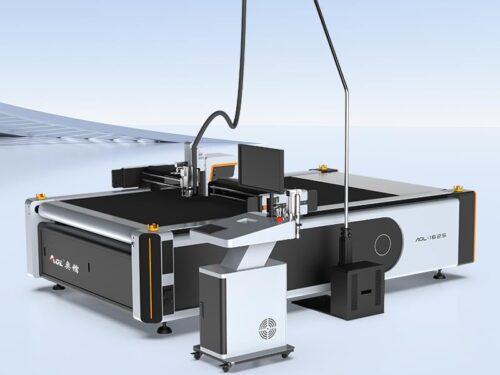

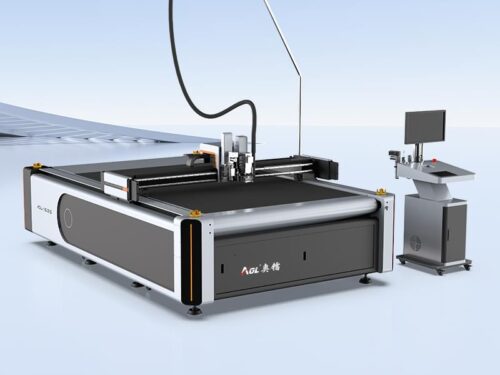

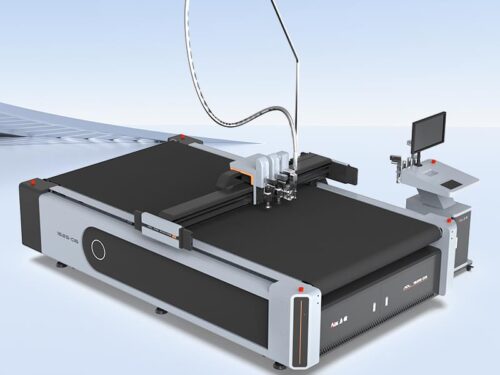

Industrial leather | nylon | canvas | non-woven fabric cutting machine

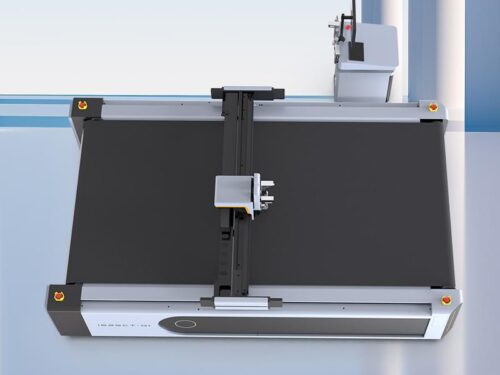

Industrial automatic leather cutting machines equipped with oscillating knives use rapid oscillating motion to cut fabrics precisely and quickly. The oscillating knife moves back and forth at a high frequency, enabling it to cut multiple layers of fabric simultaneously. This oscillating action, combined with adjustable cutting pressure, allows for smooth and accurate cutting without damaging the fabric.

The industrial automatic leather cutting machine uses a vibrating knife instead of a laser. So it will not burn the material and has no odor.

CNC leather nylon canvas nonwoven cutting machines are suitable for small businesses that want to increase production efficiency, reduce labor costs and improve product quality. However, small businesses should consider their budget and production volume when investing in a CNC knife cutting machine. It is important to choose a machine that suits the specific needs of the business and has a reasonable return on investment. Finally, adequate operator training is essential to fully utilize the technology and maximize benefits.

Parameters of industrial leather | nylon | canvas | non-woven fabric cutting machine:

| Technical parameters / model | AOL1625 | AOL1825 | AOL2125 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

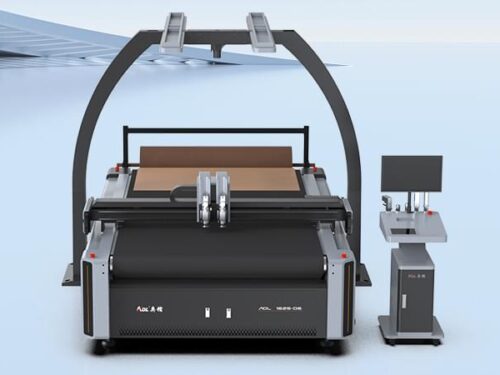

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

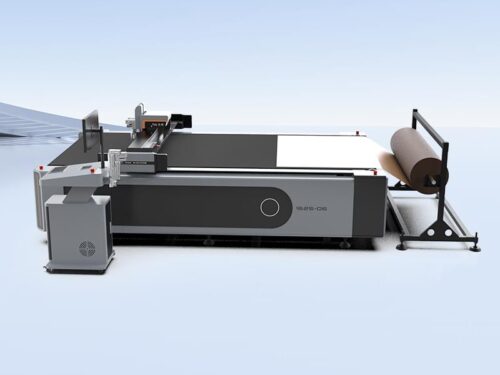

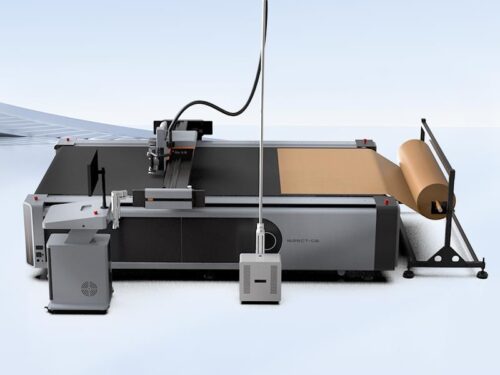

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

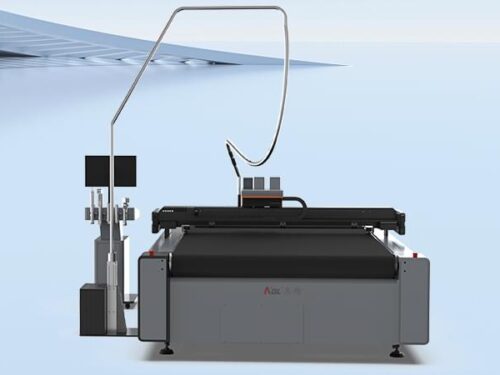

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | foam, vinyl, cardboard, paper, lable, fabric, gasket,cotton, linen, silk, blends, fibers, leather, etc. | |||||

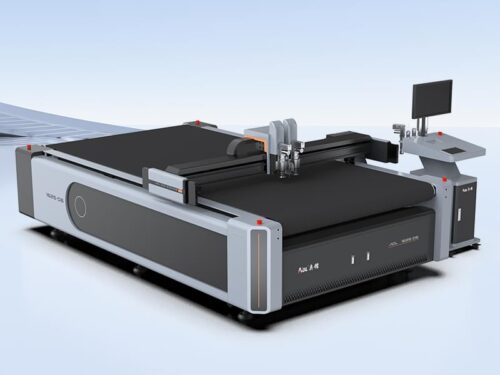

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Advantages of automatic cloth nylon cutting machine:

1. Increased Productivity

Oscillating knife technology enables fabric, nylon, canvas, nonwoven cutting machines to achieve extremely high cutting speeds without compromising quality. This significantly increases productivity and enables mass production of apparel, home textiles, and other fabric products.

2. Precision Multi-Layer Cutting

The oscillating motion of the oscillating knife facilitates precise cutting of multiple layers of fabric in one go. This stacked cutting capability is ideal for industrial applications that require high-volume production of sample pieces.

3. Minimize Fabric Damage

Unlike rotary blades, oscillating knives apply even pressure across the entire cutting edge, reducing friction and heat buildup. This results in a clean cut with less fabric deformation, edge wear, or burn marks.

4. Longer Blade Life

Oscillating blades experience less wear than rotary blades because there is no grinding action during the cutting process. As a result, oscillating blades can last up to 10 times longer, reducing overall replacement costs.

5. Customizable Settings

The oscillation frequency and cutting pressure of the oscillating knife can be customized based on fabric thickness and density. This ensures optimal performance for a wide range of materials.

Benefits of using CNC fabric, nylon, canvas, non-woven fabric cutting machine:

Accuracy: Minimizes material waste and ensures high precision in cutting.

Efficiency: Increases production speed and reduces downtime.

Cost-effective: Reduces labor costs and reduces fabric waste.

Consistency: Produces uniform cuts and maintains consistent quality.

Flexibility: Adapts to various production needs and can handle different types of fabrics.

Here are a few things to consider when choosing a fabric cutting machine with an oscillating knife:

Maximum Cutting Width: The width should fit your standard fabric/textile size.

Stack Cutting Capacity: Machines with higher capacity can cut more layers per time for mass production.

Control System: Look for sophisticated digital controls and programmable cutting parameters.

Blade Type: Choose replaceable oscillating blades for cost-effectiveness.

Safety Features: Look for light curtains, emergency stops, and guards around the blades.

Maintenance and Support: Consider the ease of regular maintenance and support. Providing solutions for many industrial fabric cutting applications.

What materials can CNC knife cutting machines cut?

CNC tool cutting machines are extremely versatile and can cut a wide variety of hard and soft materials. For example, foam, rubber, leather, fabric, composites, plastic, cork, paper and even wood. These machines can also cut intricate patterns and designs into materials, making them ideal for custom products.

CNC Oscillating Knife Cutting Machines are a popular type of CNC knife cutting machine that works by vibrating a tangentially mounted knife to cut through the material. This type of machine is suitable for cutting softer materials such as foams, gaskets, textiles, and rubber. The oscillating knife can adjust its cutting speed and depth, making it ideal for creating complex shapes and precise cuts. Additionally, this type of machine can be integrated with a variety of software programs, allowing for a seamless transition from design to production.

Industrial automatic canvas cutting machines offer many advantages, including greater accuracy, faster production times, less operator fatigue, and the ability to process a wide range of materials. They can also reduce material waste because they can cut very close to the edge of the material, minimizing scrap material. The software program used to control the machine can also adapt to design changes more quickly and easily.

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.