The popularity of CNC cutting machines has now become a trend. CNC cutting machines have replaced traditional cutting methods such as lasers. They have made a great contribution to environmental protection, and the working environment has no peculiar smell and provides safe environmental protection. It is definitely a choice when buying A reliable quality CNC cutting machine, but not only the quality is considered, but the applicability is more important. AOL will introduce you how to choose a CNC cutting machine correctly.

1) Clarify cutting requirements

First of all, we must consider clearly our business scope, the thickness of the cutting material, which materials need to be cut and other factors, and determine the future development plan, whether there is any intention to expand the industry. Then determine the power size of the equipment to be purchased and the size of the worktable. At present, there are cutting blades suitable for different flexible material industries on the market. The worktable surface can generally be customized according to customer requirements.

2) The initial selection of the manufacturer

- After clarifying the cutting requirements, we can go to the market to find out or consult the users who have already purchased the CNC cutting machine to take a look at the performance and basic parameters of the machine.

- Choose a few powerful manufacturers for preliminary communication and quotation and contact to communicate cutting samples,

- After screening powerful merchants, if conditions permit, you can go to the factory to inspect and discuss the price of the machine, the training of the machine, the payment method, after-sales service, etc. in more detail.

3) Selection of machine cutting performance

- While selecting the performance of the machine, first determine whether the material to be cut requires high cutting accuracy. Most of the cutting methods of laser cutting machines are rough machining, which is suitable for cutting materials with low accuracy requirements. The CNC cutting machine can achieve relatively accurate cutting for identification and selection.

- When selecting the performance of the CNC cutting machine, we should fully consider our own environment. The cutting thickness of the cutting machine is very important. We need to choose the blade depth and motor power according to the thickness and hardness of the material to be cut. There is no need to choose the pole. Value performance and appropriate specifications can bring the best cutting efficiency, which is of great help to the cost control of the enterprise.

- The CNC cutting machine is controlled by the computer to cut. The most important factor is the operation of the system. The simplicity of the system operation panel determines the difficulty of the operation. A simple operation panel will bring a lot to recruitment. Advantage.

- Cutting speed is also a factor of choice. In fact, the cutting speed is mostly determined by the hardness and thickness of the cutting material, but within the allowable range, choosing a cutting speed is relatively satisfactory. From a long-term perspective , There is a lot of room for improvement in efficiency.

Note: Don’t blindly choose a merchant because of the price. You must fully understand the product performance and distinguish the quality of the machine, and choose the machine from a comprehensive perspective.

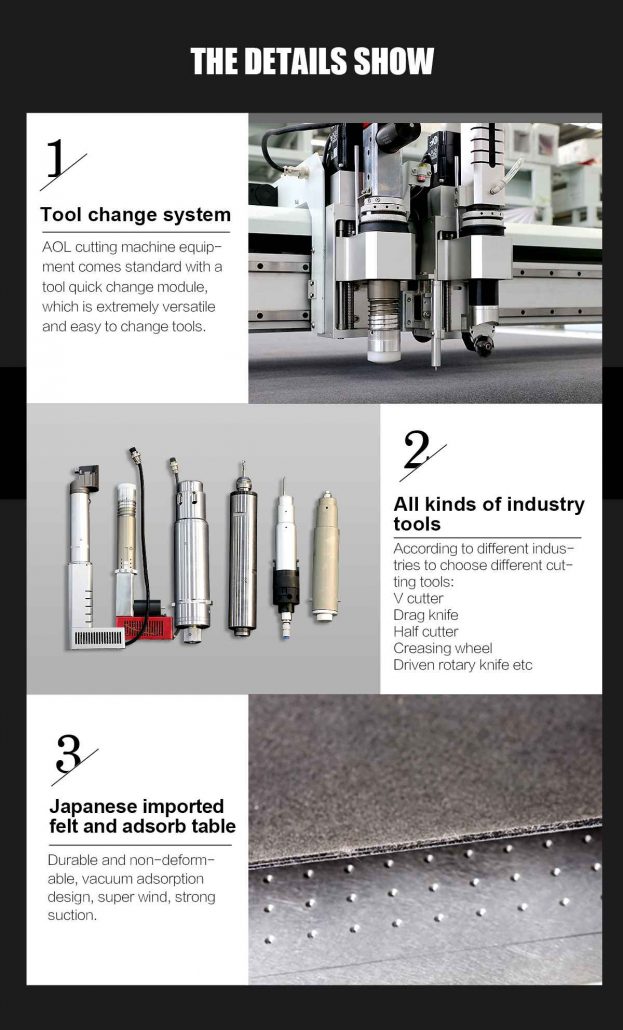

4) Selection of important accessories

We also need to pay great attention to some important parts of the CNC cutting machine. Especially for blades, cutter heads, servo motors, guide rails, etc., attention should be paid to the screening quality. These components directly affect the cutting speed and accuracy of the CNC cutting machine.

The cutting of the CNC cutting machine is not limited to through cutting. The CNC cutting machine supports different cutting methods, such as kiss cutting, V-groove, kiss cutting, milling, marking, etc. These tools can be freely performed according to their cutting needs Match.

The selection of auxiliary functions is also more important. For example, some materials need to be projected and positioned or industrial cameras are used for contour extraction. The selection should also be made according to the actual situation. This can save 10% of the machine cost and improve work efficiency.

5)After-sales service

No matter how well a CNC cutting machine is made, users will encounter operational technical problems in the process of using it, so whether it has a professional after-sales team is particularly important, as well as the response speed of the after-sales and the timely delivery of solutions. It is also an important factor that we need to consider when choosing a CNC cutting machine. This will affect the future development and production. If the after-sales response speed is not timely, it may delay the entire order plan.

If you find this factor difficult to distinguish, it is recommended to look for a merchant that integrates industry and trade. If you have your own production factory, you will have your own after-sales team. Direct feedback will make the solution more efficient. When choosing a trading company, you need to distinguish carefully. It depends on the business experience and the number of customers, as well as the professionalism of the after-sales, so that the after-sales become reliable.

All in all, buying a CNC cutting machine is a decision with a relatively long cycle, because it needs to consider many factors. For the selection of the machine, not all configurations meet the highest standards in the industry. The most important thing is the best fit and the most suitable materials for the industry. The cutting of CNC cutting will bring about rapid economic growth and enhanced competitiveness.

AOL CNC Equipment Co., Ltd. is a high-tech enterprise specializing in the development, manufacturing, sales and after-sales service of flexible material cutting and laser cutting machines. It mainly includes CNC intelligent blade cutting machines, laser marking machines and other types of cutting machines. , It can meet the cutting processing of metal materials and flexible materials of different materials, and is widely used in advertising packaging, composite materials, carpet industry, clothing textiles, automotive interiors, and leather industries. In addition, AOL also has an independent CNC cutting machine brand AOYOO.

AOL CNC Equipment Co., Ltd. is a high-tech industry in China, an AAA-level credit enterprise. The product quality has undergone multiple tests, the after-sales system is complete, and it has a one-to-one professional after-sales team. The fastest response speed to solve user problems has been More than 8,000 users have provided reliable CNC cutting machines, providing high precision and fast cutting.

AOL is committed to multi-industry flexible material cutting solutions for global users. The annual output of high-quality CNC cutting machines in the AOL factory can reach 1,000 units, and each machine is provided with a three-year warranty service.

For more machine performance details, please click

For professional advice, please click to leave a message.

AOL

Material: flexible material

Speed: 1000mm/s

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc. ), it can be widely used in textiles, car interiors, leather, advertising packaging, carpets, composite materials, etc. AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales can provide automatic cutting solutions for various industries.