How to choose the most suitable carton box cutting machine

1. What is packaging (the role of packaging)

Packaging refers to wrapping or bottling products so that they are not damaged during transportation and storage. It keeps the product safe and marketable and helps to identify, describe, and promote the product.

Packaging is a product or commodity prepared for proper storage and/or transportation. It serves the following functions: blocking, supporting, buffering, marking, sealing, binding, weatherproofing, wrapping, etc.

The most commonly used packaging on the market is carton box packaging.The content of this article also introduces carton box cutting machine.

2. What are the types of packaging?

a. Transport packaging

To facilitate counting, storage, and transportation, individual commodities must be collected and packed into large boxes. It is usually required to be durable, not to damage the goods, and to increase the utilization rate. The most commonly used materials for outer packaging are corrugated paper, honeycomb paper, plastic baskets, chemical fiber bags, iron sheets, etc.

b. Sales packaging

Commonly known as small packaging or inner packaging, it is packed close to the product in a certain quantity. Also known as small packaging or inner packaging, directly enter the market to meet consumers. There are many types, including boxes, bottles, bags, barrels, cans, tags, stickers, wrapping paper, waist seals, etc. It can be made of paper, glass, plastic, iron sheet, lead sheet, and other materials. And the same type of packaging also has square, round, multi-angle irregular changes and various forms such as long, flat, high, and short.

Among all packaging, paper packaging is one of the main categories. The output value accounts for about one-third of the overall output value of packaging, and the scope of application involves all aspects of economic life.

Paper packaging is also our focus in this article.This article focuses on the cutting knowledge of paper packaging boxes.

3. What are the commonly used materials for carton box packaging?

Classified by material

a. Cardboard:

Cardboard is also called board paper. There are two types of duty usually used for carton box making, white background and gray background. Also called white paper and gray paper.

Thick paper is made of various pulps and interwoven fibers. The difference between cardboard and paper is usually distinguished by basis weight and thickness. Generally, the basis weight exceeds 225g/㎡ , and the thickness is greater than 0.5mm is called cardboard. (Also: paper with thickness greater than 0.1mm is generally called cardboard. Generally, the basis weight is less than 225g/ ㎡ is considered to be paper, and those with a basis weight of 225g/㎡ or more are considered to be cardboard).

Packaging cardboard, such as box cardboard, kraft cardboard, yellow cardboard, white cardboard, impregnated liner cardboard

b. Paper jam:

The general term for a type of thick paper with a basis weight of more than 150 grams per square meter, which is between paper and cardboard.

There are two types of jams most commonly used for carton making, white paper jam and glass paper jam. The white cardboard paper is firm, white, and smooth. The surface of the glass cardboard is glossy. Cardboard is expensive and generally used for the packaging of high-end products such as gift boxes, cosmetic boxes, hang tags, and wine boxes.

The paper surface is more detailed and smooth, strong, and wear-resistant. According to the application, there are different characteristics, such as postcard cardboard must have good water resistance, beige cardboard must have appropriate flexibility, etc.

c. Coated paper:

divided into single-sided and double-sided. It is mainly made of high-grade raw materials such as wood and flour fiber. It is about 30g to 300g per square meter. Suitable for printing gift boxes and packaging and tagging of export products.

d. Kraft paper:

Low price, economical, but the unique color gives it rich connotation. It is often used as a packaging bag or tote bag.

e. Corrugated paper:

Corrugated paper and honeycomb paper are commonly used. It can be used as transport packaging and inner packaging. According to the size of the corrugated corrugation, it can be divided into thin corrugated and thick corrugated. Generally, the concave-convex depth of 3mm is fine corrugated, which is often used for shockproof paper storage. The thick corrugated paper has a depth of about 5mm. The paper is strong and lightweight. It can load and withstand pressure, and can also imitate vibration and moisture, making it easier to transport.

A general term for a type of paper used for packaging purposes. It can be divided into ordinary packaging paper, special packaging paper, label paper, oil-proof packaging paper, and moisture-proof packaging paper. Usually has high strength and toughness. Various types of packaging paper have different properties and use

Packaging paper includes kraft paper, chicken skin paper, paper bag paper, parchment paper, etc.

Classified by paper packaging materials: packaging paper honeycomb paper, paper bag paper, honeycomb cardboard, kraft industrial cardboard, corrugated cardboard.

There are so many materials for cartons, the following will introduce how to choose the right carton box cutting machine.

4. What are the common cutting methods for wrapping paper?

a. Manual cutting:

Before the carton cutting box machine appeared, the most important cutting method was manual. For small batch orders or DIY enthusiasts, manual cutting is one of the first ways to consider.

Tools: Blade

Disadvantages: cutting accuracy cannot be guaranteed; manual technical operation requirements are high; protection facilities are incomplete, and employee safety cannot be guaranteed.

b. Paper cutting tube machine

Manual alignment-manual feeding-cutting-manual feeding

Disadvantages: manual feeding, high labor cost, waste of time

Simple graphics are easy to operate, but it is difficult to cut special shapes and difficult to meet the needs. Moreover, manual cutting uses a utility knife to draw directly, which is easy to cause burrs on the cutting edge.

Limited to cutting, functions like indentation and marking can only be used with other machines alone, increasing costs.

c. CNC cutting machine (laser for carton box cutting machine)

principle

CNC cutting depends on the digital direction from computer-aided manufacturing (WEB CAM) or computer-aided style (CAD) documents (such as Solidworks 3D). The CNC machine analyzes the design as a guide for cutting model parts. This ability to configure computers to quickly manage equipment tools increases productivity through automation and improves speed and accuracy.

Generally, traditional machining procedures require several types of equipment to manufacture the desired final product (for example, drill bits of different sizes).

Laser cutting equipment usually uses a computerized digital control technology (CNC) device. After using this device, you can use a telephone line to receive cutting data from a computer-aided design (CAD) workstation.

Process: upload CAD drawing → select cutter and blade according to material thickness and hardness → cut

Disadvantages: Laser cutting uses a focused high-power-density laser beam to irradiate the workpiece to quickly melt, vaporize, ablate, or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam to achieve the workpiece is cut open.

Laser cutting is one of the thermal cutting methods. However, the laser cutting machine is not suitable for the cutting of packaging materials, especially the packaging of paper materials such as cartons box.The high temperature of the laser cutting machine can put paper materials in danger, and a lot of waste materials are generated.

d. Digital carton box cutting machine (vibrating knife)

Principle: The CNC cutting system automatically processes the processed parts according to the pre-written processing program (commonly used drawing software AUTO-CAD). We put the processing route, process parameters, tool motion trajectory, displacement, and cutting parameters of the part

And auxiliary functions (tool change, spindle forward, reverse, cutting fluid on, off, etc.), according to the instruction code and program format specified by the CNC cutting system, write a processing program list and then record the content of the program list in the control On the medium (such as perforated paper tape, magnetic tape, disk, magnetic bubble memory), and then input into the numerical control device of the numerical control machine tool, to direct the machine tool to process the parts.

The application range of digital carton box cutting machine is very wide, including metal and non-metal industries. The vibrating knife cutting machine is mainly used for cutting non-metallic materials such as leather materials, cloth, and paper foam.Advantages of digital cutting machine.

Our most recommended carton making machine is the digital cutter.

In recent years, more and more carton manufacturers have chosen to use digital cutting machines to make carton box samples. Many cutting machine manufacturers began to produce digital carton box cutting machine, The price of digital carton catting machine is becoming more and more transparent.

5. Introduce several powerful digital packaging carton box cutting machine suppliers

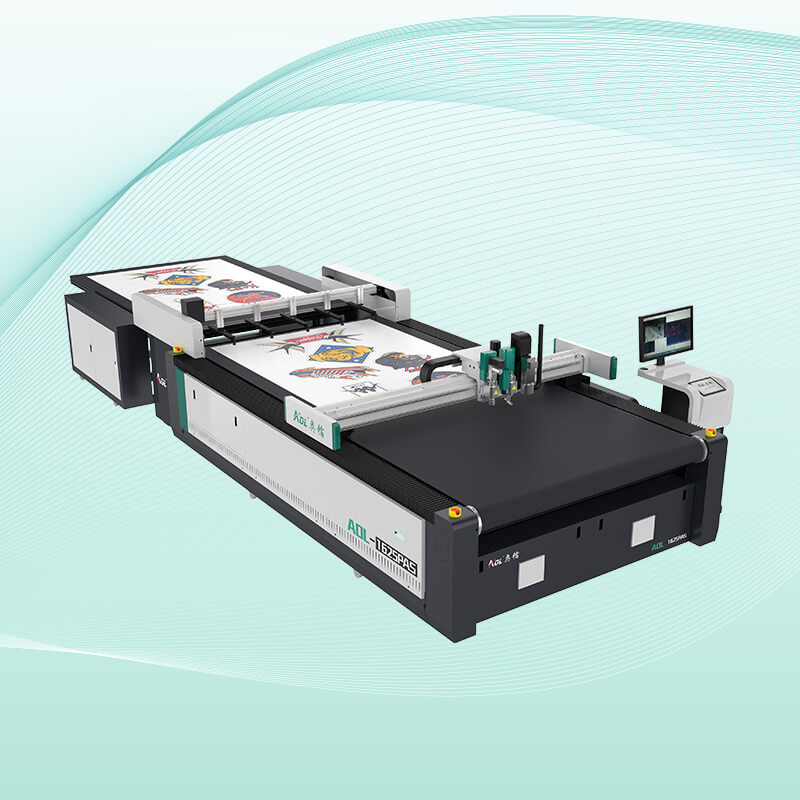

a. AOL CNCfrom China

“Jinan Aol CNC Equipment Co., Ltd. was established in 2010 and is located in Jinan High-tech Industrial Development Zone, covering an area of over 12,000 square meters.

AOL CNC is a high-tech enterprise specializing in the research and development, production, sales, and service of CNC cutting equipment. The company has an experienced team specializing in the research and development of CNC cutting equipment, which can meet the needs of various customers.

AOL has its factory, which can ensure machine quality and delivery time.

There is an after-sales team, the postoperative method is flexible to support online guides, video guides, on-site guides, etc., and can provide services overseas.

The quality of the digital carton box cutting machine produced by AOL has always been very good. With the development of the company, the equipment has been continuously upgraded and the functions have become more and more perfect. Obtained several patented technologies. And the price is moderate, support customization.

The equipment is suitable for cutting a variety of packaging materials, such as corrugated paper, cardboard, stickers, etc.

In recent years, more than 200 packaging industry manufacturers in more than 40 countries have chosen Orion machines.

AOL promises a three-year warranty, and any quality problems in the machine within three years can be solved for free. And provide 7*24 hours online service, any questions after purchase will be answered in time by technicians.

b. Swiss Zünd.

It is the earliest one in the vibrating knife industry. The production of machinery has advanced technology and perfect software functions. Knives can be customized.

Zünd is an independent family business founded in 1984 and has 36 years of experience. Has 215 employees. Currently under the leadership of the second generation. Zünd’s modular cutting system is a highly sought after solution for processing various materials. The versatile Zünd cutting solutions are widely used worldwide.

The product range includes automatic tool changers to collaborative robot technology and fully integrated production lines and comprehensive material handling automation.

The price of carton box cutting machine is currently the most expensive in the vibrating knife industry. If the budget is sufficient, Zünd’s vibrating knife is your first choice.

c. Italian Esko

The Esko product portfolio supports and manages the packaging and printing processes of brand owners, retailers, designers, media and trade stores, packaging manufacturers, and processors.

For 9 out of 10 retail packages, Esko solutions are used for package management, asset management, artwork creation, structural design, prepress, 3D visualization, flexo plate making, workflow automation, quality assurance, sample production, palletizing, Supply chain collaboration, and/or production of signs and displays.

Esko solutions include a wide range of software suites and two hardware product lines: CDI flexo computer-to-plate imager and Kongsberg digital cutting system, supplemented by professional services, training, and consulting services.

Enfocus and its PDF quality control tools and automation solutions, MediaBeacon and its digital asset management (DAM) solutions, as well as BLUE software and its SaaS label and artwork management applications, belong to the Esko series.

d. Hangzhou AGCO.

AGCO is the earliest company in China to make digital carton box cutting machines.

At present, the company has more than 300 employees, and R&D personnel accounts for more than 30%. The company has established a headquarters in Hangzhou, and established two branches in Guangzhou and Zhengzhou, with advanced equipment production lines and technology research and development centers.

Provide professional products and technical services for more than ten industries including clothing, automotive interiors, advertising packaging, composite materials, and luggage. AGCO will adhere to the business philosophy of “high-quality service as the purpose and customer demand as the guide”, dialogue with the future with innovation, redefine the new intelligent cutting technology so that global industry users can enjoy the high-quality products and services from AGCO..

e. U.S. Gerber

The company provides integrated software and hardware solutions for customers in the aerospace, construction, furniture, fashion and apparel, transportation, technical textiles, packaging, wind energy, and sign and graphics industries, including more than 100 Fortune 500 companies in 134 countries the company.

With a rich history of innovation, Gerber Technology’s leading systems help customers achieve their best results by maximizing productivity, reducing errors and waste.

Gerber Technology is headquartered in Connecticut, USA, and is part of American Industrial Partners, a global private equity company headquartered in New York with more than $3 billion in assets under management.

6. The current common machine models of digital carton box cutting machines in the packaging industry

a. Small-6090

Mainly cut paper materials within 2mm thickness, such as cardboard, stickers, etc. Mainly suitable for the production of packaging samples.

b. Large-16250/1825

It can cut materials within 5CM, the cutting speed is fast, the adaptability is strong, and it supports multi-layer cutting. The materials that can be cut include corrugated paper, grey board paper, sponge, foam, and other materials.

7. How to judge the quality of the carton box cutting machine?

a. Test the cutting speed.

Different materials have different hardness, density, and thickness, and the cutting speed will also change accordingly. To determine the speed of cutting machines of different brands and models, the same material needs to be cut.

b. Cutting accuracy.

If it is an industry that requires high material accuracy, such as gaskets, you must pay attention to the accuracy of the cutting machine. The cutting accuracy of different cutters at different speeds is different, so the technician must repeatedly test to find the most accurate cutting method for comparison.

c. Machine stability.

The stability of machine operation is also one of the criteria for judging its quality. Generally, the weight, structure, steel quality, and accessory quality of the bed will affect the stability of the machine. You must check the detailed machine configuration and parameters before purchasing.

d. Whether the operation is simple and easy to learn.

Most brands of only cutting machines will be equipped with operating videos and operating manuals. And in response to customer requirements, arrange for technicians to come to teach. However, there are several brands of machines that are relatively simple to operate and can be learned quickly, and problems encountered in later operations can be quickly resolved.

8.What are the advantages of AOL digital carton box cutting machine?

a. Multifunctionality and modularity

① AOL digital carton box cutting machine provides a customized system to cut packaging materials of different thicknesses and hardness, which can cut cardboard, gray cardboard, corrugated paper, honeycomb carton, and many other packaging materials.

② AOL digital carton box cutting machine equipped with a tool quick-change module, it can work with up to four groups of tools at the same time, greatly improving work efficiency

③AOL digital carton box cutting machine could automatic edge finding: The user can also put irregular materials into the projection area for alignment and cutting, which greatly improves the utilization of materials.

b. Operability

①Match in a semi-automatic mode with millimeter precision in a predetermined rank sequence.

②Within the reserved tolerance range, at the same time, realign the X/Y parts within the locked tolerance range according to the drawing (without bow and deflection).

③The camera bridge with AOL carton box cutting machine, its matching window can perform time overlap work without overlapping tools.

④The software system comes with memory storage, which automatically stores the last cutting file and data storage.

⑤This application of AOL carton box cutting machine does not require professional matching or cutting knowledge. Low standards for professional operation requirements, simple training, can start operating this carton box cutting machine.

C. High-performance customization

①AOL carton box cutting machine adopts imported Panasonic servo motor and imported Japanese belt drive. The machine speed is 2000mm/S. Besides, it has a strong anti-overload capability and can withstand a load of three times the rated torque. The performance of the whole machine is more stable, the service life is longer, the cutting accuracy is higher, and the cutting edges of the carton are more neat and fit.

②Magnesium-aluminum alloy vacuum adsorption table: AOL carton box cutting machine adopts advanced rolling table design, which can realize continuous automatic feeding. The theoretical cutting length is unlimited. The high-strength honeycomb aluminum adsorption table design adopts an eight-zone independent adsorption structure. The flatness of the table is good and will not deform. AOL carton box cutting machine adopts 4mm thick imported felt conveyor belt, which has good air permeability, wear resistance, and long service life. It is equipped with a large suction fan to ensure that the product has a strong adsorption force.

③ According to the needs of customers in different industries, personalized industry material cutting programs.

d. Compared with the laser machine, tthe advantages of digital carton box cutting machine

①Environmental protection: no smoke, no peculiar smell, no harm to human body;

②Non-blurred edge: the cutting edge will not turn yellow;

③Safety. Don’t worry about burning paper at high temperature.

If you want to know more about aol digital carton box cutting machine, please leave a message for consultation.

Durability

The stable structure of the fuselage has a great influence on the cutting accuracy. The fuselage material is welded and sprayed. The body is stable and the material is firm. The machine remains stable during the high-speed cutting process to ensure that the cutting accuracy is not affected.

CNC cutting machines are relatively expensive and have a long service life. The wear resistance of the CNC machine tool rail is several times that of the ordinary CNC cutting machine, which can keep the accuracy of the cutting machine for a relatively long time and can be used for many years. use. extend.

AOL also has cutting machines suitable for other industries and materials, such as corrugated paper cutting machines, textile cutting machines, leather cutting machines, gasket cutting machines, sound insulation board cutting machines… Welcome to learn more

shipping fees

If you buy CNC cutting machines from other countries/regions, you must understand the delivery method and shipping costs. There are multiple delivery methods, such as FOB, CFR, etc. If you have a reliable shipping partner, please save time. If there is no reliable partner, you must find a reliable freight partner before finding the price to ensure that the purchased mac hine can arrive safely.

The above is just a small part of the issues that users consider. In fact, we buy products from the process of knowing nothing. If we know more, we may choose materials that are more suitable for our industry. Click to learn more about AOL CNC cutting machines.

AOL CNC Equipment Co., Ltd. is a high-tech enterprise specializing in the development, manufacturing, sales and after-sales service of flexible material cutting and laser cutting machines. It mainly includes CNC intelligent blade cutting machines, laser marking machines and other types of cutting machines. , It can meet the cutting processing of metal materials and flexible materials of different materials, and is widely used in advertising packaging, composite materials, carpet industry, clothing textiles, automotive interiors, and leather industries. In addition, AOL also has an independent CNC cutting machine brand AOYOO.

AOL CNC Equipment Co., Ltd. is a high-tech industry in China, an AAA-level credit enterprise. The product quality has undergone multiple tests, the after-sales system is complete, and it has a one-to-one professional after-sales team. The fastest response speed to solve user problems has been More than 8,000 users have provided reliable CNC cutting machines, providing high precision and fast cutting.

AOL is committed to multi-industry flexible material cutting solutions for global users. The annual output of high-quality CNC cutting machines in the AOL factory can reach 1,000 units, and each machine is provided with a three-year warranty service.

For more machine performance details, please click

For professional advice, please click to leave a message.

AOL

Material: flexible material

Speed: 1000mm/s

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc. ), it can be widely used in textiles, car interiors, leather, advertising packaging, carpets, composite materials, etc. AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales can provide automatic cutting solutions for various industries.