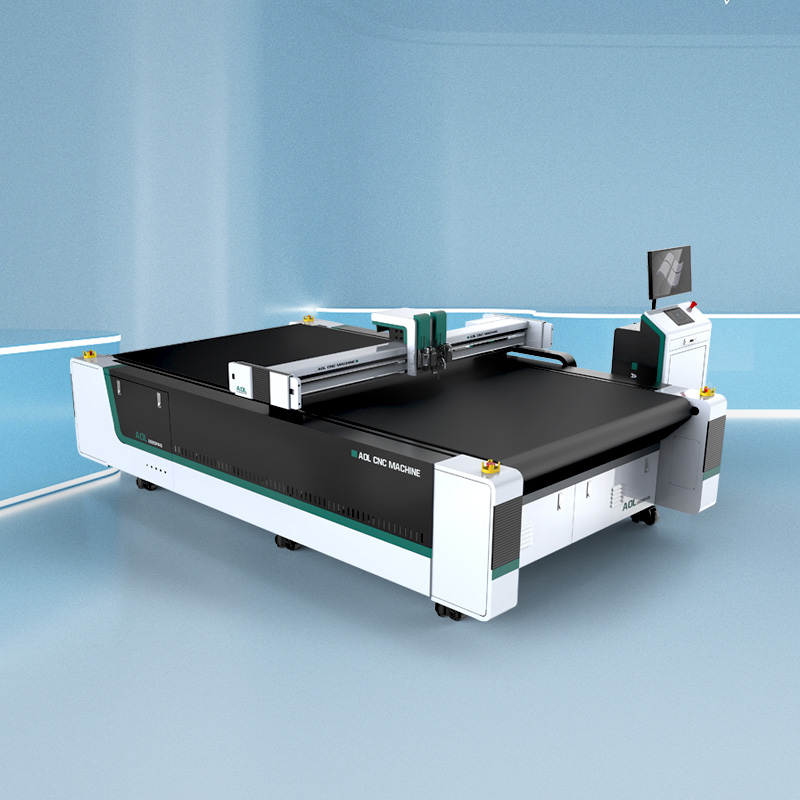

Graphite Polystyrene Sheet Cutting Machine, this advanced cutting machine uses innovative technology to cut precisely and achieve better results than manual methods. In this article, we’ll explore how graphite polystyrene board cutters work, and dig into why these machines are indispensable in various industries.

Working principle of graphite polystyrene sheet cutting machine:

Using computer graphics, the internal data is processed and then transmitted to the machine control card. The control card then sends command pulse signals to the servo drive. The drive drives the servo motor to move to achieve the movement of the machine, and at the same time sends a signal to the cutting tool to cut the raw material. action.

Once the material is in place and the cutting tool is selected, the machine begins the cutting process. Cut speed, depth and other parameters are precisely controlled by the machine’s control system, ensuring consistent and accurate cuts throughout the process.

By automating the cutting process, graphite polystyrene sheet cutting machines significantly increase productivity and efficiency. They can quickly execute complex designs with minimal human intervention, streamlining the manufacturing process and reducing production time.

Graphite polystyrene sheet cutting machines have revolutionized the cutting process across multiple industries, delivering unrivaled precision, efficiency and versatility. With their advanced automation features, these machines simplify production, improve product quality and optimize manufacturing costs. As technology continues to develop, graphite polystyrene sheet cutting machines are likely to become more sophisticated, further driving innovation in industrial manufacturing processes.

If you have any other questions, please contact us, we will reply you as soon as possible!