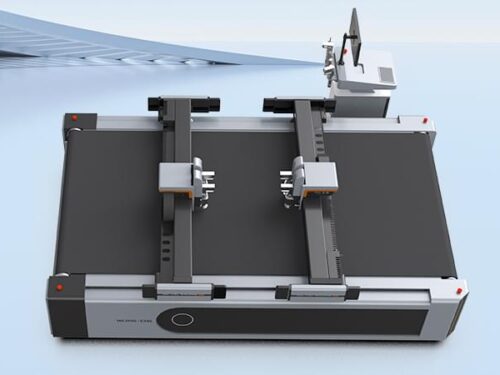

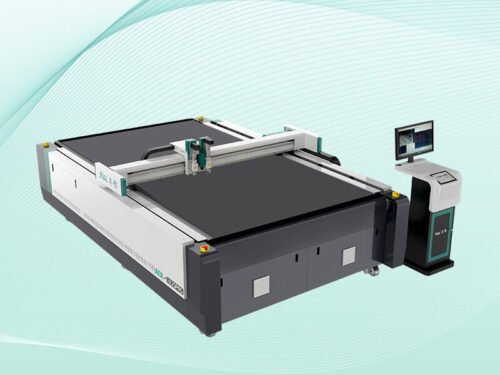

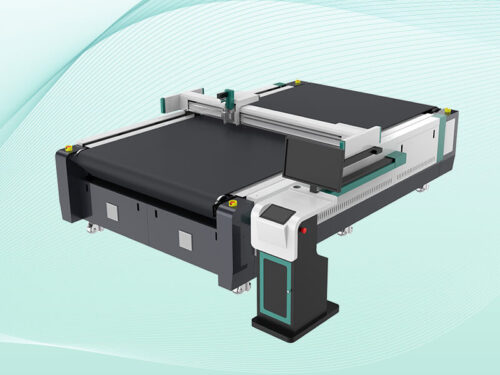

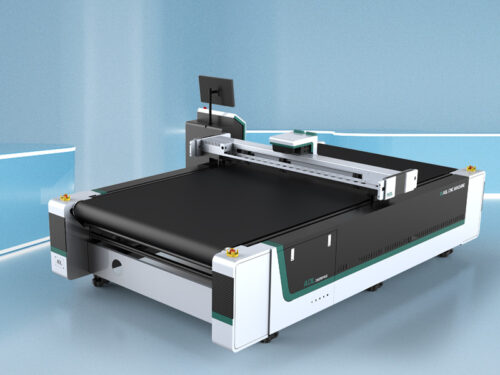

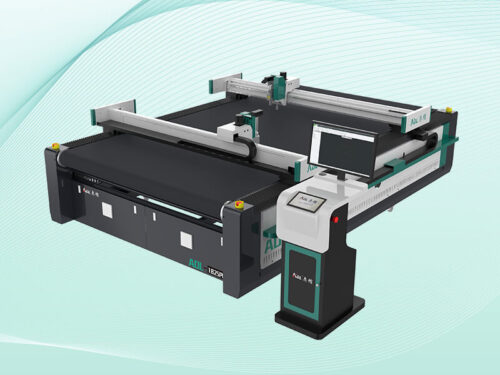

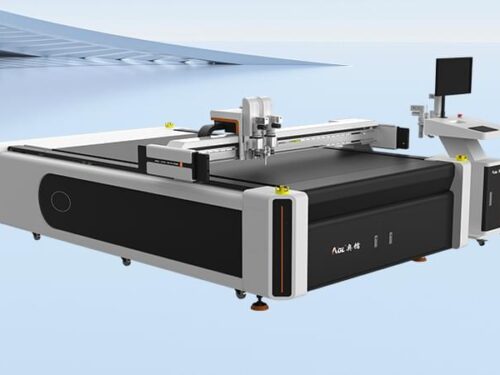

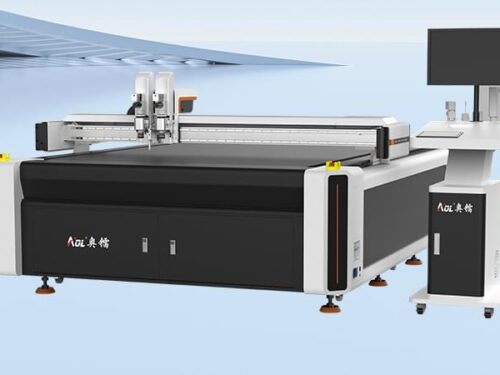

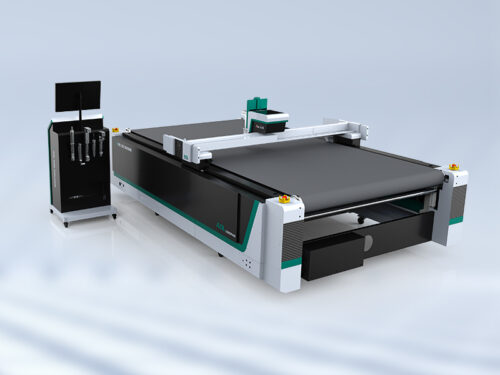

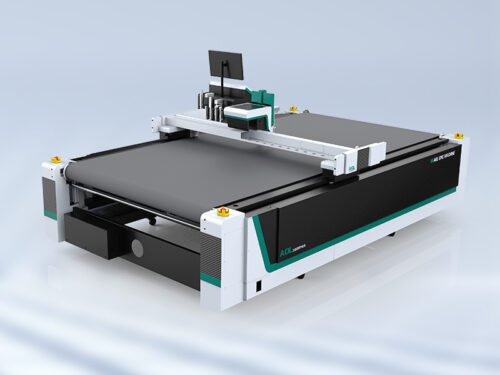

Foam sheet CNC cutting machine is a kind of equipment specially used for cutting lightweight materials such as foam, polystyrene (EPS), polyurethane (PU), EVA, etc. It is widely used in many industries such as construction, packaging, advertising decoration, automobile manufacturing, etc., and it is an ideal choice for processing foam materials with its high precision, high efficiency and flexibility.

Parameters of foam board CNC cutting machine:

| TECHNICAL PARAMETERS / MODEL | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | ACCEPTING SPECIAL-SHAPED CUSTOMIZATION |

|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500mm | |

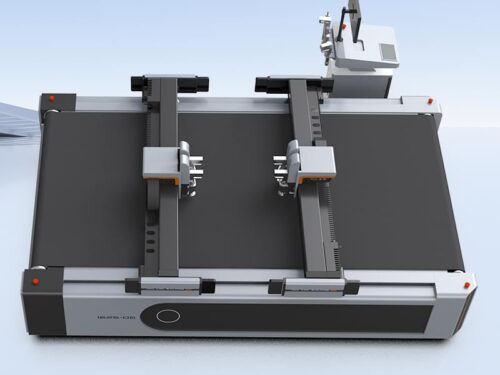

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, semi-cutting cutting, full cutting cutting, camera positioning cutting, edge finding cutting, acrylic milling cutter, cursor positioning, line marking, indentation knife, V-groove knife, etc. | |||

| safety devices | Infrared sensing, safe and reliable | |||

| Cutting speed | 200-2000mm/s | |||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||

| Applicable materials | Various KT boards, Chevron boards, honeycomb boards, car stickers, adhesives, photo frame paper, gray board paper, corrugated paper, EPE foam, PVC board, acrylic sheet, thick foam, etc. | |||

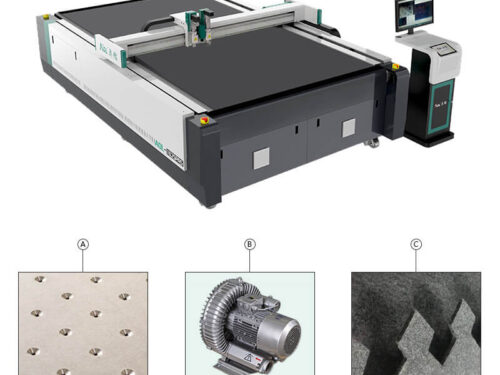

| Material fixing method | Vacuum partition adsorption | |||

| Transmission port | Network port | |||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||

| rated power | 11kw | |||

| Rated voltage | 380V±10%/220V±10%Optional | |||

| Control System | Chinese and English LCD touch screen | |||

| Operating environment | Temperature 0-40°C Humidity 20%-80%RH | |||

| software | Automatic nesting software, camera positioning, large format camera system | |||

| Support file format | AI、PLT、DXF、CDR etc. | |||

The main advantages of foam board CNC cutting machine:

1. High-precision cutting: The foam board cutting machine uses computer programming and excellent control system as an integrated device, making the entire cutting work more stable and accurate, greatly improving the precision of the cutting process.

2. High-efficiency cutting: Compared with the traditional foam cutting method, the emergence and application of the foam board cutting machine has brought about earth-shaking changes in the entire cutting and processing industry. It can recognize electronic drawings from the computer and easily complete the design of any shape, which greatly simplifies the steps of cutting and processing drawing and cutting. It can cut without a mold, effectively plan the cutting path to minimize waste and reduce cutting time, achieve fast and accurate cutting, and greatly improve production efficiency.

3. Automatic control: The foam cutting machine is an intelligent cutting machine. You only need to input the product drawings into the machine, and the machine can realize intelligent automatic cutting.

4. High technicality: Speed, vibration frequency, and cutting depth can be adjusted according to the type of foam. At the same time, the machine also supports a variety of software and file formats.

5. Strong stability: Add a special stabilization device to effectively reduce the vibration amplitude of the equipment and keep the machine performance stable and accurate for a long time.

Common application areas of foam board CNC cutting machines:

Construction industry: cutting and forming of building exterior wall insulation boards, decorative boards, composite wallboards, etc.

Packaging industry: used to produce various types of foam packaging, such as shockproof packaging boxes, electronic product linings, etc.

Advertising industry: making fine advertising decorations such as advertising words and models.

Crafts production: helping cutting, suitable for small batch customization needs.

When purchasing a foam board CNC cutting machine, you can consider the following aspects:

Precision and speed: Choose the appropriate cutting precision and speed according to the application requirements. The advertising and handicraft industries have higher requirements for precision, while the packaging and construction fields are more sensitive to speed.

Machine size: The work surface size of the cutting machine must be adapted to the size of the processed material to ensure the continuity of production.

CNC system: A high-quality CNC system ensures ease of operation and stability. Users can choose a suitable control system according to their operating habits.

Maintenance cost: Understand the maintenance requirements of the equipment and the cost of replacing accessories to facilitate subsequent maintenance and reduce long-term operating costs.

After-sales service: Choose a supplier that provides good after-sales service to ensure support and warranty for the equipment during use.

With the development of automation and intelligent technology, CNC foam sheet cutting machines are also constantly upgrading. The future development trend will focus more on precision processing, intelligent operation and environmental protection. For example, the introduction of artificial intelligence can help the equipment achieve self-optimization and improve the accuracy and speed of cutting; and the promotion of new environmentally friendly materials will further enhance the green performance of the equipment.

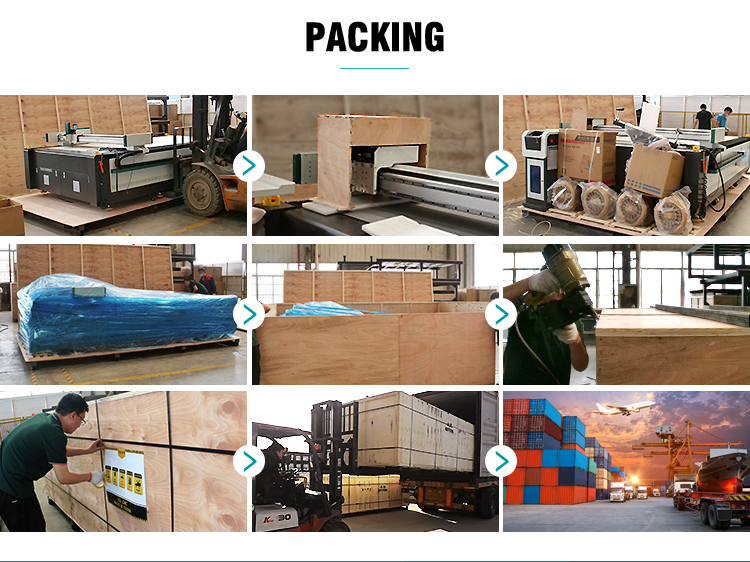

Packing details of CNC foam board cutting machine

Transportation

After sale service

1) CNC foam board cutting machine has three-year free warranty (except vulnerable parts), free inspection and maintenance of main components.

2) Provide lifetime free technology upgrade service

3) Wearable parts (such as blades, workbench covers) are always available at cost when needed.

4) Free operation training is conducted in our factory. If there is not enough time, we will send detailed training videos.

5) 24-hour online service, providing free technical support in different languages.

6) On-site technical support can be provided when needed.

7) After receiving the goods, AOL accepts unreasonable returns within seven days.

Eight reasons to AOL CNC cutting machine

1. Advanced brand: ten years of professional CNC blades

2. R & D advantages: a number of patented technologies, so that the company has a deep deposit

3. Quality assurance: all products have passed European CE certification. US FDA certification

4. High-quality materials: All CNC cutting machine accessories are selected from industry-leading brands.

5. Advanced technology: starting from Germany, foreign advanced technology, technical support

6. High efficiency: implement one-to-one service to improve the efficiency of corporate feedback

7. Personalized customization: With the development and design functions, customers can do whatever they want

8. After-sales service: provide three-year warranty service and 24-hour online solutions.

AOL company info

AOL has obtained CE certificates, FDA and ISO certificates. The company has successfully produced more than 50 AOL series products, enjoying a good reputation and support. Excellent quality and fast service make our products spread all over the world such as Europe, Middle East, America, South Asia and so on.

Welcome to join AOL, we will share top-level machines and services with customers all over the world.

AOL CNC cutting machine is suitable for product customization or sample cutting. It can automatically and accurately perform cutting and other processing. CNC cutting machine supports different types of cutting, (such as through cutting, kiss cutting. V-groove, compliance, milling, etc.

Want to know more machine performance and other information, please leave a message for professional reply.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.