While designing with fiberglass offers unique advantages, cutting and handling this material can present challenges. The strength of fiberglass and the demands of marine and wind manufacturing environments mean that the cutting tools you choose must be both durable and reliable. The right fiberglass cutting tool must be able to cut dry, wet, coated or impregnated woven and multiaxial reinforcements as well as chopped strand mats. Fiberglass comes in a variety of orientations—unidirectional, bidirectional, multiaxial or random—and each construction method can affect the speed, throughput and blade type required of your cutting system.

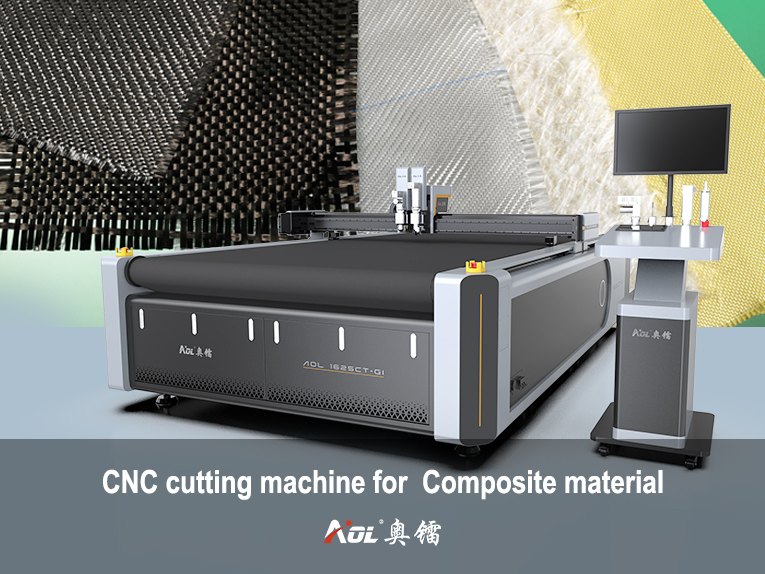

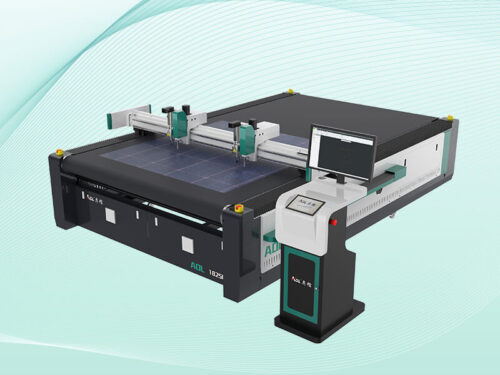

CNC (Computer Numerical Control) Cutting Machines: These machines use computer-controlled precision to cut fiberglass sheets or shapes according to programmed specifications. CNC cutting machines offer high accuracy and repeatability and are suitable for mass production or complex shapes.

Features of Fiberglass Cutting Machine

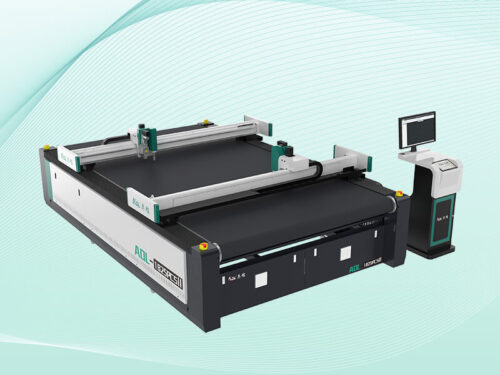

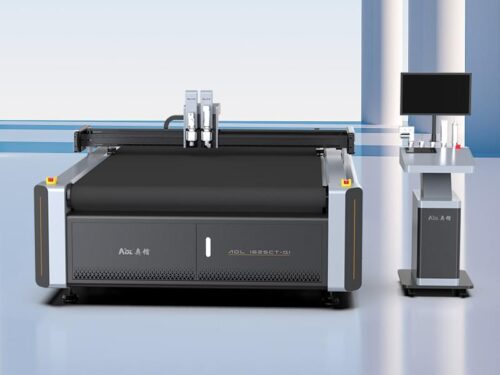

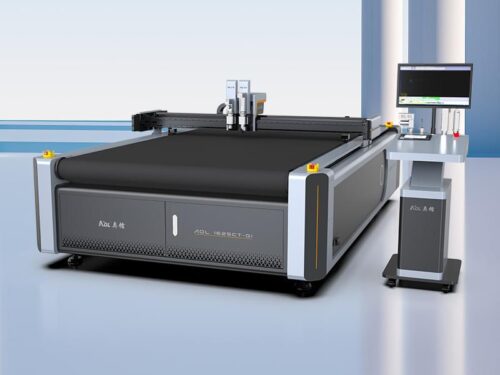

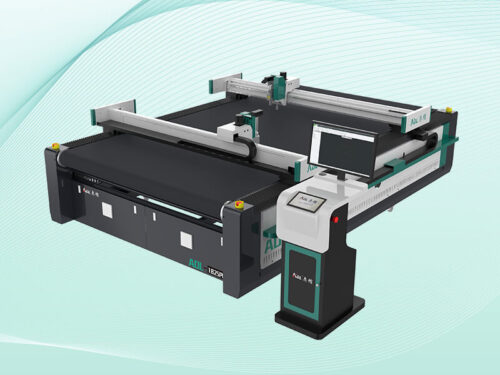

AOL fiberglass Cutting Machine can offer you a modular, flexible, cost-effective expandable cutting system for processing various materials with impeccable precision.

Input the version file into the computer, the fiberglass cutter table can work directly, without open mold.

Operate this fiberglass cutter tool, all the procession just need one person, cut the cost and improve the competitiveness of products.

Use a fiberglass cutting machine to cut plexiglass, fiber, etc. Neat edges, high precision, error within 0.1mm.

High material utilization. And Can cut the non-standard product.

Application of Fiberglass Cutting Machine

The glass fiber cutting machine can not only cut glass fiber, carbon fiber, prepreg, Kevab and other composite materials. It can also cut various flexible materials such as gaskets, leather, cartons, textile cloth, etc.

Advantage of Fiberglass Cutting Machine

1. Multi-functional fiberglass cutting machine that can be quickly changed to adapt to different materials.

2. AOL digital fiberglass cutting machine has an IC control system that offers high-performance and convenient Ethernet with high speed.

3. The Fiber glass Cutter has an English and Chinese LCD touch screen panel and a massive storage volume system.

4. Fiber glass Cutting Machine has the functions of making dotted lines, partial and whole disconnections, perfect backfins, laser positioning and accurate plotting.

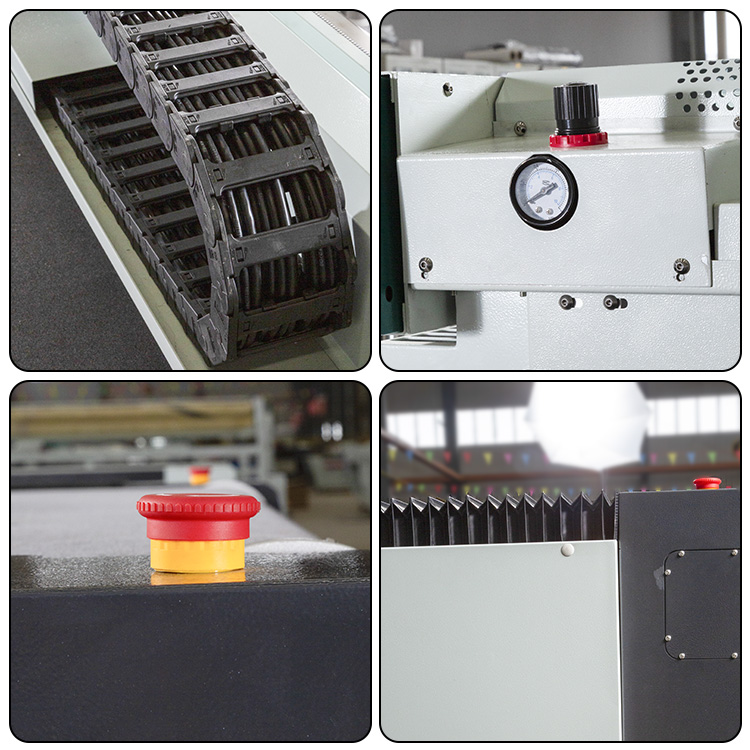

5. The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

Specifications of automatic Fiberglass Cutting Machine

| Technical parameters | AOL-FH1625-PS, AOL-FH1825-PS, |

|---|---|

| Effective working area | 1600*2500MM, 1800*2500MM |

| Multi-function cutting head | The combination of Multi-function cutting head and holders, be with full cut, kisscut, creasing wheel,v-cut and laser red light positioning functions, CCD positioning, Camera extract large contour to cut |

| Tools | Universal Drawing Tool, Creasing Wheel Tool |

| Moving speed | 800-1500mm/s |

| Repeat precIsion | ±0.05mm |

| Interface | Enternet port |

| Control panel | LCD touch screen |

| Drive system | Imported servo motor, linear guid, synchronous belt, screw |

| Cutting material | Glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, boron fiber, aramid fiber, ceramic fiber, soft glass, PVC, leather leather, sponge composite skin, XPE material, wire ring, leather, soft glass , silicone, rubber material etc composite soft material, etc. |

| Instruction system | HP- GL Compatible format |

| Rated power | 2. 2KW |

| Rated voltage | 220V |

| Cutting thickness | ≤50mm(According to different material) |

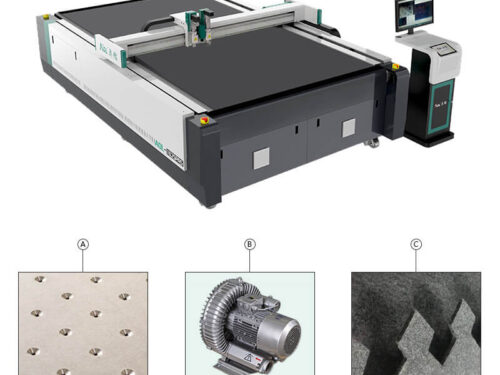

| Material fixed way | Vacuum adsorption |

| Auto feeding system | Acuum sucker adsorpting sheet |

Why cheest aol Digital Glass Fiber Cutting Machine

Customer pain points in the composite materials industry:

1. Manual cannot meet the diversified cutting requirements of special-shaped patterns

2. The price of raw materials is expensive, and the waste rate of manual cutting is high

3. The utilization rate of manual discharge is too low, which increases the cost of the enterprise

4. High-end products have high technical requirements, which cannot be achieved by traditional craftsmanship

5. Special materials have occupational hazards to the human body

Choosing a glass fiber cutting machine can solve the above difficulties

1. AOLCUT self-developed software can be imported with one key, and ordinary workers can work proficiently within 2 hours

2. AOL rapid tool exchange system provides a variety of cutting tool options for various materials

3. Super nesting software, material utilization rate increased by more than 10%

4. Select Japanese Panasonic servo system to increase production efficiency by more than five times

5. Automatic pulling and unloading, saving time, effort and more environmental protection

6. The anti-static system of the whole machine to maximize the protection of personnel safety

There are many machine models produced by AOL, such as carton cutting machine, fabric cutting machine, gasket cutting machine and so on. Welcome to learn more.

Please leave your contact information, and briefly describe the thickness and size of your cutting material, we will recommend a suitable model for you.

MESSAGE

CONTACT

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

No. 1777 Chunhui Road, Licheng District, Jinan City, Shandong Province, China

+86-531-88620680

+86-531-88620680

0086-18560162709

0086-18560162709

+86-531-88620680

+86-531-88620680

Reviews

There are no reviews yet.