A solar panel is a device that directly or indirectly converts solar radiation into electrical energy through the photoelectric effect or photochemical effect by absorbing sunlight. Solar cells are more energy-saving and environmentally friendly green products.

Flexible solar panels are emerging technology products in the world’s solar industry. It consists of resin-encapsulated amorphous silicon as the main photovoltaic element layer. Solar panels made by laying on a base plate made of flexible material.

Manufacturers of solar materials should know that the first step in the manufacture of solar panels is slicing. It uses multi-wire cutting to cut silicon rods into square silicon wafers. So how to cut them, I learned a lot from industry analysis. Local cutting is carried out by manual and laser cutting methods, but there are many disadvantages in these two cutting methods. The emergence of solar panel material cutting machines solves all the disadvantages of the above two cutting methods.

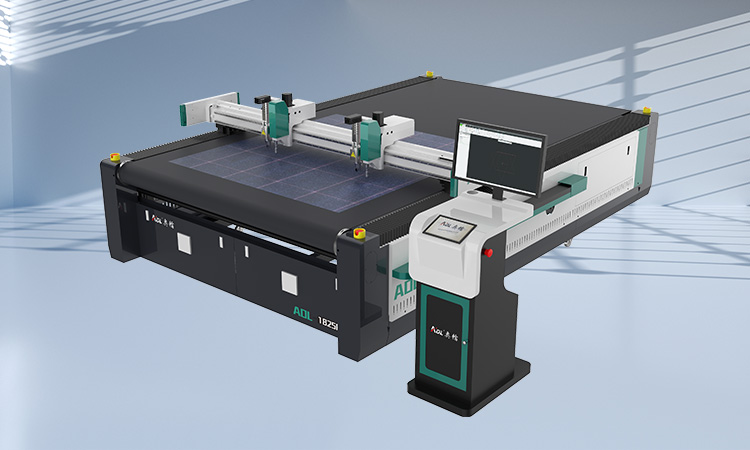

Flexible solar panels have the characteristics of being bendable and foldable and easy to carry. They are usually used in solar cars, solar sailboats (racing boats), and solar heating (or cooling) to pave the way for the popularity of energy-saving homes. The solar panel material contains a variety of circuits, and it is necessary to ensure the cutting effect and the integrity of the material when cutting. AOL solar panel material cutting machine can achieve perfect cutting effect.

Advantages of cutting with solar panel material cutting machine:

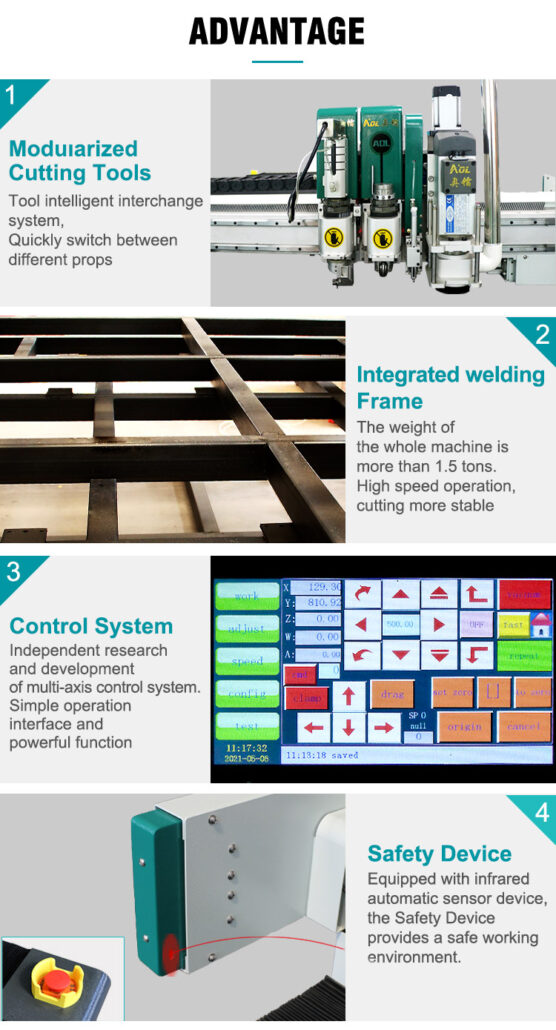

1. The blade cutting method will not cause damage to the material

2. Stable table, can ensure the stability and accuracy during the cutting process

3. Automatic loading and unloading function, saving a lot of labor costs

4. Japan Panasonic servo motor power supply, can ensure stable power supply

The solar panel material cutting machine has a friendly high-definition touch screen man-machine interface, which is simple to operate and easy to learn. Standard network data transmission, fast speed, stable and reliable transmission. It can meet the production goals of small batches and multiple orders, and can be used to cut a variety of flexible materials.

Design and manufacture CNC cutting machines using state-of-the-art technology to provide customers with superior end products. Whether your business is a small store, heavy equipment manufacturer or steel service center, we have the high-performance cutting machines to meet your needs.

About AOL:

AOL is an industry-leading brand with 14 years of industry experience. We have served more than 8,000 customers around the world and received satisfactory reviews. We have many long-term and stable cooperation customers. We provide personalized industrial material cutting solutions for many customers. If you encounter problems in industrial material cutting, we can provide you with free consultation and consulting services!