Oxford cloth, also known as Oxford spinning, is a kind of fabric with various functions and wide range of uses. Oxford cloth is a versatile and versatile fabric, and it is also a commonly used material for luggage customization. Luggage products made of Oxford cloth have always been favored by consumers.

With the increasing use of Oxford cloth materials, how to quickly cut to meet the production speed of finished products is the focus of many businesses. Now this society is becoming more and more automated, many businesses have already started to use automatic Oxford cloth cutting machines to cut materials. Not only can it save a lot of material costs, but also reduce labor costs. Recently, more and more merchants have contacted us and sent us samples for proofing. After seeing the samples, contact our sales staff directly to communicate the order details. What are you waiting for?

What are the main types of Oxford cloth?

Nested Oxford cloth:

It is specially used to make all kinds of bags. The warp and weft of the fabric are all polyester FDY150D/36F. The fabric is made of plain weave and interwoven on a water jet loom. The warp and weft density is 360X210. After the grey fabric is treated with relaxation, alkali content, dyeing, anti-static, coating, etc. and other advantages. Such oxford cloth bags are the best and most common.

Nylon Oxford cloth:

It mainly produces flood and rainproof products. The warp of the fabric is made of 200D nylon air-transformed silk, and the weft thread is made of 160D nylon air-transformed silk as raw materials. It is a plain weave structure, and the product is woven by water jet. After dyeing, finishing and coating, the grey fabric has the advantages of soft hand feeling, strong drapability, novel style and good waterproof performance. Because of its high quality and novel designs, it is deeply loved by users. The width of the fabric is 150cm. It is understood that the fabric is based on the advantages of no fading and no deformation. The listed colors include navy blue, light black, tiger yellow, dark green, etc., and various colors can be selected and dyed in batches according to customer needs.

Full Stretch Oxford Cloth:

It is mainly used for the production of bags. The warp and weft threads of the fabric are made of polyester DTY300D threads, which are interwoven on a water jet loom with a coarse point change air-through weave. After the fabric is relaxed and refined, pre-shaped, alkali-reduced, and soft-shaped, the reverse side of the fabric is then covered with a rubber-plastic polyester layer. The bags made of this fabric are sought after by many trendy ladies who love beauty because of their fashionable appearance, delicate texture and good water resistance, and have become the new favorite in the current women’s bag market. The fabric width is usually 150cm

Teague Oxford Cloth:

It mainly produces all kinds of bags. The warp of the fabric is made of polyester DTY400D network yarn, and the weft yarn is made of polyester DTY 400D. Made with teag weave texture, interwoven on a water jet (with tap) loom. The fabric has novel design and unique craftsmanship. The front plaid is prominent and the three-dimensional sense is strong, making it the most prominent part of the fabric. At the same time, the coating (PU) process is also used on the reverse side to make it more waterproof and drapeable. A fashion item for bags. The width of the fabric is 160cm. The listed colors are mainly black, navy blue, coffee series and so on.

Weft Oxford cloth:

It mainly produces all kinds of bags. The warp of the fabric is made of polyester FDY68D/24F, and the weft is made of FDY150D/36F. The cloth noodles are clear, integrating modernity, artistry and drape. After dyeing, embossing or calendering, the grey fabric has the advantages of strong drape and good water resistance. The width of the fabric is 160cm, and the material is also applied to the production of fashionable and casual gray shoes, because the characteristics of the material itself provide a wealth of choices for wearing and matching!

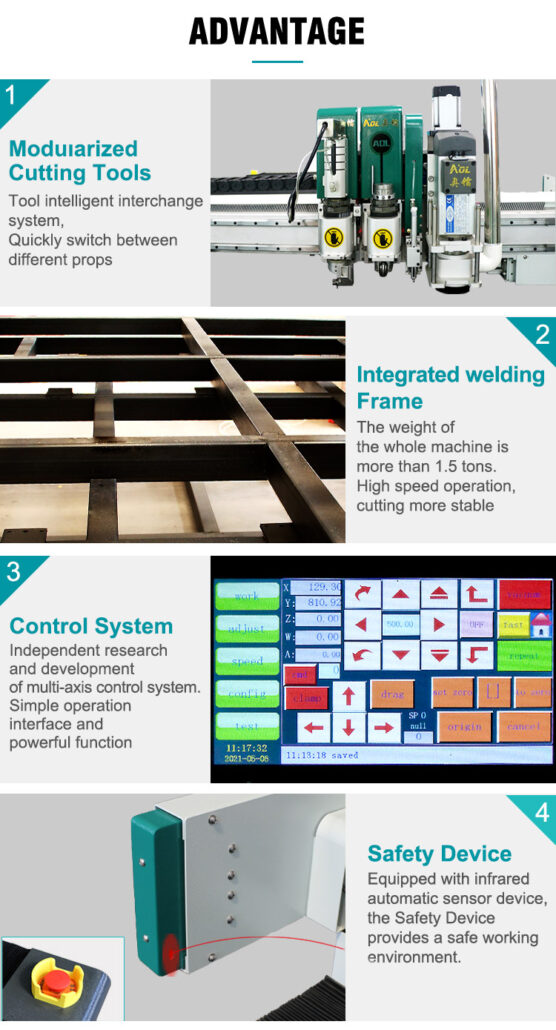

Advantages of Oxford cloth cutting machine:

1. Independently develop and design CAM software, intelligent software compensates, optimizes the cutting path, and improves production energy efficiency.

2. The aluminum-magnesium alloy adsorption platform is durable and does not deform, ensuring that the mechanical cutting is cut through, and the felt loss is greatly reduced.

3. Super nesting software, the material utilization rate is increased by more than 10%.

4. Adopt Taiwan linear guide rail drive system, with an accuracy of ±0.1mm.

5. Anti-static interference and soft start device to protect the safety and stability of the equipment.

6. Infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

7. Suitable for cutting a variety of non-metal flexible materials, including car mats, car interiors, cartons, color boxes, PVC soft glass pads, carpets, leather, asbestos rubber sheets, sponges, composite materials, etc.

8. Supports a variety of file formats, saves manpower and material resources, simplifies the work process, and can be connected to multiple computers at a long distance for man-machine separation operation, which improves the production management of enterprises.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.