The vibrating knife is a new generation of CNC cutting technology in the 1990s, mainly aimed at cutting flexible materials and semi-rigid materials. Using the high-frequency vibration of the blade up and down and the rotation within 360 degrees, the vibration frequency of tens of thousands of times per minute can be used for vertical cutting on the plane, sharp cutting, cutting paper, leather and semi-rigid composite materials. Because the vibrating knife has the characteristics of high cutting precision, no smoke, no smell, no dust, etc., it is an advanced environmental protection cutting technology and has been widely used.

After years of technological development, it is now the most advanced cutting technology in the world. Compared with traditional cutting methods, vibrating knife cutting has the advantages of precision manufacturing, flexible cutting, special-shaped processing, one-time forming, fast speed, and high efficiency. Therefore, in industrial production It solves many difficult problems that cannot be solved by conventional methods. , In 2023, AOL CNC Equipment Co., Ltd. will continue to make breakthroughs in 10 aspects, subverting people’s perception of vibrating knife cutting machines in the past.

1) Digital cutting system. The digital cutting system independently developed by AOL can provide customers with value-added services, create a new ecology of technical services, and open up industrial applications. last mile. The system adopts integrated technology and integrates with computer and multimedia video machine, which has high-speed and high-efficiency processing effect.

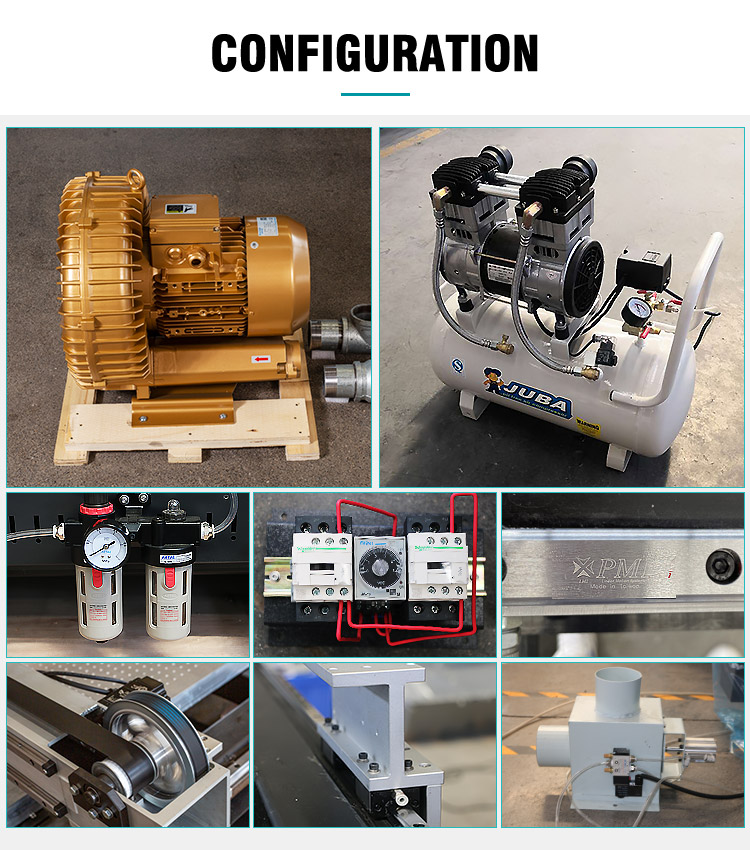

2) Fully automatic loading and unloading system, the automatic feeding system developed by the AOL team, and the coil system are composed of multiple modules such as unwinding, tension control, deviation correction control, automatic feeding, edge patrol positioning, and cycle cutting. We have made in-depth research and development on tension control, deviation correction control, and speed synchronization to maintain the high precision and continuous stability of the cutting machine during production.

3) The working system of the double cantilever system perfectly combines the intelligent double cantilever and the digital vibrating knife cutting machine. It is applied to the field of flexible material processing and has achieved extraordinary achievements. In 2023, the new generation of intelligent cutting robots will have more advanced and powerful functions, Facing the manufacturing industry with increasingly strong demand for digitalization and intelligence.

4) Line-scan positioning and typesetting system; on the basis of laser coordinate positioning and CCD industrial camera positioning, AOL has further developed a line-scan positioning system (software for automatic typesetting and positioning and cutting of digital printing materials), which adopts large-format high-resolution line scan Advanced technologies such as flat-field camera, one-button rapid size image measuring instrument, ultra-wide line array, and wide-format zero-distortion; combined positioning with line-scanning dual cameras, automatic scanning of contours, calculation of deviation correction, and simultaneous transmission of multiple The material level coordinates are given to the cutting machine, and the cutting machine can quickly perform cyclic processing after receiving the instruction. The work efficiency of the post-processing of the line-scan vision solution is 3-5 times that of manual work.

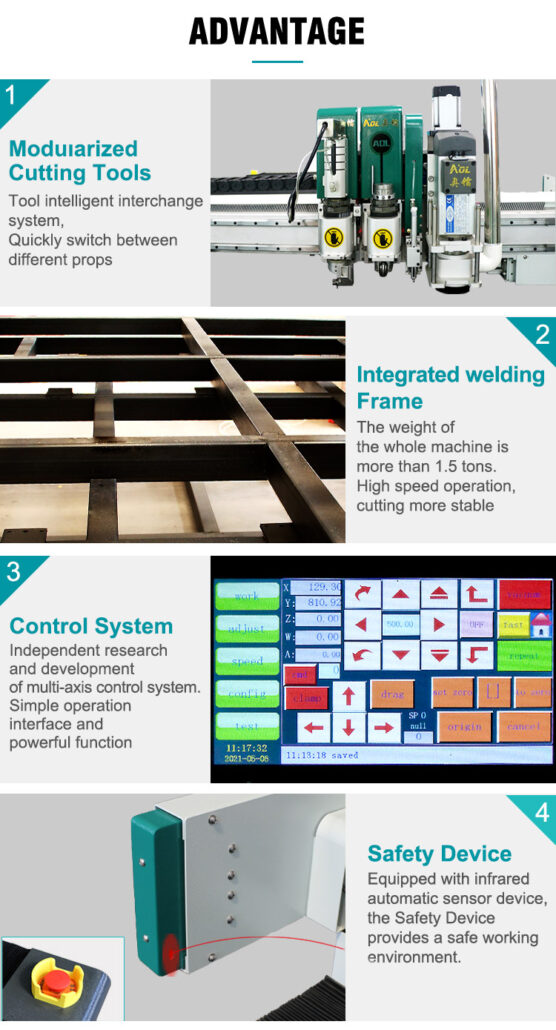

5) Multi-beam and multi-stand cutting machine, which integrates the processing methods of various cutting tools such as vibrating knife, round knife, milling cutter, and pressure wheel, and also integrates automatic feeding, ultra-long format cutting and cutting, and the controller has up to 16 The stepper/servo driver control interface for each axis has 16 limit inputs, 27 special/general inputs, and 43 general outputs. At the same time, it has USB2.0 and 10/100M network communication and U disk file copy function, can work in online and offline mode, and reserves the communication interface for external expansion equipment interconnection.

6) The controller is equipped with an industrial touch screen, the human-machine interface is intuitive and powerful, and it is easy to operate. The controller supports asynchronous machining of double beams (two knives and multiple heads) in two coordinate systems. At the same time, each coordinate system supports the processing method of double heads moving each other. The controller can also support MARK point visual positioning cutting, large-format panoramic visual cutting, and projection cutting and other functions.

7) Reverse positioning system (two-dimensional barcode patrol positioning technology): CCD industrial camera registration system, the registration system is used to capture marks and material edges to achieve fast, accurate and multi-task cutting.

8) Soft and hard through-cut technology; the vibrating knife cutting machine used to be mainly for flexible materials (paper leather cloth and rubber-plastic foam composite materials). Pain points. Many customers need to order the engraving machine again after ordering the vibrating knife cutting machine. Through our continuous R&D and updating, we have designed equipment that can cut through soft and hard. While cutting and processing 0-100mm thick materials, it also provides 0-10mm engraving and processing functions.

9) The cutting thickness above 100mm, the processing thickness of the vibrating knife cutting machine, the technical breakthrough from 10mm to 30mm, the thickness of 30mm to 60mm is the current mainstream cutting height, and now it breaks through the cutting thickness of 0-100mm again, and it is delivered to many users. Be recognized by customers. (Not all materials can be cut to 100mm, please contact us for details)

10) Customized machines are diversified. In order to meet customers’ more diversified needs, AOL provides full customization services, from 600*400mm small-format cutting machines to 2100*2500mm large-format cutting machines, all of which have successfully customized solutions for customers. The vibrating knife cutting machine has developed into a wider field.

If you want to know more, please contact us, whatsapp: +86 18560162709