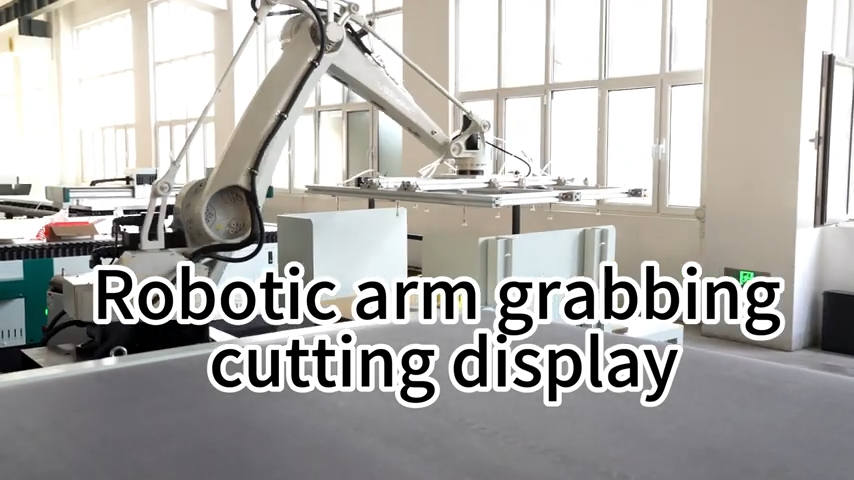

Our modular digital cutting solutions offer the option to add automation. We offer an impressive range of innovations that will improve performance and eliminate the need for manual material handling. With our robotic digital cutting platforms, you have the option to automate the feeding and stacking processes in our wide-format tables. This means you can seamlessly transfer cardboard materials from one pallet to another without any manual intervention.

By implementing this kind of automation, you can significantly increase the efficiency of your cutting operations. It reduces the risk of errors, increases productivity, and minimizes the need for manual labor while maintaining a precise and controlled workflow.

In conclusion, it is important to understand that manual material handling on the cutting table is no longer the only method, as automation offers practical solutions for increasing operational efficiency and precision.

AOL high-speed digital cutting machine is an advanced cutting machine that uses digital technology to cut foam, rubber, plastic, paper, fabric, cardboard, cardboard, carbon fiber fabric and other materials. These materials can all use robotic arms to transfer the material from elsewhere to the cutting platform. These machines are designed to be fast and accurate, with cutting speeds up to 1200 mm/s. They are also very efficient, with cutting accuracy up to 0.01mm.

AOL high-speed digital cutting machines utilize digital control systems to cut materials. The control system uses CAD/CAM software to create the cutting design and then sends it to the cutting machine. This machine uses a high-speed servo motor to move the cutting head and is equipped with high-precision cutters. This cutting tool can cut materials with high precision and speed.

What benefits does the emergence of robotic arms bring to CNC cutting?

1. Increase productivity: The robotic arm operates tirelessly and efficiently, thereby greatly increasing overall productivity. They can work continuously without interruption, reducing downtime and speeding up production cycles.

2. Enhanced safety: By delegating material grabbing tasks to robotic arms, dangerous and repetitive tasks can be taken out of the hands of human operators. This helps create a safer working environment and minimizes the risk of injuries associated with manual operations.

3. Reduced labor costs: While the initial investment in robotic arm technology may be significant, long-term benefits include lower labor costs as less manpower is required for repetitive, labor-intensive tasks.

4.24/7 operation: The robotic arm is not limited by human working hours. They can operate around the clock, helping to sustain production and enabling businesses to meet growing demand efficiently.

5. Optimize material handling: Robotic arms are programmed to handle materials of different shapes, sizes and weights. This flexibility is especially valuable in industries where materials vary widely, allowing for efficient handling of different products.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/