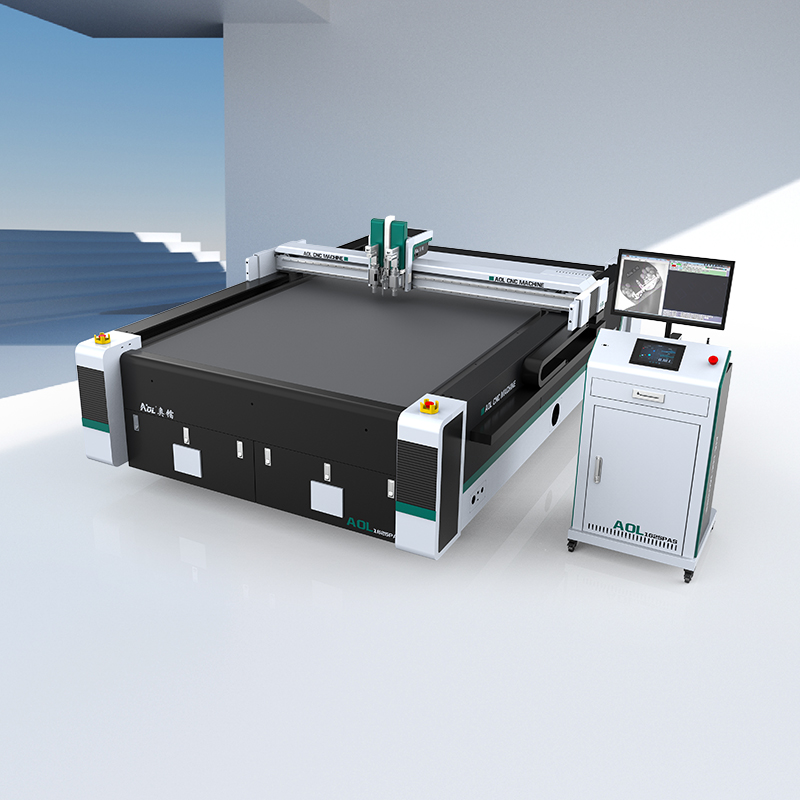

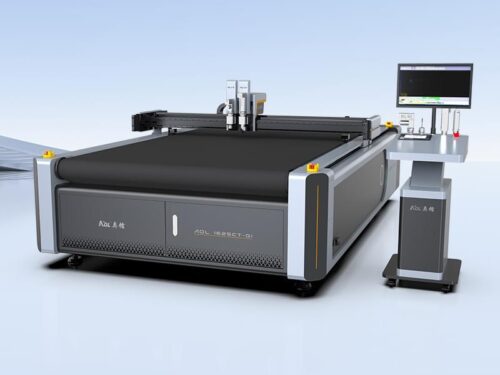

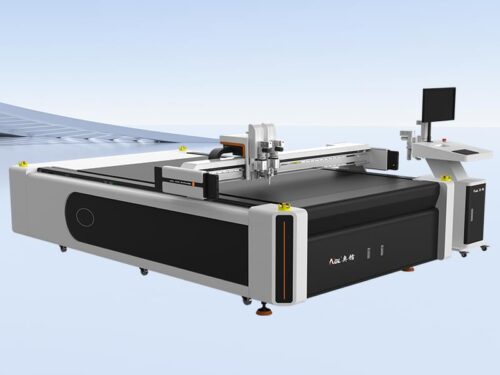

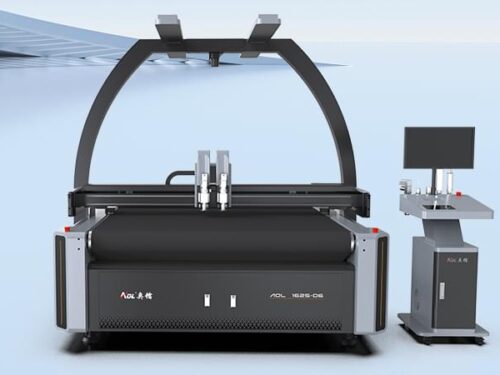

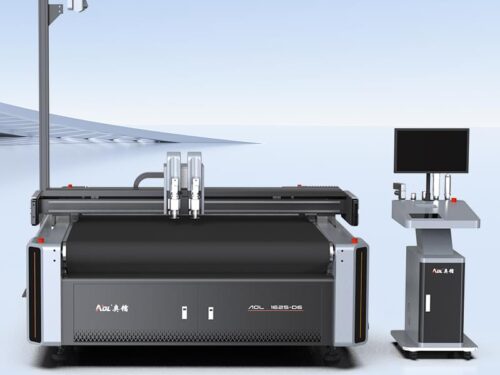

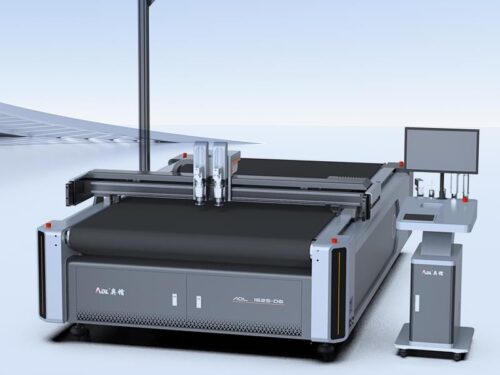

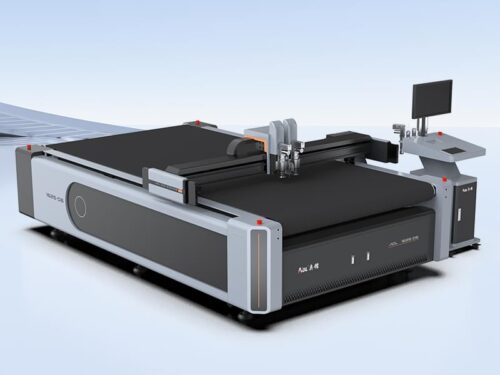

Advantage of CNC Industrial Fabric Cutter Machines

Shop high quality CNC industrial fabric cutter machines from AOL.Buy single or in bulk.Worldwide shipping.Reliable suppliers and certified manufactures.Safe payments and competitive prices.

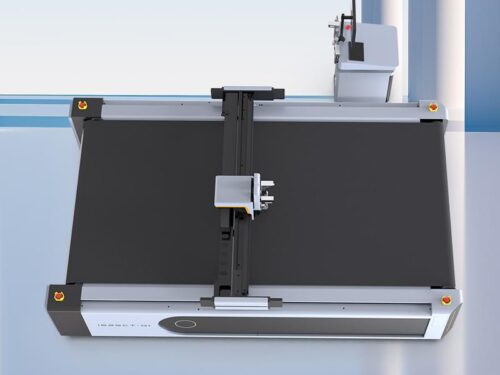

5″ high speed straight knife fabric cutting machine is your best choice for home textile industry.

1. High cutting precision, material saving;

2. Neat and beautiful edge-cutting;

3. Standard Cutting, precision within 0.1mm;

4. Consistent cutting size, without error;

5. CNC Industrial Fabric Cutter Machines can Save more than 20% materials than labor.

Application of CNC Industrial Fabric Cutter Machines

Computer Fabric Cutting Machine can cut can cut fabric, leather, rubber, gasket etc.Also Clothes or decorations made of fur.

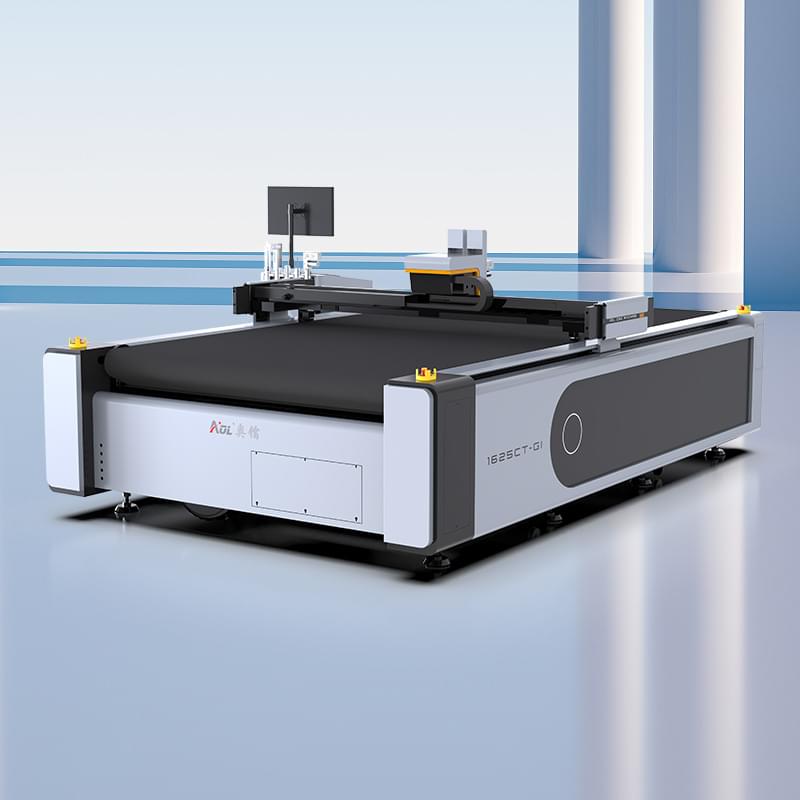

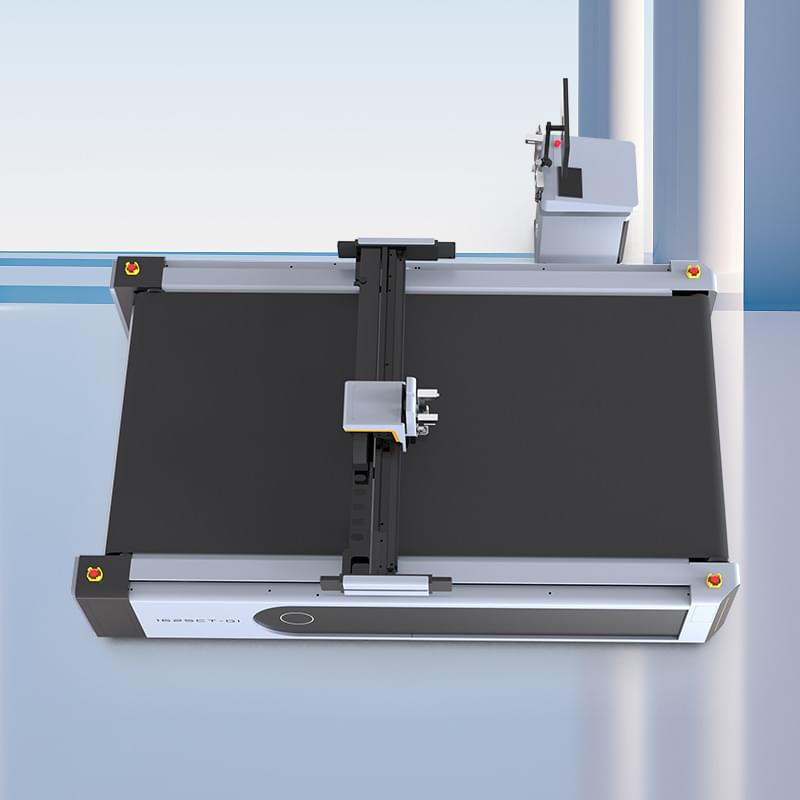

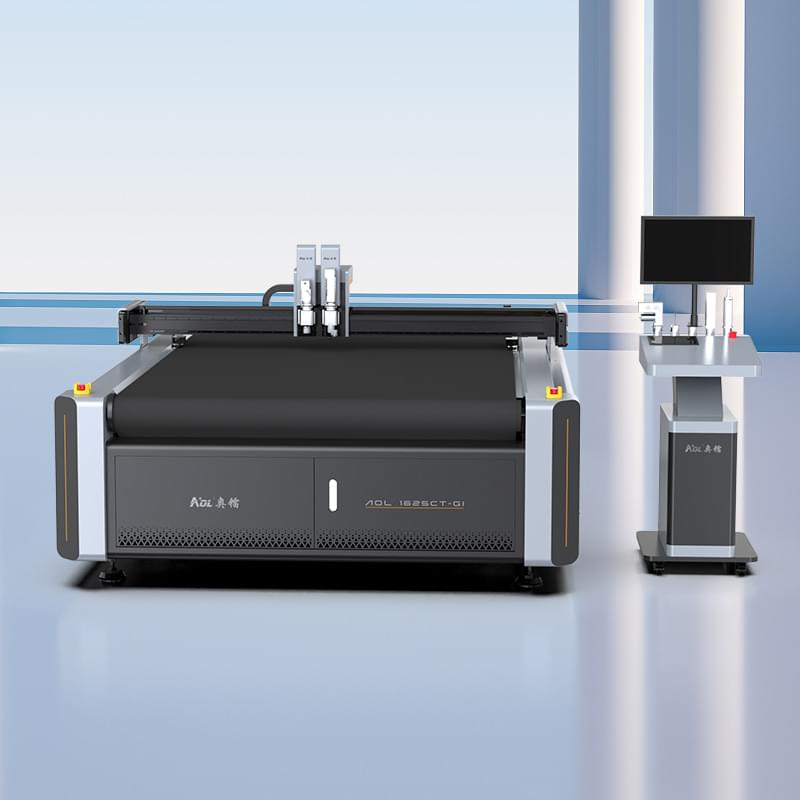

CNC knife cutting machines employ oscillating or rotary cutting blades to precisely cut through a wide array of flexible materials, including fabrics, foams, and composites. These machines excel in applications requiring intricate shapes and complex patterns, making them ideal for industries such as apparel, upholstery, automotive, and aerospace. With customizable tooling options and intuitive software interfaces, CNC knife cutting machines offer versatility and flexibility to accommodate diverse production requirements.

Cutting display

-1.jpg)

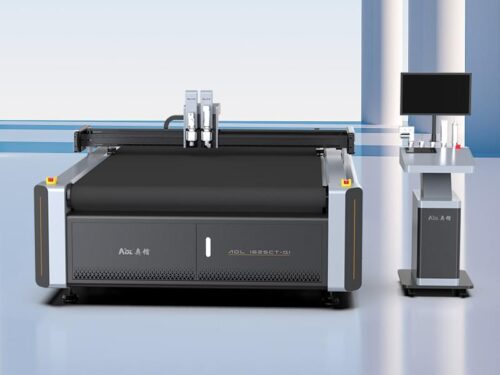

Specifications of CNC Industrial Fabric Cutter Machines

| Technical parameters / model | AOL-1625-ZS6 | AOL-1825-ZS8 | AOL-2125-ZS10 | Accept special model customization | ||

|---|---|---|---|---|---|---|

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

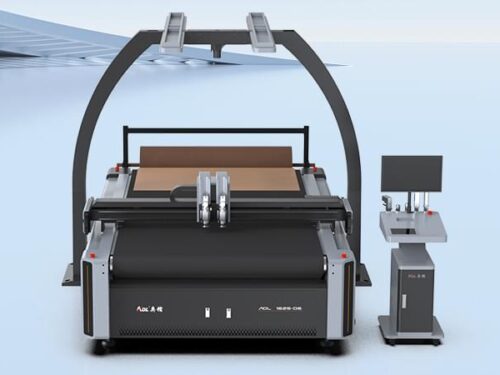

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

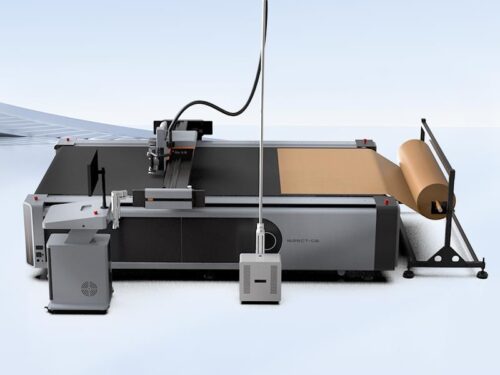

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | Glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, boron fiber, aramid fiber, ceramic fiber, soft glass, PVC, leather leather, sponge composite skin, XPE material, wire ring, leather, soft glass , silicone, rubber material etc composite soft material | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Imported servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Why Choose CNC Industrial Fabric Cutter Machines

Performance of CNC Industrial Fabric Cutter Machines

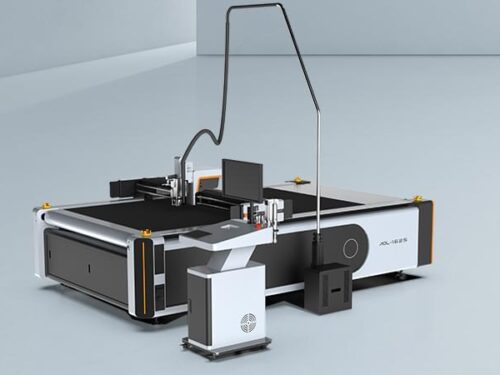

1. Infrared induction system, 360° surrounding safety, ensuring operator safety.

2. Complete camera positioning system, supporting ● or ten marks, etc., to improve work efficiency.

3. The solid aluminum honeycomb platform has good suction effect, ensuring that the platform is flat and will not deform after long-term use.

4. Flexible tool system, compatible with all AOL series tools.

5. Highly efficient anti-dry roll feeding system, completes feeding and cutting within 5 seconds; enabling the machine to achieve automatic continuous cutting.

6. Powerful CAD editing and design software, perfectly matched with a variety of software; and supports barcode reading to prevent operators from sending wrong cutting files and improve work efficiency.

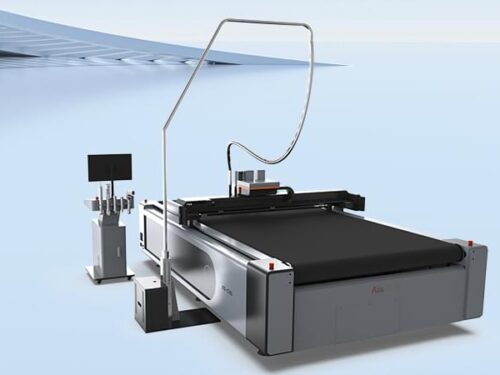

7. Parameter formulation system can adjust the best cutting parameters according to different materials to ensure the accuracy of each cutting.

8. The overall frame structure is designed by senior engineers in the industry. It is simple, stable, and easy to install and carry.

9. The precise knife setting system is easy to operate and can accurately control the depth of the knife and extend the use time of the mat.

10. Scientific and concise wiring system and chassis circuit design, stable and safe; equipped with all tool interfaces to support subsequent upgrades; easy to install and maintain.

Reasons for choosing AOL CNC equipment

1.AOL after-sales service team has more than 20 engineers.

2. There are at least 3 engineers serving one agent/customer, and they all can speak English.

3. We support complete user manual with videos and photos.

4. We support remote assistance to help you install and use the software.

5. We support 24*7 online guidance and services.

6. Our machines are guaranteed for 3 years (except felt, knives and blades), during this period, if there are any problems, we will replace them with new ones for free by DHL, and for knives, we will repair them for free within one year.

7. We promise to send out replacement parts within 24 hours.

8. We will form a service team for you, including AOL sales staff, AOL engineers, AOL sales managers, AOL sales directors and you (or your employees). If you have any questions, we will reply within 1 minute.

9. AOL software has free lifetime upgrades.

FAQ

1. Are you a trading company or a factory?

We are manufacturers.

2. When can we arrange shipment?

We usually arrange shipment?within 15 days after getting deposit, but customized machines should be more than 25 days.

3. Do you provide equipment operation training after sale?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

4. Can you customize the machine according to my request?

Yes. We have experienced engineers and technical team, can provide personalized service

Media of AOL

The price of CNC knife cutting machine, Please inquire and tell us your cutting material and size.

If you want to know the price of the digital gasket cutting machine, please send us the name, size and thickness of the material to be cut, so as to give you the most detailed quotation.

For more information, please consult:

Email: [email protected]

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/

Reviews

There are no reviews yet.